Abstract

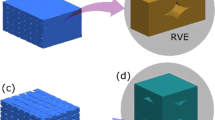

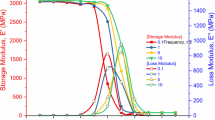

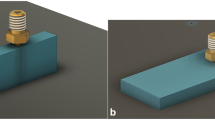

Fused deposition modelling (FDM) is an additive manufacturing method having the potential to fabricate functional components. As the inherent nature of additive structures, the component stiffness depends on the build parameters such as layer height and raster orientation in addition to the filament material properties. Even on FDM prints with 100% infill density, voids are formed along the interface of rasters and contribute to the characteristics of the component. The primary role of the present work is to determine elastic characteristics such as Young’s modulus, shear modulus and Poisson’s ratio of FDM components and study the effect of build parameters. The void geometry identified from the cross-sectional morphology was used to create a microscale representative volume element (RVE) model capturing the characteristics of the FDM print. The elastic constants of the microscale model RVE were estimated by volume average method and homogenised over the entire structure. The study also investigated the influence of layer height on the elastic behaviour of FDM components in two different raster orientations of 0° and 0°/90°. Both the conditions exhibited directional characteristics and the elasticity constants approaches filament characteristics with decreases in the layer height. The modulus of elasticity was found maximum in the direction of raster orientation, whereas the elasticity modulus along vertical direction exhibited the lowest. The components with 0°–90° raster orientation exhibited transversely isotropic characteristics. Thus, the actual cross-sectional morphology-based microscale numerical analysis can effectively predict the directional attributes of FDM prints.

Similar content being viewed by others

References

Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos B 143:172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Oropallo W, Piegl LA (2016) Ten challenges in 3D printing. Eng Comput 32:135–148. https://doi.org/10.1007/s00366-015-0407-0

Ning F, Cong W, Hu Z, Huang K (2017) Additive manufacturing of thermoplastic matrix composites using fused deposition modeling: a comparison of two reinforcements. J Compos Mater 51:3733–3742. https://doi.org/10.1177/0021998317692659

Yang C, Wang B, Li D, Tian X (2017) Modelling and characterisation for the responsive performance of CF/PLA and CF/PEEK smart materials fabricated by 4D printing. Virtual Phys Prototyp 12:69–76. https://doi.org/10.1080/17452759.2016.1265992

Singh R, Ranjan N (2018) Experimental investigations for preparation of biocompatible feedstock filament of fused deposition modeling (FDM) using twin screw extrusion process. J Thermoplast Compos Mater 31:1455–1469. https://doi.org/10.1177/0892705717738297

Mohan N, Senthil P, Vinodh S, Jayanth N (2017) A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys Prototyp 2759:47–59. https://doi.org/10.1080/17452759.2016.1274490

Kumar S, Kurth J-P (2010) Composites by rapid prototyping technology. Mater Des 31:850–856. https://doi.org/10.1016/j.matdes.2009.07.045

Levenhagen NP, Dadmun MD (2018) Interlayer diffusion of surface segregating additives to improve the isotropy of fused deposition modeling products. Polymer 152:35–41. https://doi.org/10.1016/j.polymer.2018.01.031

Boparai K, Singh R, Singh H (2015) Comparison of tribological behaviour for Nylon6-Al-Al2O3 and ABS parts fabricated by fused deposition modelling. Virtual Phys Prototyp 10:59–66. https://doi.org/10.1080/17452759.2015.1037402

Yamamoto BE, Trimble AZ, Minei B, Ghasemi Nejhad MN (2019) Development of multifunctional nanocomposites with 3-D printing additive manufacturing and low graphene loading. J Thermoplast Compos Mater 32:383–408. https://doi.org/10.1177/0892705718759390

Kaynak C, Varsavas SD (2018) Performance comparison of the 3D-printed and injection-molded PLA and its elastomer blend and fiber composites. J Thermoplast Compos Mater 32:501–520. https://doi.org/10.1177/0892705718772867

Ilardo R, Williams CB (2010) Design and manufacture of a Formula SAE intake system using fused deposition modeling and fiber reinforced composite materials. Rapid Prototyp J 16:174–179. https://doi.org/10.1108/13552541011034834

Prada JG, Cazon A, Carda J, Aseguinolaza A (2016) Direct digital manufacturing of an accelerator pedal for a formula student racing car. Rapid Prototyp J 22:311–321. https://doi.org/10.1108/RPJ-05-2014-0065

Klippstein H, Diaz A, Sanchez DC, Hassanin H, Zweiri Y (2017) Fused deposition modeling for unmanned aerial vehicles (UAVs): a review. Adv Eng Mater 20:1–17. https://doi.org/10.1002/adem.201700552

Cazón A, Prada JG, García E, Larraona GS, Ausejo S (2015) Pilot study describing the design process of an oil sump for a competition vehicle by combining additive manufacturing and carbon fibre layers. Virtual Phys Prototyp 10:149–162. https://doi.org/10.1080/17452759.2015.1076240

Javaid M, Haleem A (2018) Additive manufacturing applications in medical cases: a literature based review. Alex J Med 54:411–422. https://doi.org/10.1016/j.ajme.2017.09.003

Jain P, Kuthe AM (2013) Feasibility Study of manufacturing using rapid prototyping: FDM Approach. Procedia Eng 63:4–11. https://doi.org/10.1016/j.proeng.2013.08.275

Singh R, Singh S (2014) Development of nylon based FDM filament for rapid tooling application. J Inst Eng India Ser C 95:103–108. https://doi.org/10.1007/s40032-014-0108-2

Sunpreet S, Rupinder S (2016) Fused deposition modelling based rapid patterns for investment casting applications: a review. Rapid Prototyp J 22:123–143. https://doi.org/10.1108/RPJ-02-2014-0017

Jayanth N, Senthil P (2019) Application of 3D printed ABS based conductive carbon black composite sensor in void fraction measurement. Compos B 159:224–230. https://doi.org/10.1016/j.compositesb.2018.09.097

Isakov DV, Lei Q, Castles F, Stevens CJ, Grovenor CRM, Grant PS (2016) 3D printed anisotropic dielectric composite with meta-material features. Mater Des 93:423–430. https://doi.org/10.1016/j.matdes.2015.12.176

Gardner JM, Sauti G, Kim J, Cano RJ, Wincheski RA, Stelter CJ, Grimsley BW, Working DC, Siochi EJ (2016) 3-D printing of multifunctional carbon nanotube yarn reinforced components. Addit Manuf 12:38–44. https://doi.org/10.1016/j.addma.2016.06.008

Schmitz DP, Ecco LG, Dul S, Pereira ECL, Soares BG, Barra GMO, Pegoretti A (2018) Electromagnetic interference shielding effectiveness of ABS carbon-based composites manufactured via fused deposition modelling. Mater Today Commun 15:70–80. https://doi.org/10.1016/j.mtcomm.2018.02.034

Huang B, Singamneni S (2015) Raster angle mechanics in fused deposition modelling. J Compos Mater 49:363–383. https://doi.org/10.1177/0021998313519153

Dizon JRC, Espera AH Jr, Chen Q, Advincula RC (2018) Review: mechanical characterization of 3D-printed polymers. Addit Manuf. https://doi.org/10.1016/j.addma.2017.12.002

Ahn SH, Montero M, Odell D, Roundy S, Wright PK (2002) Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp J 8:248–257. https://doi.org/10.1108/13552540210441166

Sood AK, Ohdar RK, Mahapatra SS (2010) Parametric appraisal of mechanical property of fused deposition modelling processed parts. Mater Des 31:287–295. https://doi.org/10.1016/j.matdes.2009.06.016

Croccolo D, De Agostinis M, Olmi G (2013) Experimental characterization and analytical modelling of the mechanical behaviour of fused deposition processed parts made of ABS-M30. Comput Mater Sci 79:506–518. https://doi.org/10.1016/j.commatsci.2013.06.041

Dawoud M, Taha I, Ebeid SJ (2016) Mechanical behaviour of ABS: an experimental study using FDM and injection moulding techniques. J Manuf Process. https://doi.org/10.1016/j.jmapro.2015.11.002

Ziemian S, Okwara M, Ziemian CW (2015) Tensile and fatigue behavior of layered acrylonitrile butadiene styrene. Rapid Prototyp J 21:270–278. https://doi.org/10.1108/rpj-09-2013-0086

Abbott AC, Tandon GP, Bradford RL, Koerner H, Baur JW (2018) Process-structure-property effects on ABS bond strength in fused filament fabrication. Addit Manuf 19:29–38. https://doi.org/10.1016/j.addma.2017.11.002

Mcilroy C, Olmsted PD (2017) Disentanglement effects on welding behaviour of polymer melts during the fused-filament-fabrication method for additive manufacturing. Polymer 123:376–391. https://doi.org/10.1016/j.polymer.2017.06.051

Ravindrababu S, Govdeli Y, Wong ZW, Kayacan E (2018) Evaluation of the influence of build and print orientations of unmanned aerial vehicle parts fabricated using fused deposition modeling process. J Manuf Process 34:659–666. https://doi.org/10.1016/j.jmapro.2018.07.007

Motaparti KP, Taylor G, Leu MC, Chandrashekhara K, Castle J, Matlack M (2017) Experimental investigation of effects of build parameters on flexural properties in fused deposition modelling parts. Virtual Phys Prototyp 12:207–220. https://doi.org/10.1080/17452759.2017.1314117

Jiang S, Liao G, Xu D, Liu F, Li W, Cheng Y, Li Z, Xu G (2019) Mechanical properties analysis of polyetherimide parts fabricated by fused deposition modeling. High Perform Polym 31:97–106. https://doi.org/10.1177/0954008317752822

Wang L, Gardner DJ (2017) Effect of fused layer modeling (FLM) processing parameters on impact strength of cellular polypropylene. Polymer 113:74–80. https://doi.org/10.1016/j.polymer.2017.02.055

Chacón JM, Caminero MA, García-Plaza E, Núñez PJ (2017) Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater Des 124:143–157. https://doi.org/10.1016/j.matdes.2017.03.065

Rajpurohit SR, Dave HK (2018) Effect of process parameters on tensile strength of FDM printed PLA part. Rapid Prototyp J 24:1317–1324. https://doi.org/10.1108/RPJ-06-2017-0134

Lanzotti A, Grasso M, Staiano G, Martorelli M (2015) The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp J 21:604–617. https://doi.org/10.1108/rpj-09-2014-0135

Tymrak BM, Kreiger M, Pearce JM (2014) Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater Des 58:242–246. https://doi.org/10.1016/j.matdes.2014.02.038

Bhalodi D, Zalavadiya K, Gurrala PK (2019) Influence of temperature on polymer parts manufactured by fused deposition modeling process. J Braz Soc Mech Sci Eng 41:1–11. https://doi.org/10.1007/s40430-019-1616-z

Casavola C, Cazzato A, Moramarco V, Pappalettere C (2016) Orthotropic mechanical properties of fused deposition modelling parts described by classical laminate theory. Mater Des 90:453–458. https://doi.org/10.1016/j.matdes.2015.11.009

Liu X, Shapiro V (2016) Homogenization of material properties in additively manufactured structures. Comput Aided Des 78:71–82. https://doi.org/10.1016/j.cad.2016.05.017

Domingo-Espin M, Puigoriol-Forcada JM, Garcia-Granada A-A, Llumà J, Borros S, Reyes G (2015) Mechanical property characterization and simulation of fused deposition modeling Polycarbonate parts. Mater Des 83:670–677. https://doi.org/10.1016/j.matdes.2015.06.074

Rodriguez JF, Thomas JP, Renaud JE (2000) Characterization of the mesostructure of styrene materials. Rapid Prototyp J 6:175–186. https://doi.org/10.1108/13552540010337056

Magalhães LC, Volpato N, Luersen MA (2014) Evaluation of stiffness and strength in fused deposition sandwich specimens. J Braz Soc Mech Sci Eng 36:449–459. https://doi.org/10.1007/s40430-013-0111-1

Guessasma S, Belhabib S, Nouri H (2015) Significance of pore percolation to drive anisotropic effects of 3D printed polymers revealed with X-ray μ-tomography and fi nite element computation. Polymer 81:29–36. https://doi.org/10.1016/j.polymer.2015.10.041

Rodríguez JF, Thomas JP, Renaud JE (2003) Mechanical behavior of acrylonitrile butadiene styrene fused deposition materials modeling. Rapid Prototyp J 9:219–230. https://doi.org/10.1108/13552540310489604

Omairey SL, Dunning PD, Sriramula S (2018) Development of an ABAQUS plugin tool for periodic RVE homogenisation. Eng Comput 35:1–11. https://doi.org/10.1007/s00366-018-0616-4

Calneryte D, Barauskas R, Milasiene D, Maskeliunas R, Neciunas A, Ostreika A, Patasius M, Krisciunas A (2018) Multi-scale finite element modeling of 3D printed structures subjected to mechanical loads. Rapid Prototyp J 24:177–187. https://doi.org/10.1108/RPJ-05-2016-0074

Somireddy M, Czekanski A, Singh CV (2018) Development of constitutive material model of 3D printed structure via FDM. Mater Today Commun 15:143–152. https://doi.org/10.1016/j.mtcomm.2018.03.004

Barbero EJ (2011) Finite element analysis of composite materials. CRC Press, Boca Raton

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anoop, M.S., Senthil, P. Homogenisation of elastic properties in FDM components using microscale RVE numerical analysis. J Braz. Soc. Mech. Sci. Eng. 41, 540 (2019). https://doi.org/10.1007/s40430-019-2037-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-019-2037-8