Abstract

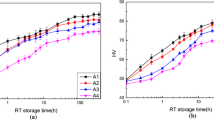

Two-step aging with the different natural aging times and chemical compositions was carried out in Al–Mg–Si alloys to investigate the clustering and two-step aging behavior. The activation energies of cluster formation through the Kissinger method were analyzed as 69.4, 67.3 and 73.8 kJ/mol for the 9M4S, 6M6S and 3M10S, respectively. A similar hardness was identified for short-term natural aging for 3.6 ks regardless of the Mg/Si ratio. On the other hand, a lower hardness was identified in the 3M10S (Mg/Si = 0.3) than in 9M4S (Mg/Si = 2.5) and 6M6S (Mg/Si = 1) for long-term natural aging for 4838.4 ks. The hardness increase during the two-step aging was due to the formation of a β″ phase during artificial aging based on structure analysis of high resolution transmission electron microscope images. There was a hardness decrease at the initial stage of the two-step aging at 170 °C in the case of long-term naturally-aged specimens. The hardness decrease was caused by the partial dissolution of the Mg–Si co-cluster, which was influenced by the Mg/Si ratio. Meanwhile, the hardness increase during two-step aging was promoted for 6M6S and the higher number density of the β″ phase was confirmed.

Similar content being viewed by others

References

G.A. Edwards, K. Stiller, G.L. Dunlop, M.J. Couper, Acta Mater. 46, 3893 (1998)

K. Matsuda, Y. Sakaguchi, Y. Miyata, Y. Uetani, T. Sato, A. Kamio, S. Ikeno, J. Mater. Sci. 35, 179 (2000)

S.J. Andersen, C.D. Marioara, A.G. Froseth, R. Vissers, H.W. Zandbergen, Mater. Sci. Eng. A 390, 127 (2005)

C.D. Marioara, S.J. Andersen, H.W. Zandbergen, R. Holmestad, Metall. Mater. Trans. A 36, 691 (2005)

S. Kitaoka, S. Fujikura, A. Kamio, Microstructure and Properties of Aluminum (The Japan Institute of Light Metals, Nomi, 1991), p. 278

D.W. Pashley, J.W. Rhodes, A. Sendorek, J. Inst. Met. 94, 41 (1966)

D.W. Pashley, M.H. Jacobs, J.T. Vietz, Philos. Mag. 51, 51 (1967)

I. Dutta, S.M. Allen, J. Mater. Sci. Lett. 10, 323 (1991)

J. Kim, E. Kobayashi, T. Sato, Mater. Trans. 56, 1771 (2015)

A. Serizawa, S. Hirosawa, T. Sato, Mater. Sci. Forum 519–521, 245 (2006)

K. Yamada, T. Sato, Akihiko Kamio. J. Jpn. Inst. Light Met. 51(4), 215 (2001)

A. Serizawa, T. Sato, Aluminium Alloys (ICAA-11), vol. 1, eds. J. Hirsch, B. Skrotzki, G. Gottstein (2008), p. 915

A. Cuniberti, A. Tolley, M.V.C. Riglos, R. Giovachini, Mater. Sci. Eng. A 527, 5307 (2010)

M.D.H. Lay, H.S. Zurob, C.R. Hutchinson, T.J. Bastow, A.J. Hill, Metall. Mater. Trans. A 43, 4507 (2012)

S. Kim, J. Kim, E. Kobayashi, T. Sato, Mater. Trans. 55, 1647 (2014)

M. Torsaeter, H.S. Hasting, W. Lefebvre, C.D. Marioara, J.C. Walmsley, S.J. Andersen, R. Holmestad, J. Appl. Phys. 108, 073527 (2010)

A. Gaber, A.M. Ali, K. Matsuda, T. Kawabata, T. Yamazaki, S. Ikeno, J. Alloys Compd. 432, 145 (2007)

A. Gaber, N. Afify, M.S. Mostafa, G. Abbady, J. Alloy. Compd. 429, 295 (2009)

W.F. Miao, D.E. Laughlin, Metall. Mater. Trans. A 31, 361 (2000)

A. Serizawa, S. Hirosawa, T. Sato, Metall. Mater. Trans. A 39, 243 (2008)

K. Yamada, T. Sato, A. Kamio, Mater. Sci. Forum 331–337, 669 (2000)

H. Yinnon, D.R. Uhlmann, J. Non-Cryst, Solids 54, 253 (1983)

A. Gaber, M.A. Gaffar, M.S. Mostafa, E.F. Abo Zeid, J. Alloy. Compd. 429, 167 (2007)

M.J. Starink, Thermochim. Acta 404, 163 (2003)

K. Matsuda, S. Ikeno, J. Jpn. Inst. Light Met. 50, 23 (2000)

V. Fallah, B. Langelier, N. Ofori-Opoku, B. Raeisinia, N. Provatas, S. Esmaeili, Acta Mater. 103, 290 (2016)

Y. Aruga, M. Kozuka, Y. Takaki, T. Sato, Mater. Sci. Eng. A 631, 86 (2015)

Y. Aruga, S. Kim, M. Kozuka, E. Kobayashi, T. Sato, Mater. Sci. Eng. A 718, 371 (2018)

Y. Aruga, M. Kozuka, T. Sato, J. Alloys Compd. 739, 1115 (2018)

J. Kim, S. Kim, E. Kobayashi, T. Sato, Mater. Trans. 55, 768 (2014)

Acknowledgements

This work was supported by the Development of hot/warm forming-heat treatment integrated process for high strength aluminum alloy (PEO18272) of the Korea Institute of Industrial Technology. The authors are grateful to UACJ Corp. for the material supply. The authors thank Mr. Jong-gyun Kang, Center for University Research Facility (CURF) at Chonbuk National University, for TEM images.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Im, J., Jeon, J., Song, M. et al. Influence of Natural Aging Time and Mg/Si Ratio (Mg + Si = 1.3 mass%) on the Two-Step Aging Behavior in Al–Mg–Si Alloys. Met. Mater. Int. 25, 860–868 (2019). https://doi.org/10.1007/s12540-019-00257-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00257-8