Abstract

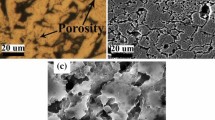

Wear behavior of a harmonic structured 304L austenitic stainless steel with periodically distributed fine and coarse grains was examined and compared with a sintered non-harmonic structured 304L stainless steel and a low carbon conventional 304 stainless steel using fretting wear tests at varying loads in ball-on-flat contact configuration. Characterization was accomplished using scanning electron microscope, energy-dispersive spectroscopy, optical profilometry and Raman spectroscopy. Coefficient of friction and wear volume were minimum at intermediate normal load of 5 N, whereas maximum at 10 N for the harmonic stainless steel compared to other two steels. Harmonically distributed fine- and coarse-grained structure attributes to the higher wear rate of the harmonic structured steel at higher load because of differential interaction of the ball with the harmonically distributed hard (fine) and relatively soft (coarse) regions.

Similar content being viewed by others

References

G.E. Dieter, Mechanical Metallurgy, McGraw-Hill Book Company, Singapore, 1988 (SI, Metric Edition)

B.S. Murty and S. Ranganathan, Novel Materials Synthesis by Mechanical Alloying/Milling, Int. Mater. Rev., 1998, 43, p p101–p141

Y. Zhao, X. Liao, Z. Jin, R. Valiev, and Y. Zhu, Microstructures and Mechanical Properties of Ultrafine Grained 7075 Al Alloy Processed by ECAP and Their Evolutions During Annealing, Acta Mater., 2004, 52, p 4589–4599

T. Roland, D. Retraint, K. Lu, and J. Lu, Enhanced Mechanical Behavior of a Nanocrystallised Stainless Steel and its Thermal Stability, Mater. Sci. Eng. A, 2007, 445–446, p 281–288

P.K. Rai, V. Pandey, K. Chattopadhyay, L.K. Singhal, and V. Singh, Effect of Ultrasonic Shot Peening on Microstructure and Mechanical Properties of High-Nitrogen Austenitic Stainless Steel, J. Mater. Eng. Perform., 2014, 23, p 4055–4064

K. Lu, J.T. Wang, and W.D. Wei, A New Method for Synthesizing Nanocrystalline Alloys, J. Appl. Phys., 1991, 69, p 522–524

U. Erb, A.M. El-Sherik, G. Palumbo, and K.T. Aust, Synthesis, Structure and Properties of Electroplated Nanocrystalline Materials, Nanostruct. Mater., 1993, 2, p 383–390

Y. Wang, M. Chen, F. Zhou, and E. Ma, High Tensile Ductility in a Nanostructured Metal, Nature, 2002, 419, p 912–914

C.C. Koch, Optimization of Strength and Ductility in Nanocrystalline and Ultrafine Grained Metals, Scr. Mater., 2003, 49, p 657–662

Q.H. Bui, Heterogeneous Plastic Deformation in Bimodal Bulk Ultrafine-Grained Nickel, J. Mater. Sci., 2012, 47, p 1902–1909

Z. Zhang, D. Orlov, S.K. Vajpai, B. Tong, and K. Ameyama, Importance of Bimodal Structure Topology in the Control of Mechanical Properties of a Stainless Steel, Adv. Eng. Mater., 2015, 17, p 791–795

C. Sawangrat, S. Kato, S. Orlov, and K. Ameyama, Harmonic-Structured Copper: Performance and Proof of Fabrication Concept Based on Severe Plastic Deformation of Powders, J. Mater. Sci., 2014, 49, p 6579–6585

O.P. Ciuca, M. Ota, S. Deng, and K. Ameyama, Harmonic Structure Design of a SUS329J1 Two Phase Stainless Steel and Its Mechanical Properties, Mater. Trans., 2013, 54, p 1629–1633

D. Orlov, H. Fujiwara, and K. Ameyama, Obtaining Copper with Harmonic Structure for the Optimal Balance of Structure—Performance Relationship, Mater. Trans., 2013, 54, p 1549–1553

C. Sawangrat, O. Yamaguchi, S.K. Vajpai, and K. Ameyama, Application of Harmonic Structure Design to Biomedical Co-Cr-Mo Alloy for Improved Mechanical Properties, Mater. Trans., 2014, 55, p 99–105

S.K. Vajpai, K. Ameyama, M. Ota, T. Watanabe, R. Maeda, T. Sekiguchi, G. Dirass, and D. Tingaud, High Performance Ti-6Al-4V Alloy by Creation of Harmonic Structure Design, IOP Conf. Series: Mater. Sci. Eng., 2014, 63, p 012030

E. Rabinowicz, Friction and Wear of Materials, 2nd ed., Wiley-Intersciense, New York, 1995

R. Mishra, B. Basu, and R. Balasubramaniam, Effect of Grain Size on the Tribological Behavior of Nanocrystalline Nickel, Mater. Sci. Eng. A, 2004, 373, p 370–373

Y.S. Zhang, Z. Han, and K. Lu, Fretting Wear Behavior of Nanocrystalline Surface Layer of Copper Under Dry Condition, Wear, 2008, 265, p 396–401

R. Sahoo, B.B. Jha, T.K. Sahoo, and D. Sahoo, Effect of Microstructural Variation on Dry Sliding Wear Behavior of Ti-6Al-4V Alloy, J. Mater. Eng. Perform., 2014, 23, p 2092–2102

A.M. Xavior and M. Adithan, Determining the Influence of Cutting Fluids on Tool Wear and Surface Roughness During Turning of AISI, 304 Austenitic Stainless Steel, J. Mater. Process. Tech., 2009, 209, p 900–909

Z. Zhang, S.K. Vajpai, D. Orlov, and K. Ameyama, Improvement of Mechanical Properties in SUS304L Steel Through the Control of Bimodal Microstructure Characteristics, Mater. Sci. Eng. A, 2014, 598, p 106–113

P.J. Blau, Running-in: Art or Engineering?, J. Mater. Eng., 1991, 13, p 47–53

R. Budynas and K. Nisbett, Shigley’s Mechanical Engineering Design, 8th ed., McGraw-Hill, New York City, 2008

P.Q. Wu, H. Chen, M. Van Stappen, L. Stals, and J.P. Celis, Comparison of Fretting Wear of Uncoated and PVD TiN Coated High-Speed Steel Under Different Testing Conditions, Surf. Coat. Tech., 2000, 127, p 114–119

K. Sikdar, S. Shekhar, and K. Balani, Fretting Wear of Mg-Li-Al Based Alloys, Wear, 2014, 318, p 177–187

X.Y. Wang and D.Y. Li, Mechanical, Electrochemical and Tribological Properties of Nano-crystalline Surface of 304 Stainless Steel, Wear, 2003, 255, p 836–845

D.A. Brown, D. Cunningham, and W.K. Glass, The Infrared and Raman Spectra of Chromium (III) Oxide, Spectrochim. Acta, 1967, 24A, p 965–968

S.J. Oh, D.C. Cook, and H.E. Townsend, Characterization of Iron Oxides Commonly Formed as Corrosion Products on Steel, Hyperfine Interact., 1998, 112, p 59–65

Acknowledgments

We are thankful to Prof. K. Balani of Dept. of Materials Science and Engineering, IIT Kanpur for allowing us to use the fretting wear testing facility of his laboratory.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rai, P.K., Shekhar, S., Nakatani, M. et al. Wear Behavior of Harmonic Structured 304L Stainless Steel. J. of Materi Eng and Perform 26, 2608–2618 (2017). https://doi.org/10.1007/s11665-017-2719-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2719-2