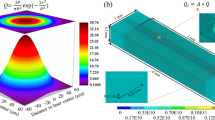

The influence of temperature fields on the structure and properties of corrosion-resistant chromium steels under different modes of laser treatment is investigated. A model of heat transfer under laser impact on target is used to plot thermal fields and cycles and cooling rates. It is shown that the model used for computing thermal fields gives tentative geometric sizes of the fusion zones under laser treatment and selective laser fusion. The cooling rate is shown to have decisive influence on the structure of corrosion-resistant steels after laser treatment with surface fusion in devices for pulsed, continuous, and selective laser melting.

Similar content being viewed by others

References

I. Hemmati, V. Ocelik, and J. T. M. De Hosson, “Microstructural characterization of AISI 431 martensitic stainless steel laser-deposited coatings,” J. Mater. Sci., 46(10), 3405 – 3414 (2011).

B. Mahmoudi, M. J. Torkamany, A. R. Sabour Rouh Aghdam et al., “Laser surface hardening of AISI 420 stainless steel treated by pulsed Nd:YAG laser,” Mater. Design, 31(5), 2533 – 2560 (2010).

B. Gaković, M. Trtica, S. Petrovic, et al., “Surface structures formed on AISI 420 stainless steel by pulsed laser irradiation,” Mater. Sci. Forum, Trans. Tech. Publ., 494, 309 – 314 (2005).

Yu.M. Lakhtin and T. V. Tarasova, “Surface hardening of corrosion-resistant steels by laser radiation,” Izv. Vysh. Uchebn. Zaved., Mashinostr., No. 2, 124 – 127 (1984).

T. V. Tarasova, Development of the Process of Laser Hardening of Corrosion-Resistant Chromium Steels, Author’s Abstract of Candidate’s Thesis [in Russian], MADI, Moscow (1986).

T. V. Tarasova, “Prospects of the use of laser radiation for raising the wear resistance of corrosion-resistant steels,” Met. Sci. Heat Treat., 52(5 – 6), 284 – 288 (2010).

S. N. Grigor’ev and T. V. Tarasova, “Possibilities of the process of additive production for making complex-profile parts and depositing functional coatings from metallic powders,” Metalloved. Term. Obrab. Met., No. 10, 5 – 11 (2015).

T. V. Tarasova and A. P. Nazarov, “A study of the process of selective laser melting of corrosion-resistant chromium steel 20Kh13,” Vestn. Mashinostr., No. 8, 24 – 27 (2015).

I. Yadroitsev, S. Marques, A. Domashenkov, et al., “Strategy toward the manufacturing of fully dense parts from AISI 420 stainless steel by selective laser melting,” in: RAPDASA 2014 (2014).

A. Okunkova, M. Volosova, P. Peretyagin, et al., “Experimental approbation of selective laser melting of powders by the use of non-Gaussian power density distributions,” Phys. Proc., 56, 48 – 57 (2014).

I. V. Zhirnov, P. A. Podrabinnik, A. A. Okunkova, et al., “Laser beam profiling: experimental study of its influence on single-track formation by selective laser melting,” Mechan. Ind., 16, 709 (2015).

A. A. Filatova, T. V. Tarasova, and K. E. Protasov, “Methods of control of the granulometric composition of powders of domestic corrosion-resistant steels,” Vestn. Mos. Gos. Tekh. Univ. STANKIN, No. 1(36), 53 – 58 (2016).

R. S. Khmyrov, S. N. Grigoriev, A. A. Okunkova, et al., “On the possibility of selective laser melting of quartz glass,” Phys. Proc., 56, 345 – 356 (2014).

I. O. Kovaleva, S. N. Grigoriev, and A. V. Gusarov, “Non-disturbing boundary conditions for modeling of laser material processing,” Phys. Proc., 56, 421 – 428 (2014).

B. I. Leonovich, “Thermodynamic analysis and phase equilibria in the iron-chromium-carbon system,” Vestn. Yuzh.-Ural. Gos. Univ., Metallurgiya, No. 36(169), 4 – 12 (2009).

D. R. Lide, CRC Handbook of Chemistry and Physics, Vol. 85, CRC Press (2004), 2137 p.

E. I. Kazantsev, Industrial Furnaces. A Guide for Computations and Design [in Russian], Metallurgiya, Moscow (1975), 386 p.

V. S. Chirkin, Thermophysical Properties of Nuclear Engineering Materials [in Russian], Atomizdat, Moscow (1968), 156 p.

A. Domashenkov, Fabrication des Moules Pour Moulage par Injection au Moyen de la Fusion Sélective par Laser. Diplôme de Master Recherche Ingénierie des Matériaux et Procédés Spécialité: Mécanique et Ingénierie, Ecole Nationale d’Ingénieurs de Saint-Etienne, France (2013).

The work has been performed with financial support of the Ministry of Education of the Russian Federation within State Assignment No. 11.1267.2017/PCh.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 7, pp. 37 – 44, July, 2017.

Rights and permissions

About this article

Cite this article

Tarasova, T.V., Gusarov, A.V., Protasov, K.E. et al. Effect of Thermal Fields on the Structure of Corrosion-Resistant Steels Under Different Modes of Laser Treatment. Met Sci Heat Treat 59, 433–440 (2017). https://doi.org/10.1007/s11041-017-0168-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-017-0168-z