Abstract

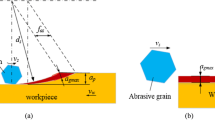

An effective finite element (FE) simulation model characterizing the material removal behavior of TiCp/Ti-6Al-4V titanium matrix composites in high-speed grinding process was developed when considering consecutive action of two abrasive grains. The resultant stress and grinding force have been analyzed to study the crack propagation behavior. The effect of the undeformed chip thickness on the ground surface defects was discussed. It was found that in the material removal process of PTMCs, the brittle removal of TiCp and the plastic removal of Ti-6Al-4V matrix would happen simultaneously until the reinforcing particle completely failed in the grinding process. The maximum Mises stress and single-grain grinding forces fluctuate weakly and smoothly once the crack is produced in the reinforcing TiCp. As for the reinforcing TiCp without crack inside, the crushing depth increases with the increase of the undeformed chip thickness in grinding. However, as for the TiCp with residual crack inside, due to the stress concentration in the tip of the crack, the TiCp is always cracked in chunks when the undeformed chip thickness changes from 0.3 to 0.9 μm in grinding. Finally, the FE simulation results are validated true through the high-speed grinding experiment of PTMCs.

Similar content being viewed by others

References

Rastegari HA, Asgari S, Abbasi SM (2011) Producing Ti-6Al-4V/TiC composite with good ductility by vacuum induction melting furnace and hot rolling process. Mater Des 32(10):5010–5014

Huang LJ, Geng L, Peng HX (2010) In situ (TiBw +TiCp)/Ti6Al4V composites with a network reinforcement distribution. Mater Sci Eng A 527:6723–6727

Zhang YZ, Sun JC, Vilar R (2011) Characterization of (TiB+TiC)/TC4 in situ titanium matrix composites prepared by laser direct deposition. J Mater Process Technol 211:597–601

Choi BJ, Kim ILY, Lee YZ, Kim YJ (2014) Microstructure and friction/wear behavior of (TiB+TiC) particulate-reinforced titanium matrix composites. Wear 318:68–77

Jackson MJ, Davis CJ, Hitchiner MP, Mills B (2001) High-speed grinding with CBN grinding wheels-applications and future technology. J Mater Process Technol 110:78–88

Zhang DK, Li CH, Zhang YB, Jia DZ, Zhang XW (2015) Experimental research on the energy ratio coefficient and specific grinding energy in nanoparticle jet MQL grinding. Int J Adv Manuf Technol 78:1275–1288

Zhang XP, Li CH, Zhang YB, Zhang XW (2016) Performances of Al2O3/SiC hybrid nanofluids in minimum-quantity lubrication grinding. Int J Adv Manuf Technol 86:3427–3441

Zhang DK, Li CH, Jia DZ (2015) Specific grinding energy and surface roughness of nanoparticle jet minimum quantity lubrication in grinding. Chin J Aeronaut 28(2):570–581

Mao C, Zhang J, Huang Y, Zou HF, Huang XM, Zhou ZX (2013) Investigation on the effect of nanofluid parameters on MQL grinding. Mater Manuf Process 28:436–442

Mao C, Zou HF, Zhou X, Huang Y, Gan HY, Zhou ZX (2014) Analysis of suspension stability for nanofluid applied in minimum quantity lubricant grinding. Int J Adv Manuf Technol 71:2073–2081

Qi H, Wen DH, Yuan QL, Zhang L, Chen ZZ (2017) Numerical investigation on particle impact erosion in ultrasonic-assisted abrasive slurry jet micro-machining of glasses. Powder Technol 314:627–634

Qi H, Wen DH, Lu CD, Li G (2016) Numerical and experimental study on ultrasonic vibration-assisted micro-channelling of glasses using an abrasive slurry jet. Int J Mech Sci 110:94–107

Thiagarajan C, Sivaramakrishnan R, Somasundaram S (2011) Experimental evaluation of grinding forces and surface finish in cylindrical grinding of Al/SiC metal matrix composites. Proc Inst Mech Eng B J Eng Manuf 225(9):1606–1614

Huang ST, Yu XL, Wang FS, Xu LF (2015) A study on chip shape and chip-forming mechanism in grinding of high volume fraction SiC particle reinforced Al-matrix composites. Int J Adv Manuf Technol 80:1927–1932

Blau PJ, Jolly BC (2009) Relationships between abrasive wear, hardness, and grinding characteristics of titanium-based metal-matrix composites. J Mater Eng Perform 18(4):424–432

Zhu Y, Kishawy HA (2005) Influence of alumina particles on the mechanics of machining metal matrix composites. Int J Mach Tools Manuf 45:389–398

Pramanik A, Zhang LC, Arsecularatne JA (2007) An FEM investigation into the behavior of metal matrix composites: tool–particle interaction during orthogonal cutting. Int J Mach Tools Manuf 47(10):1497–1506

Ghandehariun A, Kishawy H, Balazinski M (2016) On machining modeling of metal matrix composites: a novel comprehensive constitutive equation. Int J Mech Sci 107:235–241

Umer U, Ashfaq M, Qudeiri JA (2015) Modeling machining of particle-reinforced aluminum-based metal matrix composites using cohesive zone elements. Int J Adv Manuf Technol 78:1171–1179

Dandekar CR, Shin YC (2009) Multi-step 3-D finite element modeling of subsurface damage in machining particulate reinforced metal matrix composites. Compos A: Appl Sci Manuf 40:1231–1239

Azarhoushang B, Tawakoli T (2011) Development of a novel ultrasonic unit for grinding of ceramic matrix composites. Int J Adv Manuf Technol 57:945–955

Liu CJ, Ding WF, Yu TY, Yang CY (2018) Materials removal mechanism in high-speed grinding of particulate reinforced titanium matrix composites. Precis Eng 51:68–77

Wang T, Xie LJ, Wang XB (2015) Simulation study on defect formation mechanism of the machined surface in milling of high volume fraction SiCp/Al composite. Int J Adv Manuf Technol 79:1185–1194

Wang BB, Xie LJ, Chen XL, Wang XB (2016) The milling simulation and experimental research on high volume fraction of SiCp/Al. Int J Adv Manuf Technol 82:809–816

Kotkunde N, Krishnamurthy HN, Puranik P, Gupta AK, Singh SK (2014) Microstructure study and constitutive modeling of Ti–6Al–4V alloy at elevated temperatures. Mater Des 54:96–103

Akbari M, Buhl S, Leinenbach C, Wegener K (2016) A new value for Johnson Cook damage limit criterion in machining with large negative rake angle as basis for understanding of grinding. J Mater Process Technol 234:58–71

Guerrini G, Bruzzone AAG, Crenna F (2017) Single grain grinding: an experimental and FEM assessment. Procedia CIRP 62:287–292

Fu DK, Ding WF, Yang SB, Miao Q, Fu YC (2017) Formation mechanism and geometry characteristics of exit-direction burrs generated in surface grinding of Ti-6Al-4V titanium alloy. Int J Adv Manuf Technol 89:2299–2313

Ghandehariun A, Kishawy HA, Umer U, Hussein MH (2016) Analysis of tool-particle interactions during cutting process of metal matrix composites. Int J Adv Manuf Technol 82:143–152

Gao CY, Zhang LC (2013) Effect of cutting conditions on the serrated chip formation in high-speed cutting. Mach Sci Technol 17(1):26–40

Chen G, Ren C, Yang XY, Jin XM, Guo T (2011) Finite element simulation of high-speed machining of titanium alloy (Ti–6Al–4V) based on ductile failure model. Int J Adv Manuf Technol 56:1027–1038

Masanta M, Shariff SM, Choudhury AR (2011) Evaluation of modulus of elasticity, nano-hardness and fracture toughness of TiB2-TiC-Al2O3 composite coating developed by SHS and laser cladding. Mater Sci Eng A 528:5327–5335

Ding WF, Zhu YJ, Zhang LC, Xu JH, Fu YC, Liu WD, Yang CY (2015) Stress characteristics and fracture wear of brazed CBN grains in monolayer grinding wheels. Wear 332-333:800–809

Zhu D, Yan S, Li B (2014) Single-grit modeling and simulation of crack initiation and propagation in SiC grinding using maximum undeformed chip thickness. Comput Mater Sci 92:13–21

Chen JY, Xu XP (2014) Tribological characteristics in high-speed grinding of alumina with brazed diamond wheels. Int J Adv Manuf Technol 71:1579–1585

Li Z, Ding WF, Liu CJ, Su HH (2016) Prediction of grinding temperature of PTMCs based on the varied coefficients of friction in conventional-speed and high-speed surface grinding. Int J Adv Manuf Technol 90:2335–2344

Xu XP, Li Y, Malkin S (2001) Forces and energy in circular sawing and grinding of granite. J Manuf Sci Eng 123(1):13–22

Funding

The authors gratefully acknowledge the financial support for this work from the National Natural Science Foundation of China (No. 51775275), the Fundamental Research Fund for the Central University (No. NE2014103), and the Foundation of Graduate Innovation Center in NUAA (No. KFJJ20170527).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, H., Ding, W. & Liu, C. Material removal mechanism of PTMCs in high-speed grinding when considering consecutive action of two abrasive grains. Int J Adv Manuf Technol 100, 153–165 (2019). https://doi.org/10.1007/s00170-018-2685-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2685-3