Abstract

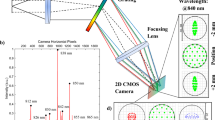

Touching screens as a key component of smart devices play a vital role in exerting normal function and user experience. Usually, defective products containing deep tiny cracks, impurities, or microbubbles generated in the manufacturing process are difficult to be detected by the present methods. The existence of such tiny defects potentially damages the integrated function of smart devices, even jeopardizes the health of users. The precise identification of microscopic defects buried in deep touching screens is great in demand. In this work, we built a spectral-domain optical coherence tomography (SD-OCT) system with suitable imaging depth and spatial resolution and carried out nondestructive imaging of endogenic micro-bubbles generated in the bonding process of the screen. Using SD-OCT, we obtained in situ 2D, 3D imaging of microbubbles to show quantitative information of the defects including exact size, shape, and spatial location, which help to analyze the occurring stage of bubble defects in the manufacturing process with improving accuracy. This provides a useful tool for the quality monitoring of the screen in industrial manufacture, which cannot be attainable by the common approaches.

Similar content being viewed by others

References

J.-H. Back, D. Baek, J.-W. Park et al., Shock absorption of semi-interpenetrating network acrylic pressure-sensitive adhesive for mobile display impact resistance. Int. J. Adhes. Adhes. 99, 102558 (2020)

S.-S. Baek, S.-H. Hwang, Preparation of biomass-based transparent pressure sensitive adhesives for optically clear adhesive and their adhesion performance. Eur. Polymer J. 92, 97–104 (2017)

C.-H. Park, S.-J. Lee, T.-H. Lee et al., Characterization of an acrylic polymer under hygrothermal aging as an optically clear adhesive for touch screen panels. Int. J. Adhes. Adhes. 63, 137–144 (2015)

S.-T. Chen, C.-C. Liu, C.-Y. Fu, Study of a high-efficiency, -precision, one-shot OCA dispensing technique. J. Mater. Process. Technol. 213(7), 1059–1067 (2013)

C.-J. Lu, D.-M. Tsai, Automatic defect inspection for LCDs using singular value decomposition. Int. J. Adv. Manuf. Technol. 25(1–2), 53–61 (2004)

R. Stojanovic, P. Mitropulos, C. Koulamas et al., Real-time vision-based system for textile fabric inspection. Real-Time Imaging 7(6), 507–518 (2001)

A.R. Rao, Future directions in industrial machine vision: a case study of semiconductor manufacturing applications. Image Vis. Comput. 14(1), 3–19 (1996)

N.K. Park, S.I. Yoo, Evaluation of TFT-LCD defects based on human visual perception. Displays 30(1), 1–16 (2009)

A.H. Kashani, C.L. Chen, J.K. Gahm et al., Optical coherence tomography angiography: a comprehensive review of current methods and clinical applications. Prog. Retin. Eye Res. 60, 66–100 (2017)

Y. Jia, S.T. Bailey, D.J. Wilson et al., Quantitative optical coherence tomography angiography of choroidal neovascularization in age-related macular degeneration. Ophthalmology 121(7), 1435–44 (2014)

S. Schuh, J. Holmes, M. Ulrich et al., Imaging blood vessel morphology in skin: dynamic optical coherence tomography as a novel potential diagnostic tool in dermatology. Dermatol. Ther. 7(2), 187–202 (2017)

M. Ulrich, L. Themstrup, N. De Carvalho et al., Dynamic optical coherence tomography in dermatology. Dermatology 232(3), 298–311 (2016)

A.A. Hussain, L. Themstrup, G.B. Jemec, Optical coherence tomography in the diagnosis of basal cell carcinoma. Arch. Dermatol. Res. 307(1), 1–10 (2015)

H. Schneider, K.-J. Park, M. Häfer et al., Dental applications of optical coherence tomography (OCT) in cariology. Appl. Sci. 7(5), 472 (2017)

M. Machoy, J. Seeliger, L. Szyszka-Sommerfeld et al., The use of optical coherence tomography in dental diagnostics: a state-of-the-art review. J. Healthcare. Eng. 2017, 7560645 (2017)

R. Dsouza, H. Subhash, K. Neuhaus et al., Assessment of curing behavior of light-activated dental composites using intensity correlation based multiple reference optical coherence tomography. Lasers Surg. Med. 48(1), 77–82 (2016)

H. Nakagawa, A. Sadr, Y. Shimada et al., Validation of swept source optical coherence tomography (SS-OCT) for the diagnosis of smooth surface caries in vitro. J. Dent. 41(1), 80–9 (2013)

M. Schmoeller, M. Neureiter, C. Stadter et al., Numerical weld pool simulation for the accuracy improvement of inline weld depth measurement based on optical coherence tomography. J. Laser Appl. 32(2), 022036 (2020)

K. Kim, P. Kim, J. Lee et al., Non-destructive identification of weld-boundary and porosity formation during laser transmission welding by using optical coherence tomography. IEEE Access 6, 76768–76775 (2018))

S. Lawman, B. Williams, J. Zhang et al., Scan-less line field optical coherence tomography, with automatic image segmentation, as a measurement tool for automotive coatings. Appl. Sci. 7(4), 351 (2017)

Y. Dong, S. Lawman, Y. Zheng et al., Nondestructive analysis of automotive paints with spectral domain optical coherence tomography. Appl. Opt. 55(13), 3695–3700 (2016)

I. Zorin, R. Su, A. Prylepa et al., Mid-infrared Fourier-domain optical coherence tomography with a pyroelectric linear array. Opt. Express 26(25), 33428–33439 (2018)

P. Ekberg, R. Su, E.W. Chang et al., Fast and accurate metrology of multi-layered ceramic materials by an automated boundary detection algorithm developed for optical coherence tomography data. J. Opt. Soc. Am. A Opt. Image Sci. Vis. 31(2), 217–26 (2014)

M.F. Shirazi, R.E. Wijesinghe, N.K. Ravichandran et al., Quality assessment of the optical thin films using line field spectral domain optical coherence tomography. Opt. Lasers Eng. 110, 47–53 (2018)

R.E. Wijesinghe, K. Park, Y. Jung et al., Industrial resin inspection for display production using automated fluid-inspection based on multimodal optical detection techniques. Opt. Lasers Eng. 96, 75–82 (2017)

M.F. Shirazi, K. Park, R.E. Wijesinghe et al., Fast industrial inspection of optical thin film using optical coherence tomography. Sensors (Basel) 16(10), 1598 (2016)

N.H. Cho, K. Park, J.-Y. Kim et al., Quantitative assessment of touch-screen panel by nondestructive inspection with three-dimensional real-time display optical coherence tomography. Opt. Lasers Eng. 68, 50–57 (2015)

S.H. Park, T.W. Kim, J.H. Lee et al., Real-time critical dimension measurement of thin film transistor liquid crystal display patterns using optical coherence tomography. J. Electron. Image 23(1), 013001 (2014)

M.T. Tsai, F.Y. Chang, Y.J. Lee et al., Defect detection and property evaluation of indium tin oxide conducting glass using optical coherence tomography. Opt. Express 19(8), 7559–7566 (2011)

S.-H. Kim, J.-H. Kim, S.-W. Kang, Nondestructive defect inspection for LCDs using optical coherence tomography. Displays 32(5), 325–329 (2011)

D. Alves-Lima, J. Song, X. Li et al., Review of terahertz pulsed imaging for pharmaceutical film coating analysis. Sensors (Basel) 20(5), 1441 (2020)

Z. Zhang, B. Williams, Y. Zheng et al., Differentiating generic versus branded pharmaceutical tablets using ultra-high-resolution optical coherence tomography. Coatings 9(5), 326 (2019)

M. Wolfgang, A. Peter, P. Wahl et al., At-line validation of optical coherence tomography as in-line/at-line coating thickness measurement method. Int. J. Pharm. 572, 118766 (2019)

Acknowledgements

This work was partially supported by the National Natural Science Foundation of China (61875131); Shenzhen International Cooperation Project (GJHZ20180928161811821) and Shenzhen Basic Research Project (JCYJ20180305125549234).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yang, Z., Gu, Z., Liu, B. et al. Nondestructive in situ detection of microbubble defects in the screen by optical coherence tomography. Eur. Phys. J. Spec. Top. 231, 613–620 (2022). https://doi.org/10.1140/epjs/s11734-021-00384-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1140/epjs/s11734-021-00384-7