Abstract

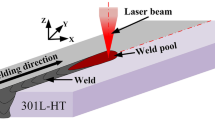

This paper presents a three-dimensional finite element model (FEM) of laser transmission welding of dissimilar plastics. Welding of polycarbonate to ABS (acrylonitrile butadiene styrene) with a moving volumetric heat source is modeled using ANSYS® Parametric Design Language. In model development, consideration is given to all major thermal phenomena associated with the laser transmission welding process, such as heat conduction, convection, and thermal radiation. The model also incorporates the effects of dilution on temperature cycles. Welding experiments are conducted to validate the numerical model. The model predicted simulation results are in good agreement with the measurements. The results predicted by the model can further be used for the optimization of the process.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available in the manuscript. Missing data, if any, that support the findings of this study, are available from the corresponding author upon reasonable request.

Code availability

Software application (ANSYS®) and developed subroutine in APDL (ANSYS® Parametric Design Language).

References

Baylis B, Huang YP, D. Watt (2002) Welding thermoplastic elastomers to polypropylene with a diode laser. Proc. of the 21st International Congress on Applications of Lasers & Electro-Optics, Scottsdale, 171828.

Acherjee B, Kuar AS, Mitra S, Misra D (2012) Experimental investigation on laser transmission welding of PMMA to ABS via response surface modeling. Opt Laser Technol 44 (5:1372–1383

Coelho JMP, Abreu MA, Pires MC (2000) High-speed laser welding of plastic films. Opt Lasers Eng 34:385–395

Bachmann FG, Russek UA (2002) Laser welding of polymers using high power diode lasers. Proc SPIE 4637:505–518

Acherjee B, Kuar AS, Mitra S, Misra D (2013) Finite element simulation of laser transmission thermoplastic welding of circular contour using a moving heat source. Int J Mechatronics Manuf Syst 6(5/6):437–454

Prabhakaran R, Kontopoulou M, Zak G, Bates PJ, Baylis BK (2006) Contour laser – laser-transmission welding of glass reinforced nylon 6. J Thermoplast Compos Mater 19:427–439

Acherjee B (2017) Selection of optimal parameters for laser transmission welding of polycarbonate using desirability function analysis. Mater Today Proc 4:7161–7170

Shin HM, Choi HW (2014) Design of energy optimization for laser polymer joining process. Int J Adv Manuf Technol 75:1569–1576

Acherjee B, Kuar AS, Mitra S, Misra D (2015) Laser transmission welding of polycarbonates: experiments, modeling, and sensitivity analysis. Int J Adv Manuf Technol 78:853–861

Becker F, Potente H (2002) A step towards understanding the heating phase of laser transmission welding in polymers. Polym Eng Sci 42(2):365–374

Kurosaki Y, Matayoshi T (2004) Study of controllability of melt depth in infrared laser penetration welding of thermoplastics. Proc. of Annual Technical Conference – ANTEC 2004, Chicago :1222-1226.

Russek UA, Aden M, Poehler J, Palmen A, Staub H (2004) Laser beam welding of thermoplastics parameter influence on weld seam quality - experiments and modeling. Proc. of the 23rd International Congress on Applications of Lasers & Electro-Optics, San Francisco..

Mayboudi LS, Birk AM, Zak G, Bates PJ (2005) A 2-d thermal model for laser transmission welding of thermoplastics. Proc. of the 24th International Congress on Applications of Lasers & Electro-Optics, Miami : 402-409.

Huang Y, Yu A, Watt D, Baylis B (2006) A numerical study of scanning through-transmission laser welding. Proceedings of Annual Technical Conference – ANTEC 2006, Charlotte, North Carolina, USA :2310-2314.

Van de Ven JD, Erdman AG (2007) Laser transmission welding of thermoplastics — Part I: Temperature and pressure modeling. J Manuf Sci Eng 129:849–858

Mahmood T, Mian A, Amin MR, Auner G, Witte R, Herfurth H, Newaz G (2007) Finite element modeling of transmission laser microjoining process. J Mater Process Technol 186:37–44

Mayboudi LS, Birk AM, Zak G, Bates PJ (2007) A 3-D Thermal model for spot laser transmission welding of thermoplastics. Weld World 51:74–78

Mayboudi LS, Birk AM, Zak G, Bates PJ (2009) A three-dimensional thermal finite element model of laser transmission welding for lap-joint. Int J Model Simul 29(2):149–155

Ilie M, Cicala E, Grevey D, Mattei S, Stoica V (2009) Diode laser welding of ABS: Experiments and process modeling. Opt Laser Technol 41(5):608–614

Hadriche I, Ghorbel E, Masmoudi N, Casalino G (2010) Investigation on the effects of laser power and scanning speed on polypropylene diode transmission welds. Int J Adv Manuf Technol 50:217–226

Acherjee B, Kuar AS, Mitra S, Misra D (2010) Finite element simulation of laser transmission welding of dissimilar materials between polyvinylidene fluoride and titanium. Int J Eng Sci Technol 2(4):176–186

Acherjee B, Kuar AS, Mitra S, Misra D (2012) Modeling and analysis of simultaneous laser transmission welding of polycarbonates using an FEM and RSM combined approach. Opt Laser Technol 44(4):995–1006

Wang X, Chen H, Liu H, Li P, Yan Z, Huang C, Zhao Z, Gu Y (2013) Simulation and optimization of continuous laser transmission welding between PET and titanium through FEM, RSM, GA and experiments. Opt Lasers Eng 51:1245–1254

Wang X, Chen H, Liu H (2014) Investigation of the relationships of process parameters, molten pool geometry and shear strength in laser transmission welding of polyethylene terephthalate and polypropylene. Mater Des 55:343–352

Sooriyapiragasam SK (2016) C Hopmann, Modeling of the heating process during the laser transmission welding of thermoplastics and calculation of the resulting stress distribution. Weld World 60:777–791

Dauphin M, Cosson B (2016) Modeling of thermoplastic composites laser welding - a ray tracing method associated to thermal simulation, AIP Conference Proceedings 1769:020010.

Hopmann C, Kreimeier S (2016) Modelling the heating process in simultaneous laser transmission welding of semicrystalline polymers. J Polym 2016:3824065 10 pages

Aden M (2016) Influence of the laser-beam distribution on the seam dimensions for laser-transmission welding: a simulative approach. Lasers Manuf Mater Process 3(2):100–110

Liu H, Liu W, Meng D, Wang X (2016) Simulation and experimental study of laser transmission welding considering the influence of interfacial contact status. Mater Des 92:246–260

Chen Z, Huang Y, Han F, Tang D (2018) Numerical and experimental investigation on laser transmission welding of fiberglass-doped PP and ABS. J Manuf Process 31:1–8

Lakemeyer P, Schöppner V (2019) Simulation-based investigation on the temperature influence in laser transmission welding of thermoplastics. Weld World 63(2):221–228

ANSYS® Academic Research, Release 10.0, Element Reference. Southpointe: ANSYS, Inc.

Mamuschkin V, Engelmann C, Olowinsky A (2016) Improvement of energy deposition in absorber-free laser welding through quasi-simultaneous irradiation. Phys Procedia 83:472–482

Casalino G, Ghorbel E (2008) Numerical model of CO2 laser welding of thermoplastic polymers. J Mater Process Technol 207:63–71

Ranjbarnodeh E, Serajzadeh S, Kokabi AH, Fischer A (2012) Prediction of temperature distribution in dissimilar arc welding of stainless steel to carbon steel. Proc. IMechE B J Eng Manuf 226(1):117–125

ANSYS® Academic Research, Release 10.0, Command Reference. Southpointe: ANSYS, Inc.

MatWeb® Material Properties data. http://www.matweb.com. Accessed 2019

Z. Tadmor, Thermo-physical properties of polycarbonate, Ph.D. thesis (1979).

CAMPUS® - a material information system for the plastics industry, https://www.campusplastics.com. Accessed 2019

Spekaa M, Mattei S, Pilloza M, Iliea M (2008) The infrared thermography control of the laser welding of amorphous polymers. NDT&E Inter 41:178–183

Li ZZ, Heo KS, Xuan DJ, Seol SY (2009) A study on cooling efficiency using 1-d analysis code suitable for cooling system of thermoforming. J Mech Sci Technol 23:607–613

Acherjee B, Kuar AS, Mitra S, Misra D (2015) Empirical modeling and multi-response optimization of laser transmission welding of polycarbonate to ABS. Lasers Manuf Mater Process 2:103–131

Author information

Authors and Affiliations

Contributions

Sole authorship.

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XVI - Polymer Joining and Adhesive Technology

Rights and permissions

About this article

Cite this article

Acherjee, B. Laser transmission welding of dissimilar plastics: 3-D FE modeling and experimental validation. Weld World 65, 1429–1440 (2021). https://doi.org/10.1007/s40194-021-01079-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01079-2