Abstract

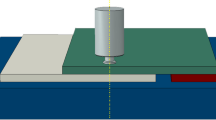

In this research, newly modified solid-state friction-stir welding (FSW) technology was employed to bond the sheets of an aluminum-magnesium alloy (AA5058) and poly-methyl-methacrylate (PMMA) in a lap-joint design. Effects of processing parameters including tool rotational speed (w), traverse velocity (v), tilt angle and plunge depth on the surface morphology, materials flow pattern, microstructural characteristics, and mechanical properties of the dissimilar FSWed joints were studied. The geometry of U-antler macro-mechanical interlocking and interfacial micro- and nano-scale chemical bonding was mainly controlled by the tool tilting angle. A sound dissimilar weld with the highest tensile strength of around 45 MPa was attained at an optimum working window containing w = 1600 rpm, v = 25 mm/min, tool tilt angle of 2°, and plunge depth of 0.2 mm. Fracture of dissimilar lap joints occurred during transverse tensile-shear testing from the weld-polymer interface with a maximum strength ratio of ~ 60% by detachment of aluminum U-antler from the solidified polymer.

Similar content being viewed by others

References

Bozkurt Y (2012) The optimization of friction stir welding process parameters to achieve maximum tensile strength in polyethylene sheets. Mater Des 35:440–445

Oliveira PHF, Amancio-Filho ST, dos Santos JF, Hage E Jr (2010) Preliminary study on the feasibility of friction spot welding in PMMA. Mater Lett 64:2098–2101

Amancio-Filho ST, Bueno C, dos Santos JF, Huber N, Hage E Jr (2011) On the feasibility of friction spot joining in magnesium/fiber-reinforced polymer composite hybrid structures. Mater Sci Eng A 528:3841–3848

Derazkola HA, Aval HJ, Elyasi M (2015) Analysis of process parameters effects on dissimilar friction stir welding of AA1100 and A441 AISI steel. Sci Technol Weld Join 20:553–562

Amancio-Filho ST, dos Santos JF (2009) Joining of polymers and polymer–metal hybrid structures: recent developments and trends. Polym Eng Sci 49:1461–1476

Bilici MK, Yükler Aİ, Kurtulmuş M (2011) The optimization of welding parameters for friction stir spot welding of high density polyethylene sheets. Mater Des 32:4074–4079

Matheny MP, Graff KF (2015) Ultrasonic welding of metals. In: Gallego-Juárez JA, Graff KF (eds) Power ultrasonics. Woodhead Publishing, Oxford, pp 259–293

Yan P, Güngör ÖE, Thibaux P, Liebeherr M, Bhadeshia HKDH (2011) Tackling the toughness of steel pipes produced by high frequency induction welding and heat-treatment. Mater Sci Eng A 528:8492–8499

Abibe AB, Amancio-Filho ST, dos Santos JF, Hage E Jr (2013) Mechanical and failure behaviour of hybrid polymer–metal staked joints. Mater Des 46:338–347

Blaga L, Bancilă R, dos Santos JF, Amancio-Filho ST (2013) Friction Riveting of glass–fibre-reinforced polyetherimide composite and titanium grade 2 hybrid joints. Mater Des 50:825–829

Balle F, Wagner G, Eifler D (2007) Ultrasonic spot welding of aluminum sheet/carbon fiber reinforced polymer – joints. Mater Werkst 38:934–938

Balle F, Wagner G, Eifler D (2009) Ultrasonic metal welding of aluminium sheets to carbon fibre reinforced thermoplastic composites. Adv Eng Mater 11:35–39

Balle F, Eifler D (2012) Statistical test planning for ultrasonic welding of dissimilar materials using the example of aluminum-carbon fiber reinforced polymers (CFRP) joints Statistische Versuchsplanung zum Ultraschallschweißen artfremder Werkstoffe am Beispiel von Aluminium-Kohlefaser-Kunststoff-Verbunden (CFK). Mater Werkst 43:286–292

Goushegir SM, dos Santos JF, Amancio-Filho ST (2014) Friction spot joining of aluminum AA2024/carbon-fiber reinforced poly(phenylene sulfide) composite single lap joints: microstructure and mechanical performance. Mater Des 54:196–206

Goushegir SM, dos Santos JF, Amancio-Filho ST (2015) Influence of process parameters on mechanical performance and bonding area of AA2024/carbon-fiber-reinforced poly(phenylene sulfide) friction spot single lap joints. Mater Des 83:431–442

Bergmann JP, Stambke M (2012) Potential of laser-manufactured polymer-metal hybrid joints. Phys Procedia 39:84–91

Mitschang P, Velthuis R, Didi M (2013) Induction spot welding of metal/CFRPC hybrid joints. Adv Eng Mater 15:804–813

Khodabakhshi F, Haghshenas M, Sahraeinejad S, Chen J, Shalchi B, Li J, Gerlich AP (2014) Microstructure-property characterization of a friction-stir welded joint between AA5059 aluminum alloy and high density polyethylene. Mater Charact 98:73–82

Eslami S, Ramos T, Tavares PJ, Moreira PMGP (2015) Effect of friction stir welding parameters with newly developed tool for lap joint of dissimilar polymers. Procedia Eng 114:199–207

Min J, Li Y, Li J, Carlson BE, Lin J (2014) Friction stir blind riveting of carbon fiber-reinforced polymer composite and aluminum alloy sheets. Int J Adv Manuf Technol 76:1403–1410

Shahmiri H, Movahedi M, Kokabi AH (2017) Friction stir lap joining of aluminium alloy to polypropylene sheets. Sci Technol Weld Join 22:120–126

Khodabakhshi F, Ghasemi Yazdabadi H, Kokabi AH, Simchi A (2013) Friction stir welding of a P/M Al–Al2O3 nanocomposite: microstructure and mechanical properties. Mater Sci Eng A 585:222–232

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R Rep 50:1–78

Khodabakhshi F, Simchi A, Kokabi A (2017) Surface modifications of an aluminum-magnesium alloy through reactive stir friction processing with titanium oxide nanoparticles for enhanced sliding wear resistance. Surf Coat Technol 309:114–123

Nandan R, DebRoy T, Bhadeshia HKDH (2008) Recent advances in friction-stir welding—process, weldment structure and properties. Prog Mater Sci 53:980–1023

Ma ZY (2008) Friction stir processing technology: a review. Metall Mater Trans A 39:642–658

Yusof F, Miyashita Y, Seo N, Mutoh Y, Moshwan R (2012) Utilising friction spot joining for dissimilar joint between aluminium alloy (A5052) and polyethylene terephthalate. Sci Technol Weld Join 17:544–549

Goushegir SM, dos Santos JF, Amancio-Filho ST (2014) Friction spot joining of aluminum AA2024/carbon-fiber reinforced poly(phenylene sulfide) composite single lap joints: microstructure and mechanical performance. Mater Des (1980-2015) 54:196–206

Khodabakhshi F, Haghshenas M, Chen J, Shalchi Amirkhiz B, Li J, Gerlich A (2017) Bonding mechanism and interface characterisation during dissimilar friction stir welding of an aluminium/polymer bi-material joint. Sci Technol Weld Join 22:182–190

Liu FC, Nakata K, Liao J, Hirota S, Fukui H (2014) Reducing bubbles in friction lap welded joint of magnesium alloy and polyamide. Sci Technol Weld Join 19:578–587

Ratanathavorn W, Melander A (2015) Dissimilar joining between aluminium alloy (AA 6111) and thermoplastics using friction stir welding. Sci Technol Weld Join 20:222–228

Derazkola HA, Khodabakhshi F, Simchi A (2017) Friction-stir lap-joining of aluminium-magnesium/poly-methyl-methacrylate hybrid structures: thermo-mechanical modelling and experimental feasibility study. Sci Technol Weld Join. https://doi.org/10.1080/13621718.2017.1323441

AK P, Raj R, Kailas SV (2015) A novel in-situ polymer derived nano ceramic MMC by friction stir processing. Mater Des 85:626–634

Simões F, Rodrigues DM (2014) Material flow and thermo-mechanical conditions during friction stir welding of polymers: literature review, experimental results and empirical analysis. Mater Des 59:344–351

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP (2015) Friction stir processing of an aluminum-magnesium alloy with pre-placing elemental titanium powder: in-situ formation of an Al3Ti-reinforced nanocomposite and materials characterization. Mater Charact 108:102–114

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP (2016) Similar and dissimilar friction-stir welding of an PM aluminum-matrix hybrid nanocomposite and commercial pure aluminum: microstructure and mechanical properties. Mater Sci Eng A 666:225–237

Khodabakhshi F, Simchi A, Kokabi A, Gerlich A, Nosko M, Švec P (2017) Influence of hard inclusions on microstructural characteristics and textural components during dissimilar friction-stir welding of an PM Al–Al2O3–SiC hybrid nanocomposite with AA1050 alloy. Sci Technol Weld Join 22:412–427

Mendes N, Neto P, Loureiro A, Moreira AP (2016) Machines and control systems for friction stir welding: a review. Mater Des 90:256–265

Abibe AB, Sônego M, dos Santos JF, Canto LB, Amancio-Filho ST (2016) On the feasibility of a friction-based staking joining method for polymer–metal hybrid structures. Mater Des 92:632–642

Vigueras DJ, de Renero CT, Inal OT (2007) Explosive and impact welding: technical review. Mater Technol 22:200–204

Simar A, Bréchet Y, de Meester B, Denquin A, Gallais C, Pardoen T (2012) Integrated modeling of friction stir welding of 6xxx series Al alloys: process, microstructure and properties. Prog Mater Sci 57:95–183

Author information

Authors and Affiliations

Corresponding authors

Additional information

Recommended for publication by Commission XVI - Polymer Joining and Adhesive Technology

Rights and permissions

About this article

Cite this article

Derazkola, H.A., Kashiry Fard, R. & Khodabakhshi, F. Effects of processing parameters on the characteristics of dissimilar friction-stir-welded joints between AA5058 aluminum alloy and PMMA polymer. Weld World 62, 117–130 (2018). https://doi.org/10.1007/s40194-017-0517-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-017-0517-y