Abstract

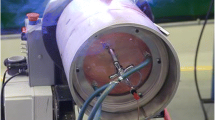

The influence of welding position on properties of duplex and superduplex stainless steel welds was studied. Circumferential pipe welds were produced using mechanised gas metal arc welding in flat position, vertical up position and overhead position. Dilution, corrosion resistance, mechanical properties, microstructural features and weld imperfections were assessed and related to the welding position. Welds produced in flat and vertical up positions were less likely to produce porosity than those welded in overhead position, whilst underfill was not observed in overhead position welds. All the duplex pipe welds passed the corrosion test regardless of the welding position and showed sound microstructures. Under fixed arc energy conditions, welds produced in vertical up position showed the lowest dilution values whilst welds in flat position showed the highest. Excellent impact toughness values and cross tensile values were found regardless of the welding positions. Whenever possible, flat position is recommended as welds showed less proneness to porosity. Vertical up position is recommended as the second best choice.

Similar content being viewed by others

References

International Molybdenum Association (IMOA) (2011) The use of 2205 duplex stainless steel for pharmaceutical and biotechnology applications. ISBN 978-1-907470-25-7. 8 pages

Karlsson L (2012) Welding duplex stainless steels—a current review of recommendations. Welding in the World 56:65–76

Guimaraes de Vasconcellos PI, Rosenthal R, Rocha Paranhos RP (2010) Study of the welding of duplex and superduplex stainless steel pipes in the 5G position. Soldagem & Inspeção 15(3):191–199

Kim H-J, Jeon S-H, Kim S-T, Lee I-S, Park Y-S, Kim K-T, Kim Y-S (2014) Investigation of the sensitization and intergranular corrosion of tube-to-tubesheet welds of hyper duplex stainless steel using an electrochemical reactivation method. Corrosion Science 87:60–70

Smith JO, Mueller SM, Volpone LM (2007) Weldability of an austenitic-ferritic 1.4462 (SAF 2205) steel on tubular products using GTAW in keyhole-modality (K-TIG). Duplex 2007 International Conference & Expo, hold in Grado (Italy), 18-20 June, 12 pages

EN ISO 6947:2011 (2011). Welding and allied processes. Welding positions

Pettersson C-O, Fager S-Å (1995) Welding practice for the Sandvik duplex stainless steels SAF 2304, SAF 2205 and SAF 2507. AB Sandvik Steel. Technical document S-91-57, April 1994, revised August 1995. 15 pages

How to weld duplex stainless steels (2006) Avesta Welding AB. Document 10601EN-GB, 20 pages. Avesta, Sweden

Welding guidelines for duplex & superduplex stainless steels (2005) Metrode Products Limited. February 2005, 7 pages. Chertsey, UK

Persson K-A (2014) Pore formation in MIG welding duplex stainless steels with super duplex filler wire. Conference “Svetsning av rostfria stål” organised by Swerea/Kimab. Stockholm, 4th June 2014

Valiente Bermejo MA, Karlsson L, Svensson L-E, Hurtig K, Rasmuson H, Frodig M, Bengtsson P (2014) Effect of shielding gas on welding performance and properties of duplex and superduplex stainless steel welds. Welding in the World. doi: 10.1007/s40194-014-0199-7, published on-line on the 29th October 2014

van Nassau L, Meelker H, Hilkes J (1993) Welding duplex and super-duplex stainless steels. Welding in the World 31(5):322–343

Welding consumables technical handbook (2009). Metrode Products Limited. Revision 10, August 2009, 384 pages. Chertsey, UK

EN 10028: 2008 (2008). Flat products made of steels for pressure purposes, part 7: stainless steels

NORSOK STANDARD M-601 (2008). Welding and inspection of piping

Acknowledgments

The Knowledge Foundation is gratefully acknowledged for the economic funding. The great support received from the business partners involved AGA Gas AB, ESAB AB and Sandvik Materials Technology, and the involvement and contribution of their representatives are also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Doc. IIW-2557, recommended for publication by Commission IX “Behaviour of Metals Subjected to Welding”.

Rights and permissions

About this article

Cite this article

Valiente Bermejo, M., Karlsson, L., Svensson, LE. et al. Effect of welding position on properties of duplex and superduplex stainless steel circumferential welds. Weld World 59, 693–703 (2015). https://doi.org/10.1007/s40194-015-0245-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-015-0245-0