Abstract

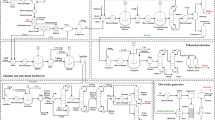

A techno-economic and environmental analysis for the production of biodiesel, ethanol, butanol, hydrogen and electricity as main products and acetone as by-product from oil palm was studied considering the biorefinery concept in the Colombian context. Fresh fruit bunches were used as raw material to obtain biofuels and bioenergy. As a result, the production costs under the biorefinery concept are 0.34, 9.59, 5.69, 6.98 and 5.69 USD per kilogram of biodiesel, hydrogen, butanol, ethanol and acetone, respectively. Besides, the cost related to the electricity generation is 0.7 USD per kWh. According to these results, biodiesel and hydrogen, have a positive economic margin of 77 and 20 %, respectively. On the other hand, the biorefinery presents a negative economic margin for both minimum and maximum sale prices of the products due to the low productivity of most of the process stages. As a consequence, the process scale is the key parameter in the economic profitability for this biorefinery. From the environmental point of view, the stages involved in the biodiesel production have a lesser extent of potential environmental impact in the biorefinery due to the minimum waste streams generated.

Similar content being viewed by others

References

Aristizábal M, V., Gómez, P.A., Cardona A, C.A.: Biorefineries based on coffee cut-stems and sugarcane bagasse: Furan-based compounds and alkanes as interesting products. Bioresour. Technol. 196, 480–489 (2015)

Warner, E., Zhang, Y., Inman, D., Heath, G., Renewable, N.: Challenges in the estimation of greenhouse gas emissions from biofuel-induced global land-use change. Bioprod. biorefining, Biofuels (2013)

Luque, R., Herrero-Davila, L., Campelo, J.M., Clark, J.H., Hidalgo, J.M., Luna, D., Marinas, J.M., Romero, A.A.: Biofuels: a technological perspective. Energy Environ. Sci. 1(5), 542 (2008)

Rincón, L.E., Hernández, V., Cardona, C.A.: Analysis of technological schemes for the efficient production of added-value products from Colombian oleochemical feedstocks. Process Biochem. 49, 474–489 (2014)

Balan, V.: Review of US and EU initiatives toward development, demonstration, and commercialization of lignocellulosic biofuels. Biofuels, Bioprod. Biorefining 7, 732–759 (2013)

Rincón, L.E., Moncada, J., Cardona, C.A.: Analysis of potential technological schemes for the development of oil palm industry in Colombia: a biorefinery point of view. Ind. Crops Prod. 52, 457–465 (2014)

Clark, J.H., Luque, R., Matharu, A.S.: Green chemistry, biofuels, and biorefinery. Annu. Rev. Chem. Biomol. Eng. 3, 183–207 (2012)

Cherubini, F.: The biorefinery concept: using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 51, 1412–1421 (2010)

Cherubini, F., Wellisch, M., Willke, T.: Toward a common classifi cation approach for biorefi nery systems. Bioprod. biorefining, Biofuels (2009)

Rocha Ortega, S., Vesga Pinto, J. N.: Extracción exergética del proceso de extracción de aceite de la palma africana. Universidad Industrial de Santander, 2011

Morales-Rodriguez, R., Gernaey, K.V., Meyer, A.S., Sin, G.: A Mathematical model for simultaneous saccharification and co-fermentation (SSCF) of C6 and C5 sugars. Chin. J. Chem. Eng. 19, 185–191 (2011)

Gadhamshetty, V., Arudchelvam, Y., Nirmalakhandan, N., Johnson, D.C.: Modeling dark fermentation for biohydrogen production: ADM1-based model versus Gompertz model. Int. J. Hydrogen Energy 35, 479–490 (2010)

Biswas, P., Agrawal, S., Sinha, S.: Modeling and simulation for pressure swing adsorption system for hydrogen purification. Chem. Biochem. Eng. Q. 24, 409–414 (2010)

van der Merwe, A.B.: Evaluation of different process designs for biobutanol production from sugarcane molasses. University of Stellenbosch (2010)

Balat, M., Balat, M., Kırtay, E., Balat, H.: Main routes for the thermo-conversion of biomass into fuels and chemicals. Part 2: gasification systems. Energy Convers. Manag. 50, 3158–3168 (2009)

Rincón, L.E., Becerra, L.A., Moncada, J., Cardona, C.A.: Techno-economic analysis of the use of fired cogeneration systems based on sugarcane bagasse in south eastern and mid-western regions of Mexico. Waste Biomass Valorization 5, 189–198 (2013)

Ahmed, I.I., Gupta, A.K.: Sugarcane bagasse gasification: global reaction mechanism of syngas evolution. Appl. Energy 91, 75–81 (2012)

Xu, Y., Ye, T., Qiu, S., Ning, S., Gong, F., Liu, Y., Li, Q.: High efficient conversion of CO2-rich bio-syngas to CO-rich bio-syngas using biomass char: a useful approach for production of bio-methanol from bio-oil. Bioresour. Technol. 102, 6239–6245 (2011)

Adapa, P., Tabil, L., Schoenau, G.: Grinding performance and physical properties of non-treated and steam exploded barley, canola, oat and wheat straw. Biomass Bioenergy 35, 549–561 (2011)

Najjar, Y.S.: Gas turbine cogeneration systems: a review of some novel cycles. Appl. Therm. Eng. 20, 179–197 (2000)

Granjo, José F.O., Duarte, Belmiro P.D., Oliveira, Nuno M.C.: Kinetic models for the homogeneous alkaline and acid catalysis in biodiesel production. Comput. Aided Chem. Eng. 27(2009), 483–488 (2009)

Fangrui Ma, M.A.H., Davis Clements, L.: Biodiesel fuel from animal fat. Ancillary studies on transesterification of beef tallow. Ind. Eng. Chem. Res. 37(9), 3768–3771 (1998)

Chaudhary, N., Ngadi, M.O., Simpson, B.K., Kassama, L.S.: Biosynthesis of ethanol and hydrogen by glycerol fermentation using Escherichia coli. Adv. Chem. Eng. Sci. 1, 83–89 (2011)

Pitt, W.W., Haag, G.L., Lee, D.D.: Recovery of ethanol from fermentation broths using selective sorption–desorption. Biotechnol. Bioeng. 25, 123–131 (1983)

Young, D.M., Cabezas, H.: Designing sustainable processes with simulation: the waste reduction (WAR) algorithm. Comput. Chem. Eng. 23, 1477–1491 (1999)

Noomtim, P., Cheirsilp, B.: Production of butanol from palm empty fruit bunches hydrolyzate by clostridium acetobutylicum. Energy Procedia 9, 140–146 (2011)

Chong, P.S., Jahim, J.M., Harun, S., Lim, S.S., Mutalib, S.A., Hassan, O., Nor, M.T.M.: Enhancement of batch biohydrogen production from prehydrolysate of acid treated oil palm empty fruit bunch. Int. J. Hydrogen Energy 38, 9592–9599 (2013)

Rincón, L.E., Valencia, M.J., Hernández, V., Matallana, L.G., Cardona, C.A.: Optimization of the Colombian biodiesel supply chain from oil palm crop based on techno-economical and environmental criteria. Energy Econ. 47, 154–167 (2015)

Posada, J.A., Rincón, L.E., Cardona, C.A.: Design and analysis of biorefineries based on raw glycerol: addressing the glycerol problem. Bioresour. Technol. 111, 282–293 (2012)

ALIBABA 2014 International Prices. www.alibaba.com

ICIS Chemical Pricing. Price reports for chemicals. http://www.icis.com/chemicals/channel-info-chemicals-a-z/ (2010)

FEDEBIOCOMBUSTIBLES: Biofuel prices in Colombia. http://www.fedebiocombustibles.com/v3/estadistica-precios-titulo-Alcohol_Carburante_(Etanol).htm (2014)

NME, N.m.y.E. LyD considers risky the propose of an energetic development based on shale gas. http://www.nuevamineria.com/revista/2013/ (2013)

Botero, J. M.: Design and evaluation of sustainable biorefineries from feedstocks in tropical regions. Master thesis. Departamento de Ingeniería Química, Universidad Nacional de Colombia sede Manizales (2012)

Acknowledgments

The authors express their acknowledgments to the Universidad Nacional de Colombia at Manizales and the research group in Chemical, Catalytic and Biotechnological Processes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aristizábal M, V., García V, C.A. & Cardona A, C.A. Integrated Production of Different Types of Bioenergy from Oil Palm Through Biorefinery Concept. Waste Biomass Valor 7, 737–745 (2016). https://doi.org/10.1007/s12649-016-9564-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9564-7