Abstract

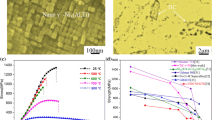

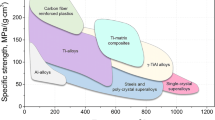

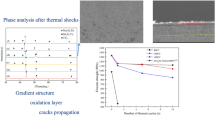

In this paper, a novel type of functionally graded material (FGM) was successfully fabricated from pure Ni and Ti3AlC2 powder mixtures by hot-press sintering route at 1200 °C and 17 MPa. In each layer, Ti3AlC2 particles transformed into TiCx phase, while the additional Al–Ti atoms decomposed from Ti3AlC2 diffused into the Ni matrix, giving rise to the formation of γ′-Ni3(Al,Ti). Part of the submicron TiCx and Ni3(Al,Ti) particles were uniformly distributed in the Ni matrix, while some of the TiCx maintained the original Ti3AlC2 plate-like morphology. Both TiCx and Ni3(Al,Ti) content decreased from 60Ti3AlC2/Ni layer to 10Ti3AlC2/Ni layer in a stepwise manner was fabricated. The microstructural analysis indicates that no cracks, delamination and step-type abrupt changes occured in the graded layer of the manufactured FGM. Flexural strength and Vickers hardness enhanced with the increasing Ti3AlC2 content except for fracture strain and toughness. The overall fracture toughness and the flexural strength of FGM can reach 21.76 MPa m1/2 and 1329 ± 34 MPa, respectively. The prepared FGM, herein, with a hard ceramic surface on one side to resist local plastic deformation, and a ductile metallic surface on the other side to provide toughness.

Graphic Abstract

Similar content being viewed by others

References

K.H. Choi, H.-S. Kim, C.H. Park, Met. Mater. Int. 22, 817 (2016)

W. Woo, D.K. Kim, E.J. Kingstonc, Mater. Sci. Eng., A 744, 618 (2019)

M. Naebe, K. Shirvanimoghaddam, Appl. Mater. Today 5, 223 (2016)

Z.H. Jin, G.H. Paulino, Int. J. Fract. 107, 73 (2001)

W. Pompea, H. Worch, M. Epple, W. Friess, M. Gelinsky, P. Greil, Mater. Sci. Eng., A 362, 40 (2003)

B. Saleh, J. Jiang, A. Ma, Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00273-8

T. Traini, C. Mangano, R.L. Sammons, F. Mangano, A. Macchi, A. Piattelli, Dent. Mater. 24, 1525 (2008)

D. Kim, K. Park, K. Kim, Mater. Sci. Eng., A 745, 379 (2019)

C. Morin, S. Le Gallet, M. Ariane, F. Bernarda, Ceram. Int. 42, 3056 (2016)

T. Fujii, K. Tohgo, M. Iwao, J. Alloys Compd. 766, 1 (2018)

Q. Cong, F.M. Xu, J.Y. Li, J. Mater. Sci. Forum 675, 575 (2011)

M. Eriksson, M. Radwan, Z. Shen, Int. J. Refract. Metals Hard Mater. 36, 31 (2013)

D.M. Hulbert, D. Jiang, D.V. Dudina, A.K. Mukherjee, Int. J. Refract. Metals Hard Mater. 27, 367 (2009)

X.-H. Zhang, J.-C. Han, S.-Y. Du, J.V. Wood, J. Mater. Sci. 35, 1925 (2000)

X. Jin, L. Wu, Y. Sun, Mater. Sci. Eng., A 509, 63 (2009)

K. Tohgo, T. Suzuki, H. Araki, Eng. Fract. Mech. 72, 2359 (2005)

K. Tohgo, M. Iizuka, H. Araki, Y. Shimamura, Eng. Fract. Mech. 75, 4592 (2008)

L. Li, J. Wang, P. Lin, H. Liu, Ceram. Int. 43, 16638 (2017)

J. Pawel, P. Wojciech, B. Zbigniew, Materials 8, 2537 (2015)

Y.C. Ding, S.B. Zhang, J.H. Liu, J. Foundry Technol. 7, 1376 (2014)

Y.F. Yang, D.K. Mu, Q.C. Jiang, Mater. Chem. Phys. 143, 480 (2014)

G. Gobinda, S.H. Cho, S.W. Lee, Met. Mater. Int. 19, 113 (2013)

X.D. Hui, Y.S. Yang, Z.F. Wang, Mater. Sci. Eng., A 282, 187 (2000)

E. Dănăilă, L. Benea, N. Caron, Met. Mater. Int. 22, 924 (2016)

Y. Lyu, Y. Sun, Y. Yang, Met. Mater. Int. 22, 311 (2016)

Y. Chol, J.K. Lee, M.E. Mullins, J. Mater. Sci. 32, 1717 (1997)

Q.S. Song, Q. Xu, L. Xu, J. Alloys Compd. 690, 116 (2017)

Z.D. Liu, J. Tian, B. Li, L.P. Zhao, Mater. Sci. Eng., A 527, 3898 (2010)

J.C. Han, X.H. Zhang, J.V. Wood, Mater. Sci. Eng., A 280, 328 (2000)

M.Y. Koo, J.S. Park, J. Scr, Scr. Mater. 66, 487 (2012)

G.Q. Xiao, Q.C. Fan, M.Z. Guo, Mater. Sci. Eng., A 382, 132 (2004)

B.H. Lohse, A. Calka, D. Wexler, J. Alloys Compd. 394, 148 (2005)

A.W. Weimer, Carbide, J. Eur. Ceram. Soc. 18, 735 (1998)

Y. Choi, S.W. Rhee, J. Mater. Sci. 28, 6669 (1993)

W.J. Wang, H.X. Zhai, L. Chen, Z.Y. Huang, Mater. Sci. Eng., A 616, 214 (2014)

Y.F. Yang, H.Y. Wang, J. Zhang, J. Am. Ceram. Soc. 91, 2736 (2008)

Z.Y. Huang, J. Bonneville, H.X. Zhai, J. Alloys Compd. 602, 53 (2014)

W.Q. Hu, Z.Y. Huang, L.P. Cai, Mater. Sci. Eng., A 697, 48 (2017)

W.Q. Hu, Z.Y. Huang, L.P. Cai, J. Alloys Compd. 747, 1043 (2018)

W.Q. Hu, Z.Y. Huang, L.P. Cai, J. Alloys Compd. 765, 987 (2018)

W.Q. Hu, Z.Y. Huang, G.M. Zheng, J. Alloys Compd. 774, 739 (2019)

M.X. Ai, H.X. Zhai, Y. Zhou, J. Am. Ceram. Soc. 89, 1114 (2006)

W.Q. Hu, Z.Y. Huang, L.P. Cai, Mater. Charter 135, 295 (2018)

K.J. Lee, P. Nash, J. Phase Equil. 12, 551 (1991)

E.O. Ezugwu, Z.M. Wang, A.R. Machado, J. Mater. Process. Technol. 86, 1 (1999)

J.N. DuPont, J.C. Lippold, S.D. Kiser, Welding Metallurgy and Weldability of Nickel-Based Alloys (Wiley, Hoboken, 2009), pp. 26–30

L.C. Hsiung, H.H. Sheu, J. Alloys Compd. 479, 314 (2009)

H.M. Wen, T.D. Topping, D. Isheim, Acta Mater. 61, 2769 (2013)

J.R. Davis, Nickel, cobalt, and their alloys (ASM International, Russell Township, 2000)

Acknowledgements

This work was supported by National Science Foundation of China (NSFC) under Grant Nos. 51871011, 51572017 and 51301013, by Beijing Government Funds for the Constructive Project of Central Universities, and by fundamental Research Funds for the Central Universities under Grant No. 2018YJS144.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, G., Huang, Z., Yu, Q. et al. Microstructural and Mechanical Properties of TiCX–Ni3(Al,Ti)/Ni Functionally Graded Composites Fabricated from Ti3AlC2 and Ni Powders. Met. Mater. Int. 26, 905–913 (2020). https://doi.org/10.1007/s12540-019-00357-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00357-5