Abstract

Compressed air can be used as an energy source for brake systems in medium-heavy and heavy-duty commercial vehicles. The moisture in compressed air, which is due to high temperature and humidity, can be eliminated by using an air dryer. In this paper, drying performance data for a cartridge were obtained and used to develop a drying performance program, to predict the moisture and relative humidity in the air tanks of vehicles. The on-load time, off-load time, air flow, duty cycle, humidity and dew point temperature were calculated according to air consumption. The validity of the program was verified, and it was shown to be able to predict humidity changes in the air tank. The air tank capacity was increased from 100 to 130 to reduce the duty cycle. Therefore, the regeneration rate decreased from 18% to 15%, but the dew point depression temperature (ΔT) remained above 30°C. The duty cycle decreased from 50% to 43%, and the total operation time and power consumption of the air compressor were reduced. In conclusion, fuel savings were obtained by changing the parameters to optimize the system.

Similar content being viewed by others

References

American Standard Test Method (1971). Standard Test Method for Collection Efficiency of High Efficiency Particulate Air Filter. ASTM D-2986-71. West Conshohocken. USA.

Fornof, W. P. (1999). Compressor oil carryover and its effect on the pneumatic system. SAE Paper No. 1999-01-3768.

Fornof, W. P. (2004). A method for determining the efficiency of a coalescing filter. SAE Paper No. 2004-01-2733.

Forsythe, W. E. (2003). Smithsonian Physical Tables. 9th Revised Edn. Knovel. New York.

Hildebrandt, R. W. (1970). The 1970 Ford dual circuit air brake system. SAE Paper No. 700504.

Jung, Y. Y., Kim, K. H., Kim, S. W., Lee, H. J. and Kim, B.S. (2009). A study on the dew condensation control. Annual Conf. Proc., Korean Society of Automotive Engineers, 3014–3017.

Kim, T. H., Kim, E. S., Cho, S. H. and Ahn, J. W. (2010). Humidity control system of GM DAT climatic wind tunnel. Annual Conf. Proc., Korean Society of Automotive Engineers, 1144–1151.

Koo, K. H. (2010). A study on reduction of fuel consumption by displaying fuel injection data for drivers. Trans. Korean Society of Automotive Engineers 18,4, 115–120.

Lee, K. I., Song, B. H., Han, J. P. and Lee, T. W. (2010). Aerodynamic front end styling using the optimized opening for fuel efficiency improvement. Annual Conf. Proc., Korean Society of Automotive Engineers, 344–349.

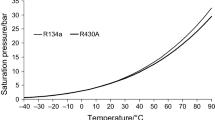

Lee, Y. Y., Park, H. S. and Hwang, Y. K. (2001). Performance analysis of fridge air dryer system using the alternative refrigerants. Summer Conf. Proc., SAREK, 250–255.

SAE (1999). Air Dryer Test Procedure. Ingormation Report. SAE J2384. New York.

Song, Y. H., Jang, W. W., Song, Y. K. and Kim, K. H. (1995). A study of receiver dryer for automotive air-conditioning system. Spring Conf. Proc., KSME, 581–587.

Yoon, B. D., Kim, K. H. and Jang, J. S. (2003). A study on the integral condenser-receiver dryer in automotive air conditioning system. Spring Conf. Proc., Korean Society of Automotive Engineers, 1247–1253.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, W.K., Mun, S.D., Lee, H.K. et al. Optimization of drying performance considering driving conditions. Int.J Automot. Technol. 12, 705–712 (2011). https://doi.org/10.1007/s12239-011-0082-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12239-011-0082-0