Abstract

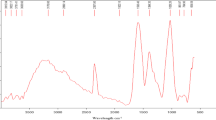

Aqueous extract of Eucalyptus globulus L. bark is used for simultaneous dyeing and finishing of cotton, silk, wool, and eri silk fabrics in the absence of inorganic salts or mordants for producing value-added environment-friendly products. All the fabrics have an affinity towards the colorants obtained from this bark. The phytochemical studies reveal the presence of bioactive compounds, i.e. saponin, phenols, tannin, flavonoids, terpenoids, and glycosides in the bark. The protein fabrics dyed with this extract exhibit improved color fastness to washing and light as compared to cotton. A positive value of both a* and b* indicates the color of all the fabrics dyed with this bark is reddish-yellow. K/S values of all the dyed fabrics are improved with the increase in dye bath concentration from 100 g/l to 200 g/l for all the fabrics dyed with these colorants. The calculated average particle size and zeta potential value of the aqueous extract is ∼535 nm and −22.4 mV, respectively. All the dyed fabrics show an excellent result in terms of resistance against S. aureus and E. coli at 200 g/l dye concentration. Eucalyptus bark at 200 g/l dye bath concentration results in maximum UPF value for cotton, eri silk, and wool fabrics.

Similar content being viewed by others

References

I. Miranda, J. Gominho, and H. Pereira, BioResources, 7, 4350 (2012).

M. G. Vecchio, C. Loganes, and C. Minto, Open Agric. J., 10, 52 (2016).

E. Saadaoui, K. B. Yahia, S. Dhahri, M. L. Ben Jama, and M. L. Khouja, Forestry Studies, 67, 86 (2017).

T. Osawa and M. Namiki, Agric. Biol. Chem., 45, 735 (1981).

D. R. Batish, H. Pal Singh, R. K. Kohli, and S. Kaur, For. Ecol. Manage., 256, 2166 (2008).

T. Takahashi, R. Kokubo, and M. Sakaino, Appl. Microbiol., 39, 60 (2004).

M. A. Lima, G. B. Lavorente, H. K. P. da Silva, J. Bragatto, C. A. Rezende, O. D. Bernardinelli, E. R. deAzevedo, L. D. Gomez, S. J. McQueen-Mason, C. A. Labate, and I. Polikarpov, Biotechnol. Biofuels, 6, 1 (2013).

I. Miranda, J. Gominho, I. Mirra, and H. Pereira, Ind. Crops Prod., 41, 299 (2013).

V. Sarin and K. K. Pant, Bioresour. Technol., 97, 15 (2006).

L. C. Morais, O. M. Freitas, E. P. Goncalves, L. T. Vasconcelos, and C. G. Gonzalez Beca, Water. Res., 33, 979 (1999).

M. Yusuf, A. Ahmad, M. Shahid, M. I. Khan, S. A. Khan, N. Manzoor, and F. Mohammad, J. Cleaner Prod., 27, 42 (2012).

M. Yusuf, M. Shahid, S. A. Khan, M. I. Khan, S. U. Islam, F. Mohammad, and M. A. Khan, J. Nat. Fibers, 10, 14 (2013).

N. Baaka, W. Haddar, M. Ben Ticha, M. T. P. Amorim, and M. F. M’Henni, Nat. Prod. Res., 31, 1655 (2017).

K. Phan, E. Van Den Broeck, V. Van Speybroeck, K. De Clerck, K. Raes, and S. De Meester, Dyes Pigm., 176, 108180 (2020).

M. Yusuf, M. Shabbir, and F. Mohammad, Nat. Prod. Bioprospect., 7, 123 (2017).

B. Gebhardt, R. Sperl, R. Carle, and J. Müller-Maatsch, J. Cleaner Prod., 260, 120884 (2020).

S. Saxena and A. S. M. Raja in “Roadmap to Sustainable Textiles and Clothing” (S. Muthu Ed.), pp.37–80, Textile Science and Clothing Technology, Springer, Singapore, 2014.

S. Jose, P. Pandit, and R. Pandey, Ind. Crops Prod., 142, 111833 (2019).

V. Meena and J. Sheikh, Cellulose Chem. Technol., 52, 883 (2018).

R. Mongkholrattanasit, J. Kryštůfek, J. Wiener, and M. Viková, Fibres Text. East. Eur., 19, 94 (2011).

L. J. Rather, M. Shabbir, Q. Li, and F. Mohammad, AIChE Environ. Prog. Sustainable Energy, 38, 13187 (2019).

K. A. Omer, Z. Tao, and A. I. Seedahmed, Fibres Text. East. Eur., 23, 60 (2015).

S. Han and Y. Yang, Dyes Pigm., 64, 157 (2005).

A. Sharma, S. Kadam, P. Mathur, S. Islam, and J. Sheikh, Sustainable Chem. Pharm., 11, 17 (2019).

E. Koh and K. H. Hong, Dyes Pigm., 103, 222 (2014).

K. H. Prabhu, M. D. Teli, and N. G. Waghmare, Fiber. Polym., 12, 753 (2011).

M. L. Gulrajani, D. Gupta, and S. Ray Maulik, Indian J. Fibre Text. Res., 24, 131 (1999).

M. D. Teli and P. Pandit, ACS Sustainable Chem. Eng., 5, 8323 (2017).

S. Roy Maulik and K. Agarwal, Indian J. Trad. Knowl., 13, 589 (2014).

D. Das, S. Ray Maulik, and S. C. Bhattacharya, Indian J. Fibre Text. Res., 33, 163 (2008).

S. Roy Maulik and L. Chakraborty, Asian Dyer, 15, 60 (2018).

S. Ray Maulik, D. Das, and S. C. Bhattacharya, J. Text. Inst., 102, 491 (2011).

S. Roy Maulik, J. Inst. Eng. (India): Series E, 100, 1 (2019).

ISO 105-C10:2006, “Textiles-Tests for Colorfastness — Part C10: Colorfastness to Washing with Soap or Soap and Soda, Test Condition: Test A (1)”, International Organization for Standardization, Geneva, Switzerland.

IS2454-1984, “Determination of Colorfastness of Textile Materials to Light”, IST Handbook of Textile Testing, 1984.

ISO 105-X12:1993, “Textiles — Tests for Colour Fastness — Part X12: Colour Fastness to Rubbing”, International Organization for Standardization, Geneva, Switzerland, 1993.

L. Chakraborty, P. Pandit, and S. Roy Maulik, J. Cleaner Prod., 245, 118921 (2020).

M. D. Teli and P. Pandit, Fiber. Polym., 18, 1679 (2017).

M. D. Teli and P. Pandit, Fiber. Polym., 19, 41 (2018).

A. Johnson, “The Theory of Colouration of Textiles”, 2nd ed., p.111, Society of Dyers & Colourists, Bradford, West Yorkshire, England, 1989.

C. L. Bird, “Theory and Practice of Wool Dyeing”, Society of Dyers & Colourists, Bradford, England, 1972.

M. L. Gulrajani, “Production of Silk: Chemical Processing of Silk”, Indian Institute of Technology, Delhi, 1993.

T. L. Dawson, J. Soc. Dyers Colour., 97, 115 (1981).

V. Sharma and R. Paliwal, Int. J. Pharm. Pharm. Sci., 5, 179 (2013).

M. A. Maobe and R. M. Nyarango, Global J. Pharmacol., 7, 61 (2013).

M. Arshad, A. Beg, and Z. A. Siddiqui, Macromol. Mater. Eng., 7, 67 (1969).

M. Shahid and F. Mohammad, J. Cleaner Prod., 53, 310 (2013).

M. Gorenšiek, F. Sluga, and R. Urbas, AATCC Review, 7, 44 (2007).

P. S. Vankar, V. Tiwari, and J. Srivastava, Electron. J. Environ. Agric. Food Chem., 5, 1664 (2006).

F. Yaylaci, S. Kolayli, M. Kucuk, S. Alpay Karaoglu, and E. Ulusoy, Asian J. Chem., 19, 2241 (2007).

B. R. Min, R. Merkel, S. Walker, G. Tomita, and R. C. Anderson, Sci. Res. Essays, 3, 66 (2008).

H. Akiyama, K. Fujii, O. Yamasaki, T. Oono, and K. Iwatsuki, J. Antimicrob., 48, 487 (2001).

T. P. T. Cushnie and A. J. Lamb, Int. J. Antimicrob. Agents, 26, 343 (2005).

L. Ammayappan and S. Jose in “Handbook of Sustainable Apparel Production”, 1st ed. (S. S. Muthu Ed.), p.334, CRC Press, 2015.

L. Ammayappan, L. K. Nayak, D. P. Ray, S. Das, and A. K. Roy, J. Nat. Fibers, 10, 390 (2013).

H. Akiyama, K. Fujii, O. Yamasaki, T. Oono, and K. Iwatsuki, J. Antimicrob. Chemother., 48, 487 (2001).

E. Cadahia, E. Conde, M. C. García-Vallejo, and B. Fernández de Simón, Phytochem. Anal, 8, 78 (1997).

Acknowledgment

The authors are very much grateful to Visva-Bharati University for allowing carrying out this research work.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Roy Maulik, S., Chakraborty, L. & Pandit, P. Evaluation of Cellulosic and Protein Fibers for Coloring and Functional Finishing Properties Using Simultaneous Method with Eucalyptus Bark Extract as a Natural Dye. Fibers Polym 22, 711–719 (2021). https://doi.org/10.1007/s12221-021-0092-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-021-0092-0