Abstract

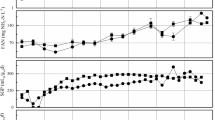

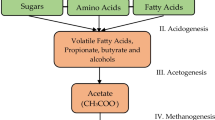

Biogas production by anaerobic digestion is an attractive approach to producing clean fuel biomethane and reducing environmental pollution. However, many fluctuations in production occur during a batch digestion period. This study investigated the dynamics of microbial communities involved in biogas production during a 20-day digestion of rice straw (RS) at 35 °C. The results demonstrated roughly consistent trends in biogas and methane production and revealed distinct stages of production. The lowest and peak methane yields were 82 ± 19.9 mL/(L•day) at day 3 and 328.5 ± 0.9 mL/(L•day) at day 8, respectively, whereas most (97.1%) of the methane was produced in the first 14 days of digestion. Ultimately, the biogas potential of RS reached 393.2 ± 13.6 mL/g added volatile solids (CH4% = 57.1%), and the logistic model best fitted actual methane production compared to the modified Gompertz, first-order kinetic, and Cone models. The microbial communities at different critical stages are a clear reflection of the biochemical dynamics in digesters. The bacterial genera Bacteroides and Clostridium_sensu_stricto_1 were the dominant microorganisms at the early stage of digestion, while the archaeal genus Methanosarcina was significantly more abundant at the peak stage of methane production than at other times during the digestion. This study demonstrates the detailed micro- and macro-conditions that exist during the fluctuating and constant digestion of RS, which will benefit industrial applications during the anaerobic digestion of RS.

Similar content being viewed by others

Data Availability

All the data and materials are available with the corresponding author and may be provided on request.

References

Chandra R, Takeuchi H, Hasegawa T (2012) Methane production from lignocellulosic agricultural crop wastes: a review in context to second generation of biofuel production. Renew Sust Energ Rev 16(3):1462–1476. https://doi.org/10.1016/j.rser.2011.11.035

Chandra R, Takeuchi H, Hasegawa T (2012) Hydrothermal pretreatment of rice straw biomass: a potential and promising method for enhanced methane production. Appl Energy 94:129–140. https://doi.org/10.1016/j.apenergy.2012.01.027

Kainthola J, Shariq M, Kalamdhad AS, Goud VV (2019) Enhanced methane potential of rice straw with microwave assisted pretreatment and its kinetic analysis. J Environ Manag 232:188–196. https://doi.org/10.1016/j.jenvman.2018.11.052

Lei Z, Chen J, Zhang Z, Sugiura N (2010) Methane production from rice straw with acclimated anaerobic sludge: effect of phosphate supplementation. Bioresour Technol 101(12):4343–4348. https://doi.org/10.1016/j.biortech.2010.01.083

Liu Q, Pan S, Long Z, Li Z, Du L, Wei Y (2020) Assessment of fresh and dry rice straw for biogas potential by anaerobic digestion. Bioenerg Res 13:845–852. https://doi.org/10.1007/s12155-020-10106-x

Wagner A, Lackner N, Mutschlechner M, Prem E, Markt R, Illmer P (2018) Biological pretreatment strategies for second-generation lignocellulosic resources to enhance biogas production. Energies 11(7):1797. https://doi.org/10.3390/en11071797

Senbayram M, Chen R, Wienforth B, Herrmann A, Kage H, Mühling KH, Dittert K (2014) Emission of N2O from biogas crop production systems in northern Germany. Bioenerg Res 7(4):1223–1236. https://doi.org/10.1007/s12155-014-9456-2

Rasapoor M, Young B, Brar R, Sarmah A, Zhuang WQ, Baroutian S (2020) Recognizing the challenges of anaerobic digestion: critical steps toward improving biogas generation. Fuel 261:114697. https://doi.org/10.1016/j.fuel.2019.116497

Menardo S, Airoldi G, Balsari P (2012) The effect of particle size and thermal pre-treatment on the methane yield of four agricultural by-products. Bioresour Technol 104:708–714. https://doi.org/10.1016/j.biortech.2011.10.061

Yu Q, Tian Z, Liu J, Zhou J, Yan Z, Yong X, Jia H, Wu X, Wei P (2018) Biogas production and microbial community dynamics during the anaerobic digestion of rice straw at 39–50 °C: a pilot study. Energ Fuel 32(4):5157–5163. https://doi.org/10.1021/acs.energyfuels.7b04042

Sabeeh M, Zeshan LR, Maryam A (2020) Effect of alkaline and alkaline-photocatalytic pretreatment on characteristics and biogas production of rice straw. Bioresour Technol 309:123449. https://doi.org/10.1016/j.biortech.2020.123449

Awe OW, Zhao Y, Nzihou A, Minh DP, Lyczko N (2017) A review of biogas utilisation, purification and upgrading technologies. Waste Biomass Valori 8(2):267–283. https://doi.org/10.1007/s12649-016-9826-4

Kainthola J, Kalamdhad AS, Goud VV (2019) Enhanced methane production from anaerobic co-digestion of rice straw and Hydrilla verticillata and its kinetic analysis. Biomass Bioenergy 125:8–16. https://doi.org/10.1016/j.biombioe.2019.04.011

Syaichurrozi I (2018) Biogas production from co-digestion Salvinia molesta and rice straw and kinetics. Renew Energ 115:76–86. https://doi.org/10.1016/j.renene.2017.08.023

Tsapekos P, Kougias PG, Treu L, Campanaro S, Angelidaki I (2017) Process performance and comparative metagenomic analysis during co-digestion of manure and lignocellulosic biomass for biogas production. Appl Energy 185:126–135. https://doi.org/10.1016/j.apenergy.2016.10.081

Li L, He Q, Ma Y, Wang X, Peng X (2015) Dynamics of microbial community in a mesophilic anaerobic digester treating food waste: relationship between community structure and process stability. Bioresour Technol 189:113–120. https://doi.org/10.1016/j.biortech.2015.04.015

Pan S, Chi Y, Zhou L, Li Z, Du L, Wei Y (2020) Evaluation of squeezing pretreatment for improving methane production from fresh banana pseudo-stems. Waste Manag 102:900–908. https://doi.org/10.1016/j.wasman.2019.12.011

Federation WE (2005) Standard methods for the examination of water and wastewater. American Public Health Association (APHA), Washington, DC

Hansen KH, Angelidaki I, Ahring BK (1998) Anaerobic digestion of swine manure: inhibition by ammonia. Water Res 32(1):5–12. https://doi.org/10.1016/S0043-1354(97)00201-7

Kim J, Kim H, Baek G, Lee C (2017) Anaerobic co-digestion of spent coffee grounds with different waste feedstocks for biogas production. Waste Manag 60:322–328. https://doi.org/10.1016/j.wasman.2016.10.015

Van Soest PJ, Robertson JB, Lewis BA (1991) Methods for dietary fiber, neutral detergent fiber, and nonstarch polysaccharides in relation to animal nutrition. J Dairy Sci 74(10):3583–3597. https://doi.org/10.3168/jds.S0022-0302(91)78551-2

Pan S, Wen C, Liu Q, Chi Y, Mi H, Li Z, Du L, Huang R, Wei Y (2019) A novel hydraulic biogas digester controlling the scum formation in batch and semi-continuous tests using banana stems. Bioresour Technol 286:121372. https://doi.org/10.1016/j.biortech.2019.121372

El-Mashad HM (2013) Kinetics of methane production from the codigestion of switchgrass and Spirulina platensis algae. Bioresour Technol 132:305–312. https://doi.org/10.1016/j.biortech.2012.12.183

Wachemo AC, Tong H, Yuan H, Zuo X, Korai RM, Li X (2019) Continuous dynamics in anaerobic reactor during bioconversion of rice straw: rate of substance utilization, biomethane production and changes in microbial community structure. Sci Total Environ 687:1274–1284. https://doi.org/10.1016/j.scitotenv.2019.05.411

Buswell AM, Mueller HF (1952) Mechanism of methane fermentation. Ind Eng Chem 44(3):550–552. https://doi.org/10.1021/ie50507a033

Chen Y, Cheng JJ, Creamer KS (2008) Inhibition of anaerobic digestion process: a review. Bioresour Technol 99(10):4044–4064. https://doi.org/10.1016/j.biortech.2007.01.057

Sun C, Cao W, Banks CJ, Heaven S, Liu R (2016) Biogas production from undiluted chicken manure and maize silage: a study of ammonia inhibition in high solids anaerobic digestion. Bioresour Technol 218:1215–1223. https://doi.org/10.1016/j.biortech.2016.07.082

Hagos K, Zong J, Li D, Liu C, Lu X (2017) Anaerobic co-digestion process for biogas production: progress, challenges and perspectives. Renew Sust Energ Rev 76:1485–1496. https://doi.org/10.1016/j.rser.2016.11.184

Steinhaus B, Garcia ML, Shen AQ, Angenent LT (2007) A portable anaerobic microbioreactor reveals optimum growth conditions for the methanogen Methanosaeta concilii. Appl Environ Microbiol 73(5):1653–1658. https://doi.org/10.1128/AEM.01827-06

Xu R, Zhang K, Liu P, Khan A, Xiong J, Tian F, Li X (2018) A critical review on the interaction of substrate nutrient balance and microbial community structure and function in anaerobic co-digestion. Bioresour Technol 247:1119–1127. https://doi.org/10.1016/j.biortech.2017.09.095

Ariunbaatar J, Panico A, Esposito G, Pirozzi F, Lens PNL (2014) Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl Energy 123:143–156. https://doi.org/10.1016/j.apenergy.2014.02.035

Weiss S, Tauber M, Somitsch W, Meincke R, Muller H, Berg G et al (2010) Enhancement of biogas production by addition of hemicellulolytic bacteria immobilised on activated zeolite. Water Res 44(6):1970–1980. https://doi.org/10.1016/j.watres.2009.11.048

Rojas-Sossa JP, Murillo-Roos M, Uribe L, Uribe-Lorio L, Marsh T, Larsen N, Chen R, Miranda A, Solís K, Rodriguez W, Kirk D, Liao W (2017) Effects of coffee processing residues on anaerobic microorganisms and corresponding digestion performance. Bioresour Technol 245:714–723. https://doi.org/10.1016/j.biortech.2017.08.098

Chen H, Chang S (2017) Impact of temperatures on microbial community structures of sewage sludge biological hydrolysis. Bioresour Technol 245:502–510. https://doi.org/10.1016/j.biortech.2017.08.143

Jabari L, Gannoun H, Cayol JL, Hedi A, Sakamoto M, Falsen E, Ohkuma M, Hamdi M, Fauque G, Ollivier B, Fardeau ML (2012) Macellibacteroides fermentans gen. nov., sp. nov., a member of the family Porphyromonadaceae isolated from an upflow anaerobic filter treating abattoir wastewaters. Int J Syst Evol Microbiol 62:2522–2527. https://doi.org/10.1099/ijs.0.032508-0

Zhou J, Yang J, Yu Q, Yong X, Xie X, Zhang L, Wei P, Jia H (2017) Different organic loading rates on the biogas production during the anaerobic digestion of rice straw: a pilot study. Bioresour Technol 244:865–871. https://doi.org/10.1016/j.biortech.2017.07.146

Liu C, Li H, Zhang Y, Si D, Chen Q (2016) Evolution of microbial community along with increasing solid concentration during high-solids anaerobic digestion of sewage sludge. Bioresour Technol 216:87–94. https://doi.org/10.1016/j.biortech.2016.05.048

Pelletier E, Kreimeyer A, Bocs S, Rouy Z, Gyapay G, Chouari R et al (2008) Candidatus Cloacamonas acidaminovorans: genome sequence reconstruction provides a first glimpse of a new bacterial division. J Bacteriol 190(7):2572–2579. https://doi.org/10.1128/JB.01248-07

Gao S, Zhao M, Chen Y, Yu M, Ruan W (2015) Tolerance response to in situ ammonia stress in a pilot-scale anaerobic digestion reactor for alleviating ammonia inhibition. Bioresour Technol 198:372–379. https://doi.org/10.1016/j.biortech.2015.09.044

Belostotskiy DE, Ziganshina EE, Siniagina M, Boulygina EA, Miluykov VA, Ziganshin AM (2015) Impact of the substrate loading regime and phosphoric acid supplementation on performance of biogas reactors and microbial community dynamics during anaerobic digestion of chicken wastes. Bioresour Technol 193:42–52. https://doi.org/10.1016/j.biortech.2015.06.066

Acknowledgments

The authors thank the Jushang Testing & Analysis Center for providing elemental measurements. The authors also thank the International Science Editing for providing language assistance.

Funding

This research was financially supported by the Central Government Directs Special Funds for Local Science and Technology Development Projects (Grant No. ZY1949015) and the Scientific Research and Technology Development Program of Guangxi (Grant No. 1644901).

Author information

Authors and Affiliations

Contributions

YTW and ZCL conceived and designed this research. SYP, QQL, and CW performed the experiments. SYP, QQL, CW, and LQD analyzed and interpreted the data. SYP and QQL composed the manuscript. ZCL and YTW improved the manuscript. All authors reviewed and revised the manuscript prior to publication.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Ethical Approval

This article does not contain any studies with animals performed by any of the authors.

Consent to Participate

All the authors consent to participate.

Consent for Publication

All the authors consent to publication.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pan, S., Liu, Q., Wen, C. et al. Producing Biogas from Rice Straw: Kinetic Analysis and Microbial Community Dynamics. Bioenerg. Res. 14, 1338–1348 (2021). https://doi.org/10.1007/s12155-020-10226-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-020-10226-4