Abstract

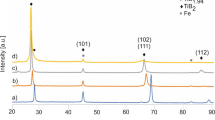

Composites reinforced with 8 vol% TiB2 were subjected to the consolidation process by spark plasma sintering (SPS). The results show that the addition of boron (1 vol%) introduced to the steel matrix has a significant effect on the composite microstructure, as well as physical, mechanical and tribological properties. The full density of 97–99% was obtained in the composites sintered at a temperature of 1100∘C. The steel–8% TiB2–1% B composite sintered at 1100∘C for 30 min was characterized by the highest microhardness (465 HV0.3) and Young’s modulus (229 GPa), combined with the best compressive strength (1150 MPa) and abrasive wear resistance (μ = 0.25 and W V(disc) = 207.78 × 10−6 mm3 N−1m−1). The microstructure and chemical composition were examined by scanning electron microscopy and transmission electron microscopy. The examinations have revealed the presence of numerous fine complex borides in the microstructure of the steel–8% TiB2 and steel–8% TiB2–1% B composites.

Similar content being viewed by others

References

Novak C J, Peckner D and Bernstein I M editors 1977 Handbook of stainless steels (New York: McGraw-Hill)

Clyne T W and Withers P J editors 1993 An introduction to metal matrix composites (Cambridge: Cambridge University Press)

Sulima I, Klimczyk P and Malczewski P 2014 Acta Metall. Sin. (Engl. Lett.) 27 112

Srivastava A K and Das K 2008 Mater. Lett. 62 3947

Patankar S N and Tan M J 2000 Powder Metall. 43 350

Velasco F, Anton N, Torralba J M and Ruiz-Prieto J M 1997 Mater. Sci. Technol. 13 847

Vardavoullus M, Jeandin M, Velasco F and Torralba J M 1996 Tribol. Int. 29 499

Farid A, Guo S, Cui F, Feng P and Lin T 2007 Mater. Lett. 61 189

Sulima I, Jaworska L and Figiel P 2014 Arch. Metall. Mater. 59 205

Pandya S, Ramakrishna K S, Annamalai A R and Upadhyaya A 2012 Mater. Sci. Eng. A556 271

German R M 1994 Powder metallurgy science (Princeton, NJ, USA: Metal Powder Industries Federation) 2nd edn, p 21

Zhaohui Z, Fuch W, Lin W, Shukui L and Osamu S 2008 Mater. Lett. 62 3987

Tokita M 2000 Sci. Technol. 3 251

Kurgan N 2014 Mater. Des. 55 235

Kazior J, Molinari A, Pieczonka T and Straffelini G 1998 Mater. Eng. 3 335

Panda S S, Singh V, Upadhyaya A and Agrawal D 2006 Scr. Mater. 54 2179

Molinari A, Kazior J, Marchetti F, Cantieri R, Cristofolini A and Tiziani A 1994 Powder Metall. 37 115

Molinari A, Straffelini G, Pieczonka T and Kazior J 1998 Int. J. Powder Metall. 34 21

Almathami A and Brochu M 2010 J. Mater. Proc. Technol. 210 2119

Madan D S and German R M 1986 Mod. Dev. Powder Metall. 15 441

Skałon M and Kazior J 2012 Arch. Metall. Mater. 57 789

Molinari A, Menapace C, Kazior J and Pieczonka T 2007 Mater. Sci. 534–536 553

Madan D S and German R M 1989 Adv. Powder Metall. 1 147

Molinari A, Kazior J and Straffelini G 1995 Mater. Charact. 34 271

Karwan-Baczewska J 2011 Arch. Metall. Mater. 56 789

Tojal C, Gómez-Acebo T and Castro F 2007 Mater. Sci. Forum 534–536 661

Bakan H I, Heaney D and German R M 2001 Powder Metall. 44 235

Pellizzari M, Fedrizzi A and Zadra M 2011 Mater. Des. 32 1796

Dybkov V, Lengauer W and Barmak K J 2005 J. Alloys Compd. 398 113

Molinari A Straffelini G, Kazior J and Pieczonka T 1996 Adv. Powder Metall. Part Mater. 5 12

Gierl Ch, Mohsin I U and Danninger H 2008 Powder Metall. Prog. 8 135

Cabral-Miramontes J A, Barceinas-Sánchez J D O, Almeraya-Calderón F, Martinez-Villafaňe A and Chacón-Nava J G 2010 J. Mater. Eng. Perform. 19 880

Yilmaz R and Ekici M R 2008 J. Achieve. Mater. Manuf. Eng. 31 23

Karwan-Baczewska J 2015 Arch. Metall. Mater. 60 41

Abenojar J, Esteban D, Martinez M A and Velasco F 2007 Mater. Sci. Forum 534–536 733

Karwan-Baczewska J and Rosso M 2001 Powder Metall. 44 221

Tanaka K and Saito T 1999 J. Phase Equilibria 20 207

Bacon D H and Edwards L 2012 Int. J. Fatigue 48 39

Nahme H, Lach E and Tarrant A 2008 J. Mater. Sci. 44 463

Zheng R, Hao X, Yuan Y, Wang Z, Ameyama K and Ma Ch 2013, J. Alloys Compd. 576 291

Zhang Z H, Shen X B, Wang F C., Lee S K, Fan Q B and Cao M S 2012 Scr. Mater. 66 167

Saheb N, Iqbal Z, Khalil A, Hakeem A S, Aqeeli N A, Laoui T, Al-Qutub A and Kirchner R 2012 J. Nanomater. Article ID 983470 doi:10.1155/2012/983470

Tjong S C and Lau K C 1999 Mater. Lett. 4 153

Tjong S C and Lau K C 2000 Compos. Sci. Technol. 60 1141

Mousavi Abarghouie S M R and Seyed Reihani S M 2010 J. Alloys Compd. 501 326

Degnan C C, Shipway P H and Wood J V 2001 Wear 251 1444

Sullivan J L and Athwal S S 1983 Tribol. Int. 16 123

Wang C J and Li C C 2004 Oxid. Met. 61 485

Shariff N A, Jalar A, Sahri M I and Othman N K 2014 Sains Malays. 43 1069

Acknowledgement

This study was performed under statutory funds of Faculty of Mathematics, Physics and Technical Science, Pedagogical University in Krakow. We thank Professor Lucyna Jaworska (Institute of Advanced Manufacturing Technology in Krakow) for help in SPS process, Tomasz Tokarski, Ph.D. (AGH University of Science and Technology, Krakow), and Sonia Boczkal, Ph.D. (Institute of Non-Ferrous Metals in Gliwice, Light Metals Division Skawina), for help with the SEM and TEM investigations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

SULIMA, I. Role of boron addition on the consolidation and properties of steel composites prepared by SPS. Bull Mater Sci 38, 1831–1841 (2015). https://doi.org/10.1007/s12034-015-0984-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-0984-y