Abstract

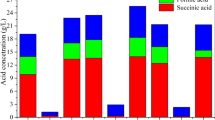

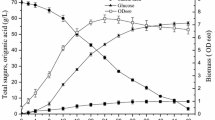

To develop a cost-effective fermentation medium, spent brewer's yeast hydrolysate was evaluated as a nitrogen source for succinic acid production by Actinobacillus succinogenes NJ113 in glucose-containing media. Autolysis and enzymatic hydrolysis were used to hydrolyze the spent brewer's yeast cells to release the nutrients. The results showed that enzymatic hydrolysis was a more effective method due to the higher succinic acid yield and cell growth. However, the incomplete glucose consumption indicated existence of nutrient limitation. Vitamins were subsequently identified as the main limiting factors for succinic acid production using enzymatically hydrolyzed spent brewer's yeast as a nitrogen source. After the addition of vitamins, cell growth and succinic acid concentration both improved. As a result, 15 g/L yeast extract could be successfully replaced with the enzymatic hydrolysate of spent brewer's yeast with vitamins supplementation, resulting in a production of 46.8 g/L succinic acid from 68 g/L glucose.

Similar content being viewed by others

References

Bechthold, I., Bretz, K., Kabasci, S., Kopitzky, R., & Springer, A. (2008). Succinic acid: a new platform chemical for biobased polymers from renewable resources. Chemical Engineering & Technology, 31, 647–654. doi:10.1002/ceat.200800063.

McKinlay, J., Vieille, C., & Zeikus, J. G. (2007). Prospects for a bio-based succinate industry. Applied Microbiology and Biotechnology, 76, 727–740. doi:10.1007/s00253-007-1057-y.

Song, H., & Lee, S. Y. (2006). Production of succinic acid by bacterial fermentation. Enzyme and Microbial Technology, 39, 352–361. doi:10.1016/j.enzmictec.2005.11.043.

Willke, T., & Vorlop, K.-D. (2004). Industrial bioconversion of renewable resources as an alternative to conventional chemistry. Applied Microbiology and Biotechnology, 66, 131–142. doi:10.1007/s00253-004-1733-0.

Lee, P. C., Lee, S. Y., Hong, S. H., & Chang, H. N. (2002). Isolation and characterization of a new succinic acid-producing bacterium, Mannheimia succiniciproducens MBEL55E from bovine rumen. Applied Microbiology and Biotechnology, 58, 663–668. doi:10.1007/s00253-002-0935-6.

Kim, D. Y., Yim, S. C., Lee, P. C., & Lee, W. G. (2004). Batch and continuous fermentation of succinic acid from wood hydrolysate by Mannheimia succiniciproducens MBEL55E. Enzyme and Microbial Technology, 35, 648–653. doi:10.1016/j.enzmictec.2004.08.018.

Guettler, M. V., Rumler, D., & Jain, M. K. (1999). Actinobacillus succinogenes sp. nov., a novel succinic-acid-producing strain from the bovine rumen. International Journal of Systematic Bacteriology, 49, 207–216.

Guettler, M.V., Jain, M.K., & Rumler, D. (1996). Method for making succinic acid, bacterial variants for use in the process, and methods for obtaining variants. US patent 5,504,004.

Van der Werf, M. J., Guettler, M. V., Jain, M. K., & Zeikus, J. G. (1997). Environmental and physiological factors affecting the succinate product ratio during carbohydrate fermentation by Actinobacillus sp. 130Z. Archives of Microbiology, 167, 332–342. doi:10.1007/s002030050452.

Urbance, S. E., Pometto, A. L., III, Dispirito, A. A., & Denli, Y. (2004). Evaluation of succinic acid continuous and repeat-batch biofilm fermentation by Actinobacillus succinogenes using plastic composite support bioreactors. Applied Microbiology and Biotechnology, 65, 664–670. doi:10.1007/s00253-004-1634-2.

Datta, R. (1992). Process for the production of succinic acid by anaerobic fermentation. US patent 5,143,833.

Lee, P. C., Lee, W. G., Lee, S. Y., & Chang, H. N. (1999). Effects of medium components on the growth of Anaerobiospirillum succiniciproducens and succinic acid production. Process Biochemistry, 35, 49–55. doi:10.1016/S0032-9592(99)00031-X.

Lee, P. C., Lee, W. G., Kwon, S., Lee, S. Y., & Chang, H. N. (1999). Succinic acid production by Anaerobiospirillum succiniciproducens: effects of the H2/CO2 supply and glucose concentration. Enzyme and Microbial Technology, 24, 549–554. doi:10.1016/S0141-0229(98)00156-2.

Vemuri, G. N., Eiteman, M. A., & Altman, E. (2002). Succinate production in dual-phase Escherichia coli fermentations depends on the time of transition from aerobic to anaerobic conditions. Journal of Industrial Microbiology & Biotechnology, 28, 325–332. doi:10.1038/sj.jim.7000250.

Lin, H., Bennett, G. N., & San, K. Y. (2005). Metabolic engineering of aerobic succinate production systems in Escherichia coli to improve process productivity and achieve the maximum theoretical succinate yield. Metabolic Engineering, 7, 116–127. doi:10.1016/j.ymben.2004.10.003.

Lee, P. C., Lee, S. Y., Hong, S. H., Chang, H. N., & Park, S. C. (2003). Biological conversion of wood hydrolysate to succinic acid by Anaerobiospirillum succiniciproducens. Biotechnology Letters, 25, 111–114. doi:10.1023/A:1021907116361.

Urbance, S. E., Pometto, A. L., III, DiSpirito, A. A., & Demirci, A. (2003). Medium evaluation and plastic composite support ingredient selection for biofilm formation and succinic acid production by Actinobacillus succinogenes. Food Biotechnology, 17, 53–65. doi:10.1081/FBT-120019984.

Xu, H., Liu, J. J., & Zhao, X. Y. (2008). Comprehensive utilization of brewer's yeast. Liquor Making, 35, 47–49. in Chinese.

York, S. W., & Ingram, L. O. (1996). Ethanol production by recombinant Escherichia coli KO11 using crude yeast autolysate as a nutrient supplement. Biotechnology Letters, 18, 683–688. doi:10.1007/BF00130766.

Rivas, B., Moldes, A. B., Dominguez, J. M., & Parajo, J. C. (2004). Development of culture media containing spent yeast cells of Debaryomyces hansenii and corn steep liquor for lactic acid production with Lactobacillus rhamnosus. International Journal of Food Microbiology, 97, 93–98. doi:10.1016/j.ijfoodmicro.2004.05.006.

Marica, R., Maja, V., Slavica, S. M., & Milan, M. (2007). Contribution of lactic acid fermentation to improved nutritive quality vegetable juiced enriched with brewer's yeast autolysate. Food Chemistry, 100, 599–602. doi:10.1016/j.foodchem.2005.09.077.

McKinlay, J. B., Zeikus, J. G., & Vieille, C. (2005). Insights into Actinobacillus succinogenes fermentative metabolism in a chemically defined growth medium. Applied and Environmental Microbiology, 71, 6651–6656. doi:10.1128/AEM.71.11.6651-6656.2005.

Press editors. (2003). National standard assembly of China. Beijing: Standard Press of China.

Lee, P. C., Lee, S. Y., Hong, S. H., & Chang, H. N. (2003). Batch and continuous cultures of Mannheimia succiniciproducens MBEL55E for the production of succinic acid from whey and corn steep liquor. Bioprocess and Biosystems Engineering, 26, 63–67. doi:10.1007/s00449-003-0341-1.

Liu, Y. P., Zheng, P., Sun, Z. H., Ni, Y., Dong, J. J., & Zhu, L. L. (2007). Economical succinic acid production from cane molasses by Actinobacillus succinogenes. Bioresource Technology, 99, 1736–1742. doi:10.1016/j.biortech.2007.03.044.

Agarwal, L., Isar, J., Meghwanshi, G. K., & Saxena, R. K. (2006). A cost effective fermentative production of succinic acid from cane molasses and corn steep liquor by Escherichia coli. Journal of Applied Microbiology, 100, 1348–1354. doi:10.1111/j.1365-2672.2006.02894.x.

Champagne, C. P., Barrette, J., & Goulet, J. (1999). Interaction between pH, autolysis promoters and bacterial contamination on the production of yeast extracts. Food Research International, 32, 575–583. doi:10.1016/S0963-9969(99)00133-7.

Tatjana, V. M., Marica, R., & Slavica, I. M. (2007). Utilization of baker's yeast (Saccharomyces cerevisiae) for the production of yeast extract: effects of different enzymatic treatments on solid, protein and carbohydrate recovery. Journal of the Serbian Chemical Society, 72, 451–457. doi:10.2298/JSC0705451V.

John, R. P., Nampoothiri, K. M., & Pandey, A. (2007). Fermentative production of lactic acid from biomass: an overview on process developments and future perspectives. Applied Microbiology and Biotechnology, 74, 524–534. doi:10.1007/s00253-006-0779-6.

Kwon, S., Lee, P. C., Lee, E. G., Chang, Y. K., & Chang, N. (2000). Production of lactic acid by Lactobacillus rhamnosus with vitamin-supplemented soybean hydrolysate. Enzyme and Microbial Technology, 26, 209–215. doi:10.1016/S0141-0229(99)00134-9.

Li, Z., Ding, S. F., Li, Z. P., & Tan, T. W. (2006). l-Lactic acid production by lactobacillus casei fermentation with corn steep liquor-supplemented acid-hydrolysate of soybean meal. Biotechnology Journal, 1, 1453–1458. doi:10.1002/biot.200600099.

Gao, M. T., Hirata, M., Toorisaka, E., & Hano, T. (2007). Lactic acid production with the supplementation of spent cells and fish wastes for the purpose of reducing impurities in fermentation broth. Biochemical Engineering Journal, 36, 276–280. doi:10.1016/j.bej.2007.02.030.

Gao, M. T., Hirata, M., Toorisaka, E., & Hano, T. (2006). Study on acid-hydrolysis of spent cells for lactic acid fermentation. Biochemical Engineering Journal, 28, 87–91. doi:10.1016/j.bej.2005.09.006.

Du, C., Carol Lin, K. C., Koutinas, A., Wang, R., & Webb, C. (2007). Succinic acid production from wheat using a biorefining strategy. Applied Microbiology and Biotechnology, 76, 1263–1270. doi:10.1007/s00253-007-1113-7.

Acknowledgements

This work was supported by grant no. 2006AA02Z235 from “863” Program of China, grant no. 20606017 from National Natural Science Foundation of China, grant no. 2009CB724701 from “973” Program of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, M., Chen, K., Liu, Z. et al. Succinic Acid Production by Actinobacillus succinogenes Using Spent Brewer's Yeast Hydrolysate as a Nitrogen Source. Appl Biochem Biotechnol 160, 244–254 (2010). https://doi.org/10.1007/s12010-009-8649-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-009-8649-1