Abstract

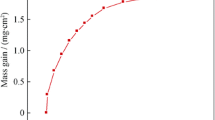

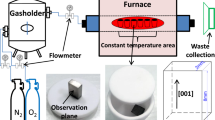

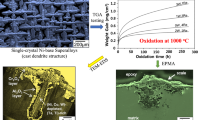

The fourth-generation nickel-based single-crystal superalloys, which contain large amounts of refractory metals for strengthening and platinum group metals for topologically close-packed phase prevention, show excellent high-temperature strength. However, these alloying elements seem to decrease high-temperature oxidation resistance. In this study, nickel-based superalloys with various amounts of tantalum, rhenium, and ruthenium were examined in isothermal and cyclic exposures at 1,100°C to investigate the effect on the oxide growth rate and resistance to scale spallation. Ruthenium and rhenium were found to degrade the oxidation resistance by the vaporization of their oxide. Tantalum-rich oxide in the spinel layer acts to stabilize ruthenium and rhenium oxide in the scale. The addition of hafnium and yttrium is effective in improving the oxidation resistance of ruthenium-containing nickel-based superalloys.

Similar content being viewed by others

References

R. Darolia et al., “Formation of Topologically Closed Packed Phases in Nickel Base Single Crystal Superalloys,” Superalloys 1988 ed. S. Reichman et al. (Warrendale, PA: TMS, 1988), pp. 255–264.

T. Hino et al., “Development of a New Single Crystal Superalloy for Industrial Gas Turbines,” Superalloys 2000, ed. T.M. Pollock et al., (Warrendale, PA: TMS, 2000), pp. 729–736.

A. Sato et al., “TTT Diagram for TCP Phases Precipitations of 4th Generation Ni-Base Superalloys”, J. Japan Inst. Metals, 68 (2004), pp. 507–510.

Y. Koizumi et al., “Development of 4th Generation Single Crystal Superalloys,” Proceedings of 2nd International Symposium on High-Temperature Materials, (Tsukuba, Japan, 31 May–2 June, 2001), pp. 30–31.

J.X. Zhang et al., “Interfacial Dislocation Networks Strengthening a Fourth-Generation Single-Crystal TMS-138 Superalloy”, Metall. Mater. Trans. A, 33A (2002), pp. 3741–3746.

S. Seal et al., “Studies on the Surface Chemistry of Oxide Films Formed on IN-738LC Superalloy at Elevated Temperatures in Dry Air”, Oxid. Met., 56 (2001), pp. 581–603.

S. Seal et al., “Surface Chemistry of Oxide Scale on IN-738LC Superalloy: Effect of Long-Term Exposure in Air at 1173 K”, Oxid. Met., 57 (2002), pp. 297–322.

S. Shinharoy and L. Narasimhan, “Oxidation Behavior of Two Nickel-Base Superalloys Used as Elevated Temperature Valves in Spark Ignited Engines and Diesel Exhaust Recirculation (EGR) Applications”, Superalloys 2004, ed. K.A. Green et al., (Warrendale, PA: TMS, 2004), pp. 623–626.

B. Wang et al., “Oxidation Behaviour of the Alloy IC-6 and Protective Coatings”, Corros. Sci., 46 (2004), pp. 519–528.

M.H. Li et al., “Oxidation Behavior of a Single-Crystal Ni-Base Superalloy in Air—I: At 800 and 900°C”, Oxid. Met., 59 (2003), pp. 591–605.

M.H. Li et al., “Oxidation Behavior of a Single-Crystal Ni-Base Superalloy in Air—II: At 1000, 1100, and 1150°C”, Oxid. Met., 60 (2003), pp. 195–210.

K. Onal et al., “The Effect of Water Vapor on the Oxidation of Nickel-Base Superalloys and Coatings at Temperatures from 700°C to 1100°C”, Superalloys 2004, ed. K.A. Green et al., (Warrendale, PA: TMS, 2004), pp. 607–615.

K. Kawagishi et al., “Effect of Alloying Elements on the Oxidation Behavior of 4th Generation Ni-base Single-crystal Superalloys”, TMS Lett., 2 (2005), pp. 23–24.

K. Kawagishi et al., “Oxidation Behavior of Rucontaining Ni-base Single-crystal Superalloys”, submitted to Mater. Sci. Forum.

A. Sato et al., “Yttrium Doping for Oxidation Resistance of a 4th Generation Ni-Base Superalloy TMS-138”, TMS Lett., 2 (2005), pp. 19–20.

B.A. Pint et al., “Substrate and Bond Coat Compositions: Factors Affecting Alumina Scale Adhesion”, Mater. Sci. Eng. A, 245 (1998), pp. 201–211.

D.A. Ford et al., “Improved Performance CMSX-4 Alloy Turbine Blades Utilising PPM Levels of Lanthanum and Yttrium” (Paper presented at the 6th Liège Conference, Materials for Advanced Power Engineering, Liège, Belgium, 5–7 October 1998).

Y. Koizumi et al., “Development of Next Generation Nickel-Base Single Crystal Superalloys”, Superalloys 2004, ed. K.A. Green et al., (Warrendale, PA: TMS, 2004), pp. 35–43.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Kawagishi, K., Harada, H., Sato, A. et al. The oxidation properties of fourth generation single-crystal nickel-based superalloys. JOM 58, 43–46 (2006). https://doi.org/10.1007/s11837-006-0067-z

Issue Date:

DOI: https://doi.org/10.1007/s11837-006-0067-z