Abstract

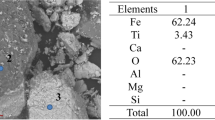

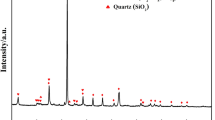

Magnetite is a kind of iron ore that is difficult to carburize. In order to improve the carburizing performance of magnetite pellet, pre-oxidation treatment was carried out, and the oxidation, reduction and carburization behaviors of magnetite pellet were investigated in this study. The magnetite pellet was oxidized in the air and carburized in CO-CO2-H2 gas mixtures, the oxidation, reduction and carburization behaviors were demonstrated by detecting phase change, microstructure, carburizing index via thermogravimetry, X-ray diffraction (XRD), infrared carbon-sulfur analyzer, and scanning electron microscope (SEM). The results show that the dense magnetite particles inside pellet are oxidized to porous hematite particles, and the Fe3O4 transforms to Fe2O3 with high lattice defect concentration during the pre-oxidation process. Then the porous hematite particles and newly formed Fe2O3 significantly promote the reduction efficiency. Porous metallic iron particles are produced in the reduction process. Finally, both high reduction efficiency and the porous structure of metallic iron particles dramatically enhance the carburization efficiency of pellet. High pre-oxidation temperature favors to the carburization of magnetite pellet. However, the carburized index decreases due to the recrystallization of iron oxide when the temperature extends to 1000 ° C. The optimum pre-oxidation temperature for magnetite pellet carburization is 900 °C.

摘要

磁铁矿是一种难渗碳的铁矿石。为了提高磁铁矿球团的渗碳性能,本文对磁铁矿球团进行了预 氧化处理,并进一步研究了磁铁矿球团的氧化、还原和渗碳行为。磁铁矿球团在空气中进行氧化并在 CO-CO2-H2气氛中进行渗碳,利用热重分析仪、X射线衍射仪(XRD)、红外碳硫分析仪和扫描电子显微 镜(SEM)研究产物的渗碳指数、微观结构和物相变化,以揭示磁铁矿的氧化、还原和渗碳行为。结果 表明:在预氧化过程中,球团中致密的磁铁矿颗粒被氧化为多孔的赤铁矿颗粒,Fe3O4转化为晶格缺陷 较高的Fe2O3,多孔的赤铁矿颗粒和新生的Fe2O3显著提高了球团的还原速率;在还原过程中,多孔的 赤铁矿颗粒被还原为多孔的金属铁颗粒,球团的高还原速率和金属铁颗粒的多孔结构显著提高了球团 的渗碳效率;较高的预氧化温度有利于磁铁矿球团的渗碳,但当氧化温度增加到1000 °C时,由于氧 化铁的再结晶,其预氧化球团的渗碳指数反而有所降低;磁铁矿球团渗碳的最佳预氧化温度为900 °C。

Similar content being viewed by others

References

EDSTRÖM J O, von SCHEELE J. Sponge iron and iron carbide: Competitive raw materials for high-quality steelmaking [J]. Scandinavian Journal of Metallurgy, 1997, 26(5): 196–205.

SMITHYMAN C M. Alternate iron sources for the EAF [J]. Iron and Steelmaker (I and SM), 1996, 23(8): 47–50.

BAHGAT M. Technology of iron carbide synthesis [J]. Journal of Materials Science & Technology, 2006, 22(3): 423–432.

HWANG H S, CHUNG U C, CHUNG W S, et al. Carburization of iron using CO — H2 gas mixture [J]. Metals and Materials International, 2004, 10(1): 77–82. DOI: https://doi.org/10.1007/BF03027366.

PARK E, OSTROVSKI O, ZHANG Jian-qiang, et al. Characterization of phases formed in the iron carbide process by X-ray diffraction, Mossbauer, X-ray photoelectron spectroscopy, and Raman spectroscopy analyses [J]. Metallurgical and Materials Transactions B, 2001, 32(5): 839–845. DOI: https://doi.org/10.1007/s11663-001-0071-1.

HAYASHI S, IGUCHI Y. Synthesis of iron carbide by reaction of iron ores with H2-CO gas mixtures bearing traces of sulfur [J]. ISIJ International, 1997, 37(1): 16–20. DOI: https://doi.org/10.2355/isijinternational.37.16.

HAYASHI S, IGUCHI Y. Iron carbide synthesis by reaction of iron ore with H2-CH4 gas mixtures containing traces of sulfur [J]. ISIJ International, 1997, 37(4): 345–349. DOI: https://doi.org/10.2355/isijinternational.37.345.

IGUCHI Y, SAWAI S, OHIWA K. Kinetics of carbide formation from reduced iron in CO-H2-H2S mixtures [J]. Metallurgical and Materials Transactions B, 2001, 32(6): 1161–1170. DOI: https://doi.org/10.1007/s11663-001-0103-x.

HAYASHI S, IGUCHI Y. Production of iron carbide from iron ores in a fluidized bed [J]. ISIJ International, 1998, 38(10): 1053–1061. DOI: https://doi.org/10.2355/isijinternational.38.1053.

LI Guang-qiang, MA Jiang-hua, NI Hong-wei, et al. Influences of oxide additions on formation reaction of iron carbide at 1023 K [J]. ISIJ International, 2006, 46(7): 981–986. DOI: https://doi.org/10.2355/isijinternational.46.981.

KAPELYUSHIN Y, SASAKI Y, ZHANG Jian-qiang, et al. A study of cementite formation in the reduction of hematite by CO-CO2 gas mixture using high temperature XRD [C]// Extraction 2018, The Minerals, Metals & Materials Series. Cham: Springer, 2018. DOI: https://doi.org/10.1007/978-3-319-95022-8_54.

YU Jun, GE Ying-yong, CAI Xin-wei. The desulfurization of magnetite ore by flotation with a mixture of xanthate and dixanthogen [J]. Minerals, 2016, 6(3): 70. DOI: https://doi.org/10.3390/min6030070.

AROL A I, AYDOGAN A. Recovery enhancement of magnetite fines in magnetic separation [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2004, 232(2–3): 151–154. DOI: https://doi.org/10.1016/j.colsurfa.2003.06.003.

WANG Shao-yan, GUO Ke, QI Shuo-kun, et al. Effect of frictional grinding on ore characteristics and selectivity of magnetic separation [J]. Minerals Engineering, 2018, 122: 251–257. DOI: https://doi.org/10.1016/j.mineng.2018.04.015.

ZHANG Han-quan, LU Man-man, FU Jin-tao. Oxidation and roasting characteristics of artificial magnetite pellets [J]. Journal of Central South University, 2016, 23(11): 2999–3005. DOI: https://doi.org/10.1007/s11771-016-3363-y.

CHEN Dong, GUO Hong-wei, ZHANG Shun-hu, et al. Carburization behavior of siderite pellets in CO-CO2-H2 mixtures [J]. Steel Research International, 2019, 90(3): 1800433. DOI: https://doi.org/10.1002/srin.201800433.

ZHANG Han-quan, FU Jin-tao. Oxidation behavior of artificial magnetite pellets [J]. International Journal of Minerals, Metallurgy, and Materials, 2017, 24(6): 603–610. DOI: https://doi.org/10.1007/s12613-017-1442-1.

LIANG Ru-quan, YANG Shuo, YAN Fu-sheng, et al. Kinetics of oxidation reaction for magnetite pellets [J]. Journal of Iron and Steel Research, International, 2013, 20(9): 16–20. DOI: https://doi.org/10.1016/S1006-706X(13)60150-8.

PARK E, OSTROVSKI O. Effects of preoxidation of titania-ferrous ore on the ore structure and reduction behavior [J]. ISIJ International, 2004, 44(1): 74–81. DOI: https://doi.org/10.2355/isijinternational.44.74.

WANG Zhen-yang, ZHANG Jian-liang, JIAO Ke-xin, et al. Effect of pre-oxidation on the kinetics of reduction of ironsand [J]. Journal of Alloys and Compounds, 2017, 729: 874–883. DOI: https://doi.org/10.1016/j.jallcom.2017.08.293.

JIANG T. Principle and technology of agglomeration of iron ores [M]. Changsha: Central South University Press, 2016. (in Chinese)

ZHANG Z L. Fundamental research on high alumina iron ore by gas-based direct reduction [D]. Shenyang: Northeastern University, 2014. (in Chinese)

CHEN Dong, ZHU De-qing, HONG Lan, et al. Preparation of pre-reduced pellet using pyrite cinder containing nonferrous metals with high temperature chloridizingreduction roasting technology—Effect of CaCl2 additive [J]. Journal of Central South University, 2015, 22(11): 4154–4161. DOI: https://doi.org/10.1007/s11771-015-2962-3.

WANG De-yong, MIN Yi, LIU Cheng-jun, et al. Study on iron carbide production with CO-CO2-H2 mixing gas [J]. The Chinese Journal of Process Engineering, 2007, 7(2): 332–336. (in Chinese)

SCNLRRDR E R, VNNUAAS F H S. Differential thermal analysis and cell dimensions of some natural magnetites [J]. American Mineralogist, 1955, 40(5–6): 422–431.

ZBORIL R, MASHLAN M, PETRIDIS D. Iron(III) oxides from thermal ProcessesSynthesis, structural and magnetic properties, Mössbauer spectroscopy characterization, and applications [J]. Chemistry of Materials, 2002, 14(3): 969–982. DOI: https://doi.org/10.1021/cm0111074.

ZHANG Y M. Theory and technology of pelletizing [M]. Beijing: Metallurgical Industry Press, 2008. (in Chinese)

PAN Jian, YU Hong-bin, ZHU De-qing, et al. Influence of MgO sources on behavior of preheated pellets of magnetite concentrate [J]. Journal of Central South University (Science and Technology), 2016, 47(6): 1823–1829. (in Chinese)

FU Ju-ying, LI Yun-tao, JIANG Chang-wei, et al. Oxidation kinetics of magnetite concentrate pellets [J]. Journal of Central South University of Technology (Natural Science), 2004, 35(6): 950–954. (in Chinese)

BENTELL L, MATHISSON G. Oxidation and slag-forming process in dolomite-fluxed pellets based on magnetite concentrates [J]. Scandinavian Journal of Metallurgy, 1978, 7(5): 230–236.

FORSMO S P E, FORSMO S E, SAMSKOG P O, et al. Mechanisms in oxidation and sintering of magnetite iron ore green pellets [J]. Powder Technology, 2008, 183(2): 247–259. DOI: https://doi.org/10.1016/j.powtec.2007.07.032.

PINEAU A, KANARI N, GABALLAH I. Kinetics of reduction of iron oxides by H2: Part I: Low temperature reduction of hematite [J]. Thermochimica Acta, 2006, 447(1): 89–100. DOI: https://doi.org/10.1016/j.tca.2005.10.004.

WEI Zheng, ZHANG Jing, QIN Bao-ping, et al. Reduction kinetics of hematite ore fines with H2 in a rotary drum reactor [J]. Powder Technology, 2018, 332: 18–26. DOI: https://doi.org/10.1016/j.powtec.2018.03.054.

ZHENG Heng, SPREITZER D, WOLFINGER T, et al. Effect of prior oxidation on the reduction behavior of magnetite-based iron ore during hydrogen-induced fluidized bed reduction [J]. Metallurgical and Materials Transactions B, 2021, 52(4): 1955–1971. DOI: https://doi.org/10.1007/s11663-021-02215-5.

GUPTA S K, RAJAKUMAR V, GRIEVESON P. The influence of weathering on the reduction of llmenite with carbon [J]. Metallurgical Transactions B, 1989, 20(5): 735–745. DOI: https://doi.org/10.1007/BF02655932.

MERK R, PICKLES C A. Reduction of ilmenite by carbon monoxide [J]. Canadian Metallurgical Quarterly, 1988, 27(3): 179–185. DOI: https://doi.org/10.1179/cmq.1988.27.3.179.

SUN Hao-yan, ADETORO A A, PAN Feng, et al. Effects of high-temperature preoxidation on the titanomagnetite ore structure and reduction behaviors in fluidized bed [J]. Metallurgical and Materials Transactions B, 2017, 48(3): 1898–1907. DOI: https://doi.org/10.1007/s11663-017-0925-9.

MA Jiang-hua, LI Guang-qiang. Effects of iron ore porosity on its reduction and iron carbide formation [J]. The Chinese Journal of Process Engineering, 2007, 7(6): 1132–1137. (in Chinese)

AMAYA-RONCANCIO S, ARROYO-GÓMEZ J J, LINARES D H, et al. Direct versus hydrogen-assisted dissociation of CO on iron surfaces: Kinetic Monte Carlo and microkinetic modeling [J]. Journal of Molecular Structure, 2020, 1201: 127188. DOI: https://doi.org/10.1016/j.molstruc.2019.127188.

GENG S, DING W, GUO S, et al. Carbon deposition on iron surfaces in CO-CO2 atmosphere [J]. Ironmaking & Steelmaking, 2015, 42(9): 714–720. DOI: https://doi.org/10.1179/1743281215y.0000000049.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item

Project(U1960104) supported by the National Natural Science Foundation of China; Project(LYU Ya-nan) supported by the Jiangsu Colleges and Universities Qing Lan Project, China

Contributors

CHEN Dong provided the concept and edited the draft of manuscript. CHEN Suo conducted the literature review and wrote the first draft of the manuscript. LYU Ya-nan and WU Fei-bao analyzed the measured data. LYU Ya-nan, WU Fei-bao, and YIN Wei-ang edited the draft of manuscript. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

CHEN Suo, CHEN Dong, LYU Ya-nan, WU Fei-bao, and YIN Wei-ang declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chen, S., Chen, D., Lyu, Yn. et al. Reduction and subsequent carburization of pre-oxidation magnetite pellets. J. Cent. South Univ. 29, 1856–1868 (2022). https://doi.org/10.1007/s11771-022-5066-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-5066-x