Abstract

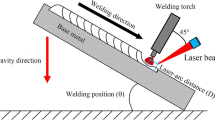

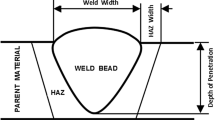

This paper presents the results obtained by the optimization of laser bead on plate welding parameters for 3.5 kW cooled slab laser using Taguchi technique. The trials were conducted on two different shielding gases 100% Nitrogen and 50% Nitrogen + 50% Argon. The input process parameters such as beam power, travel speed and focal position are selected suitably in order to obtain the desired output i.e., bead width and depth of penetration. The quality of the weld is evaluated by studying the features of weld bead geometry. Grey relational analysis is applied to optimize the input parameters simultaneously considering multiple output variables. In this investigation the nearest optimal solution which would improve the weld quality was found out. Experimental trial on super austenitic stainless steel has been conducted to validate the optimized parameters. Further, the optimized parameters were evaluated through the microstructural characterization and hardness measurements across the weld zone.

Similar content being viewed by others

References

Steen WM (1991) J Laser Appl 11(5): 216, Springer, London

Anawa EM, Olabi AG, Hashmi MSJ (2006) Optimization of ferritic/austenitic laser welded components. Paper 04, AMPT 2006 international conference, Las Vegas, Nevada, USA

Benjounis KY, Olabi AG, Hasmi MSJ (2005) Effect of laser welding parameters on the heat input and weld-bead profile. J Mater Process Technol 164–165:978–985

Olabi AG, Benyounis KY, Hashmi MSJ (2007) Application of response surface methodology in describing the residual stress distribution in CO2 laser welding of AISI 304. Strain 43(1):37–46

Benjounis KY, Olabi AG, Hasmi MSJ (2005) Estimation of mechanical properties of laser welded joints using RSM. International Proceedings of IMC22 Institute of Technology Tallaght, Dublin, Ireland, pp 565–571

Benjounis KY, Olabi AG, Hasmi MSJ (2005) Residual stress prediction for CO2 laser butt–welding of 304-stainless steel. Appl Mech Mater 3–4:125–130

Benyounis KY, Olabi AG, Hashmi MSJ (2008) Multi-response optimization of CO2 laser-welding process of austenitic stainless steel. Opt Laser Technol 40:76–87

Benyounis KY, Olabi AG, Hashmi MSJ (2008) Optimization the laser-welded butt joints of medium carbon steel using RSM. J Mater Process Technol 164–165:986–989

Tarng YS, Yang WH (1998) Optimisation of the weld bead geometry in gas Tungsten Arc welding by the Taguchi Method. J Adv Manuf Technol 14:549–554

Chou DS, Pan LK, Chang BD (2001) Optimization for solidification of low-level-radioactive resin using Taguchi analysis. Waste Manag 21:762–772

Tong LI, Su CT, Wang CH (1997) The optimization of multi response problems in the Taguchi method. Int J Qual Reliab Manag 14(4):367–380

Tosun N (2006) Determination of optimum parameters for multi performance characteristics in drilling by using grey relational analysis. Int J Adv Manuf Technol 28:450–455

Molian PA (1985) Solidification behavior of laser welded stainless steel. J Mater Sci Lett 4:281–283

Heino S, Knutson-wedel EM, Karlsson B (1995) Precipitation behavior in heat affected zone of welded super austenitic stainless steel. J Mater Sci Technol 15(1):101–108

Suutala N (1983) Effect of solidification conditions on the solidification mode in austenitic stainless steels. Metall Mater Trans A 14:191–197

Acknowledgments

We would like to express our deepest appreciation to the Department of Science & Technology (DST), New Delhi, India for their guidance and financial assistance to this research under Fast Track Proposal SR/FTP/ETA-11/2007. We further wish to convey our gratitude to Mr. B. Shanmugarajan and Dr. G. Padmanabham for offering us the distinguished opportunity to use the laser welding trials at the International Advanced Research Centre for powder metallurgy & New materials, Hyderabad 500 005, Andhra Pradesh, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sathiya, P., Abdul Jaleel, M.Y. & Katherasan, D. Optimization of welding parameters for laser bead-on-plate welding using Taguchi method. Prod. Eng. Res. Devel. 4, 465–476 (2010). https://doi.org/10.1007/s11740-010-0234-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-010-0234-5