Abstract

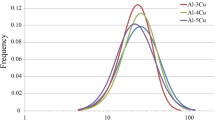

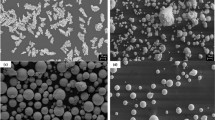

Pure Al coatings were fabricated on Cu substrates via kinetic spraying to produce a thermally activated reactive Cu liner. The coatings need to endure high-strain rate severe plastic deformation and react with oxygen during penetration or after penetration of the liner. In this study, the Al powder underwent large exothermic reactions with a small particle size and fast heating rate, as determined from the differential scanning calorimetric analysis. Process optimization of the Al deposition was facilitated by defining the “critical velocity” of an Al particle in the kinetic spraying process based on numerical modeling and computations using ABAQUS finite element codes. The simulation results revealed that the critical velocity of an Al particle at room temperature (RT) is 780 m/s and it decreases as the particle temperature increases. Certain process conditions resulted in improved coating properties as the temperature of the particles was affected by the process gas temperature and pressure. The mechanical properties such as the bond strength of the coatings formed under various process conditions were evaluated and compared. The relationships between the resulting properties, processing conditions, and the structures of the coatings are discussed.

Similar content being viewed by others

References

J.F. Molinari, Finite Element Simulation of Shaped Charges, Finite Elem. Anal. Des., 2002, 38, p 921-936

C. Feng, L.E. Murr, and C.-S. Niou, Aspects of Dynamic Recrystallization in Shaped Charge and Explosively Formed Projectile Devices, Metall. Mater. Trans. A, 1996, 27, p 1773-1778

M. Held, Liners for Shaped Charges, J. Battlefield Technol., 2001, 4(3), p 1-7

A. Doig, Some Metallurgical Aspects of Shaped Charge Liners, J. Battlefield Technol., 1998, 1(1), p 1-3

T.J. Schilling, Reactive-Injecting Follow-Through Shaped Charges from Sequent-Material Conical Liners, Propellants Explos. Pyrotech., 2007, 32, p 307-313

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56, p 4858-4868

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51, p 4379-4394

K. Kang, S. Yoon, Y. Ji, and C. Lee, Oxidation Dependency of Critical Velocity for Aluminum Feedstock Deposition in Kinetic Spraying Process, Mater. Sci. Eng. A, 2008, 486, p 300-307

Y. Ji, G. Bae, K. Kang, and C. Lee, Influence of the Interface Temperature and Strain Gradients on the Impact Energy Model of a Soft Particle on a Hard Substrate during Kinetic Spraying, Met. Mater. Int., 2011, 17(2), p 335-340

ABAQUS, ABAQUSTM. 6.7-2 User Manual. Hibbit Karlsson and Soerensen, Pawtucket, RI, 2007

G. Bae, S. Kumar, S. Yoon, K. Kang, H. Na, H.-J. Kim, and C. Lee, Bonding Features and Associated Mechanisms in Kinetic Sprayed Titanium Coatings, Acta Mater., 2009, 57, p 5654-5666

J. Wu, H. Fang, S. Yoon, H.-J. Kim, and C. Lee, Measurement of Particle Velocity and Characterization of Deposition in Aluminum Alloy Kinetic Spraying Process, Appl. Surf. Sci., 2005, 252, p 1368-1377

A.P. Alkhimow, V.F. Kosarey, and S.V. Klinkow, The Features of Cold Spray Nozzle Design, J. Therm. Spray Technol., 2001, 10, p 375-381

J. Wu, J. Yang, H. Fang, S. Yoon, and C. Lee, The Bond Strength of Al-Si Coating on Mild Steel by Kinetic Spraying Deposition, Appl. Surf. Sci., 2006, 252, p 7809-7814

M.A. Trunov, M. Schoenitz, and E.L. Dreizin, Ignition of Aluminum Powders Under Different Experimental Conditions, Propellants Explos. Pyrotech., 2005, 30, p 36-43

M.A. Trunov, M. Schoenitz, X. Zhu, and E.L. Dreizin, Effect of Polymorphic Phase Transformations in Al2O3 Film on Oxidation Kinetics of Aluminum Powders, Combust. Flame, 2005, 140, p 310-318

V. Rosenband, Thermo-Mechanical Aspects of the Heterogeneous Ignition of Metal, Combust. Flame, 2004, 137, p 366-375

J. Wu, H. Fang, S. Yoon, H.-J. Kim, and C. Lee, The Rebound Phenomenon in Kinetic Spraying Deposition, Scripta Mater., 2006, 54, p 665-669

G. Bae, K. Kang, H. Na, J.-J. Kim, and C. Lee, Effect of Particle Size on the Microstructure and Properties of Kinetic Sprayed Nickel Coatings, Surf. Coat. Technol., 2010, 204, p 3326-3335

G. Bae, J.-I. Jang, and C. Lee, Correlation of Particle Impact Conditions with Bonding Nanocrystal Formation and Mechanical Properties in Kinetic Sprayed Nickel, Acta Mater., 2012, 60, p 3524-3535

H. Assadi, T. Schmidt, H. Richter, J.-O. Kliemann, K. Binder, F. Gärtner, T. Klassen, and H. Kreye, On Parameter Selection in Cold Spraying, J. Therm. Spray Technol., 2011, 20(6), p 1161-1176

C.-J. Li and W.-Y. Li, Microstructure Evolution of Cold-Sprayed Coating During Deposition and Through Post-spraying heat Treatment, Trans. Nonferrous Met. Soc. China, 2004, 14, p 49-54

W. Wong, E. Irissou, A.N. Ryabinin, J. Legoux, and S. Yue, Influence of Helium and Nitrogen Gases on the Properties of Cold Gas Dynamic Sprayed Pure Titanium Coatings, J. Therm. Spray Technol., 2010, 20(1-2), p 213-226

P.C. King, S. Zahiri, M. Jahedi, and J. Friend, Aluminium Coating of Lead Zirconate Titanate: A Study of Cold Spray Variables, Surf. Coat. Technol., 2010, 205, p 2016-2022

J. Pattison, S. Celotto, A. Khan, and W. O’Neill, Standoff Distance and Bow Shock Phenomena in the Cold Spray Process, Surf. Coat. Technol., 2008, 202, p 1443-1454

T. Schmidt, H. Assadi, F. Gärtner, H. Richer, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5-6), p 794-808

Acknowledgments

This work was supported by an Agency for Defense Development (ADD) grant funded by the Korean government (MOST) (No. 111115-911004001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Won, J., Bae, G., Kang, K. et al. Bonding, Reactivity, and Mechanical Properties of the Kinetic-Sprayed Deposition of Al for a Thermally Activated Reactive Cu Liner. J Therm Spray Tech 23, 818–826 (2014). https://doi.org/10.1007/s11666-014-0088-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0088-z