Abstract

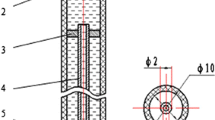

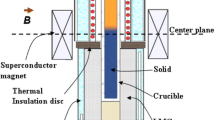

Hypoeutectic Al-19 wt.% Cu alloys were directionally solidified at two different growth speeds in cylindrical molds that featured an abrupt increase in cross-section, from 3.2 to 9.5 mm in diameter. The effects of thermosolutal convection and shrinkage flow induced by the cross-section change on macrosegregation were investigated. Dendrite clustering and extensive radial macrosegregation were seen, particularly in the larger cross-section after expansion. Negative longitudinal macrosegregation right after the cross-section increase was observed; the extent of macrosegregation, however, decreases with increasing growth speed. Both thermal and flow effects due to cross-section change were seen to influence the radial macrosegregation immediately before, and after the expansion. Radial macrosegregation pattern was found to be changing as the mushy zone enters the larger cross-section region above the cross-section change where the solidification is in its unsteady state. The effect of the solutal expansion coefficient on macrosegregation was studied by comparing the degree of thermosolutal convection in Al-19 wt.% Cu with a previous study in which we investigated Al-7 wt.% Si. A two-dimensional model accounting for both shrinkage and thermosolutal convection was used to simulate the resulting steepling, as well as the axial and radial macrosegregation. The experimentally observed macrosegregation associated with the expansion during directional solidification is well predicted by the numerical simulations.

Similar content being viewed by others

Notes

In this article, “wt.%” is dropped, so Al-4.5 wt.% Cu is simply designated as Al-4.5Cu and so on.

References

G. Reinhart, C.A. Gandin, N. Mangelinck-Noël, H. Nguyen-Thi, J.E. Spinelli, J. Baruchel, and B. Billia, Influence of Natural Convection During Upward Directional Solidification: A Comparison Between in Situ X-ray Radiography and Direct Simulation of the Grain Structure, Acta Mater., 2013, 61(13), p 4765–4777

C.H. Desch, Some Common Defects Occurring in Alloys, J. Inst. Metals, 1910, 4, p 235–246

M.H. Burden, D.J. Hebditch, and J.D. Hunt, Macroscopic Stability of a Planar, Cellular or Dendritic Interface During Directional Freezing, J. Cryst. Growth, 1973, 20(2), p 121–124

D.G. McCartney and J.D. Hunt, Measurements of Cell and Primary Dendrite Arm Spacings in Directionally Solidified Aluminium Alloys, Acta Metall., 1981, 29(11), p 1851–1863

J.T. Mason, J.D. Verhoeven, and R. Trivedi, Primary Dendrite Spacing: Part II. Experimental Studies of Pb-Pd and Pb-Au Alloys, Metall. Mater. Trans. A, 1984, 15(9), p 1665–1676

J.D. Verhoeven, J.T. Mason, and R. Trivedi, The Effect of Convection on the Dendrite to Eutectic Transition, Metall. Trans. A, 1986, 17(6), p 991–1000

M.D. Dupouy, D. Camel, and J.J. Favier, Natural Convection in Directional Dendritic Solidification of Metallic Alloys—I. Macroscopic Effects, Acta Metall., 1989, 37(4), p 1143–1157

M.D. Dupouy, D. Camel, and J.J. Favier, Natural Convective Effects in Directional Dendritic Solidification of Binary Metallic Alloys: Dendritic Array Primary Spacing, Acta Metall. Mater., 1992, 40(7), p 1791–1801

M.D. Dupouy and D. Camel, Effects of Gravity on Columnar Dendritic Growth of Metallic Alloys: Flow Pattern and Mass Transfer, J. Cryst. Growth, 1989, 183(3), p 469–489

H.N. Thi, Y. Dabo, B. Drevet, M.D. Dupouy, D. Camel, B. Billia, J.D. Hunt, and A. Chilton, Directional Solidification of Al-1.5 wt% Ni Alloys Under Diffusion Transport in Space and Fluid-Flow Localisation on Earth, J. Cryst. Growth, 2005, 281(2), p 654–668

B. Billia, H.N. Thi, G. Reinhart, Y. Dabo, B.H. Zhou, Q.S. Liu, T. Lyubimova, B. Roux, and C.W. Lan, Tailoring of Dendritic Microstructure in Solidification Processing by Crucible Vibration/Rotation, Microgravity Sci. Technol., 2005, 16(1-4), p 15–19

C. Weiss, N. Bergeon, N. Mangelinck-Noël, and B. Billia, Effects of the Interface Curvature on Cellular and Dendritic Microstructures, J. Mater. Sci. Eng. A, 2005, 413, p 296–301

B.H. Zhou, H. Jung, N. Mangelinck-Noël, H. Nguyen-Thi, B. Billia, Q.S. Liu, and C.W. Lan, Comparative Study of the Influence of Natural Convection on Directional Solidification of Al-3.5 wt% Ni and Al-7 wt% Si Alloys, Adv. Space Res., 2008, 41(12), p 2112–2117

G. Reinhart, C.A. Gandin, N. Mangelinck-Noël, H. Nguyen-Thi, B. Billia, J. Baruchel, Direct simulation of a directional solidification experiment observed in situ and real-time using x-ray imaging, in IOP Conference Series: Materials Science and Engineering, vol. 33(1), (2012), p. 012077 (in English)

M. Ghods, L. Johnson, M. Lauer, R.N. Grugel, S.N. Tewari, and D.R. Poirier, Radial Macrosegregation and Dendrite Clustering in Directionally Solidified Al-7Si and Al-19Cu Alloys, J. Cryst. Growth, 2016, 441, p 107–116

M.C. Flemings and G.E. Nereo, Macrosegregation: Part I, Trans. TMS-AIME, 1967, 239, p 1449–1461

M.C. Flemings, R. Mehrabian, and G.E. Nereo, Macrosegregation: Part II, Trans. TMS-AIME, 1968, 242, p 41–49

M.C. Flemings and G.E. Nereo, Macrosegregation: Part III, Trans. TMS-AIME, 1968, 242, p 50–55

R. Sellamuthu, H.D. Brody, and A.F. Giamei, Effect of Fluid Flow and Hafnium Content on Macrosegregation in the Directional Solidification of Nickel Base Super Alloys, Metall. Trans. B, 1986, 17(2), p 347–356

S.D. Felicelli, D.R. Poirier, and J.C. Heinrich, Macrosegregation Patterns in Multicomponent Ni-Base Alloys, J. Cryst. Growth, 1997, 177(1–2), p 145–161

S. Felicelli, D.R. Poirier, A.F. Giamei, and J.C. Heinrich, Simulating Convection and Macrosegregation in Superalloys, JOM, 1997, 49(3), p 21–25

S.D. Felicelli, J.C. Heinrich, and D.R. Poirier, Finite Element Analysis of Directional Solidification of Multicomponent Alloys, Int. J. Numer. Methods Fluids, 1998, 27(1–4), p 207–227

S.D. Felicelli, D.R. Poirier, and P.K. Sung, A Model for Prediction of Pressure and Redistribution of Gas-Forming Elements in Multicomponent Casting Alloys, Metall. Mater. Trans. B, 2000, 31(6), p 1283–1292

C.A. Gandin and M. Rappaz, A Coupled Finite Element-Cellular Automaton Model for the Prediction of Dendritic Grain Structures in Solidification Processes, Acta Metall. Mater., 1994, 42(7), p 2233–2246

C.A. Gandin, R.J. Schaefer, and M. Rappaz, Analytical and Numerical Predictions of Dendritic Grain Envelopes, Acta Mater., 1996, 44(8), p 3339–3347

M. Rappaz, C.A. Gandin, J.L. Desbiolles, and P. Thevoz, Prediction of Grain Structures in Various Solidification Processes, Metall. Mater. Trans. A, 1996, 27(3), p 695–705

M. Ghods, M. Lauer, R.N. Grugel, S.N. Tewari, and D.R. Poirier, Convection and Macrosegregation in Al-19Cu Alloy Directionally Solidified Through an Abrupt Contraction in Cross-Section: A Comparison with Al-7Si, J. Cryst. Growth, 2017, 459, p 135–145

M. Ghods, L. Johnson, M. Lauer, R.N. Grugel, S.N. Tewari, and D.R. Poirier, Macrosegregation in Al-7Si Alloy Caused by Abrupt Cross-Section Change During Directional Solidification, J. Cryst. Growth, 2016, 449, p 134–147

D.R. Poirier, P.J. Nandapurkar, and S. Ganesan, The Energy and Solute Conservation Equations for Dendritic Solidification, Metall. Trans. B, 1991, 22(6), p 889–900

S. Ganesan and D.R. Poirier, Conservation of Mass and Momentum for the Flow of Interdendritic Liquid During Solidification, Metall. Mater. Trans. B, 1990, 21(1), p 173–181

S.D. Felicelli, J.C. Heinrich, and D.R. Poirier, Simulation of Freckles During Vertical Solidification of Binary Alloys, Metall. Mater. Trans. B, 1991, 22(6), p 847–859

S.D. Felicelli, J.C. Heinrich, and D.R. Poirier, Numerical Model for Dendritic Solidification of Binary Alloys, Numer. Heat Transf. B, 1993, 23(4), p 461–481

M.A. Lauer, D.R. Poirier, R.G. Erdmann, L. Johnson, S.N. Tewari, Simulations of the effects of mold properties on directional solidification, in ASME 2013 International Mechanical Engineering Congress and Exposition (2013), p. V02BT02A002 (in English)

M.A. Lauer, Modeling Macrosegregation in Directionally Solidified Aluminum Alloys, Ph.D. dissertation (The University of Arizona, Tucson, 2015)

C.B. Meher-Homji, G. Gabriles, Gas turbine blade failures—causes, avoidance, and troubleshooting, in Proceedings of the 27th Turbomachinery Symposium, Houston, TX (1998), pp. 129–179

R. Kurz, C.B. Meher-Homji, K. Brun, Gas turbine degradation, in Proceedings of the 43rd Turbomachinery Symposium, Houston, TX (2014), pp. 1–36

A.M. Kolagar, N. Tabriz, M. Cheraghzadeh, and M.S. Shahriari, Failure Analysis of Gas Turbine First Stage Blade Made of Nickel-Based Superalloy, Case Stud. Eng. Fail. Anal., 2017, 8, p 61–68

M. McLean, Directionally Solidified Materials for High Temperature Service, The Metals Society, J.W. Arrowsmith Ltd, Bristol, 1983, p 8

Acknowledgments

This work was supported by NASA Grants NX10AV40G and NNX14AM18G. The Al-19% Cu and Al-7% Si alloys for this research were kindly provided by Dr. Men G. Chu at ALCOA Technical Center. M. Lauer would like to acknowledge support from the Sandia National Laboratories Campus Executive Fellowship program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghods, M., Lauer, M., Grugel, R.N. et al. Macrosegregation Due to Convection in Al-19Cu Alloy Directionally Solidified Through an Abrupt Expansion in Cross-Section: A Comparison with Al-7Si. J. of Materi Eng and Perform 26, 4876–4889 (2017). https://doi.org/10.1007/s11665-017-2925-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2925-y