Abstract

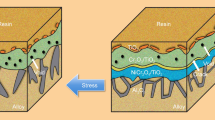

To improve the high-temperature reliability of sintered Ag joints, three types of silicon carbide particle (SiCp) of different size and morphology were added to Ag micron-flake paste. Quality sintered joints between Cu dummy chips and Cu substrate were obtained at a relatively low temperature (250°C), in air, under low load (0.4 MPa), and 35 MPa die-shear strength was achieved. High-temperature stability was investigated by means of aging tests at 150, 200, and 250°C for 500 h, and by thermal cycling between −50°C and 250°C for up to 170 cycles. The best distribution and compatibility with porous sintered Ag structures was observed for sub-micron SiC particles with an average diameter of 600 nm. After high-temperature storage for 500 h at 250°C, mean Ag grain size of the SiC-containing joints was unchanged whereas that for pure sintered Ag increased from 1.1 to 2.5 μm. Ag joints containing the optimum amount (2 wt.%) of SiCp retained their original strength (20 MPa) after storage at 250°C for 500 h. The shear strength of Ag joints without added SiCp decreased from 27 to 7 MPa after 500 h because of grain growth, which obeyed the classical parabolic law. Grain growth in pure Ag joints is discussed in terms of a temperature-dependent exponent n and activation energy Q. Our SiCp-containing joints resisted the grain growth that induces interfacial cracks during thermal cycling.

Similar content being viewed by others

References

Y.S. Park, SiC Materials and Devices (San Diego: Academic Press, 1998).

J. Biela, M. Schweizer, S. Waffler, and J.W. Kolar, IEEE Trans. Ind. Electron. 58, 2872 (2011).

S. Ogata, D. Takayama, K. Asano, and Y. Sugawara, Electr. Eng. Jpn. 171, 1 (2010).

R.W. Johnson, J.L. Evans, P. Jacobsen, J.R.R. Thompson, and M. Christopher, IEEE Trans. Electron. Packag. Manufact 27, 164 (2004).

P. Godignon, X. Jorda, M. Vellvehi, X. Perpina, V. Banu, D. Lopez, J. Barbero, P. Brosselard, and S. Massetti, IEEE Trans. Ind. Electron 58, 2582 (2011).

K. Park, D. Seo, and J. Lee, Colloid Surf. A 313–314, 351 (2008).

M. Wu, B. Lin, Y. Cao, J. Song, Y. Sun, H. Yang, and X. Zhang, J. Mater. Sci.: Mater. Electron. 24, 4913 (2013).

F. Le Henaff, S. Azzopardi, J.Y. Deletage, E. Woirgard, S. Bontemps, and J. Joguet, Microelectron. Reliab. 52, 2321 (2012).

V.R. Manikam and K.Y. Cheong, IEEE Trans. Compon. Packag. Manufact. Technol. 1, 457 (2011).

K. Suganuma, S. Sakamoto, N. Kagami, D. Wakuda, K.S. Kim, and M. Nogi, Microelectron. Reliab. 52, 375 (2012).

S. Sakamoto, T. Sugahara, and K. Suganuma, J. Mater. Sci.: Mater. Electron. 24, 1332 (2012).

S. Sakamoto, S. Nagao, and K. Suganuma, J. Mater. Sci.: Mater. Electron. 24, 2593 (2013).

J. Lu, Y. Mu, X. Luo, and J. Niu, Mat. Sci. Eng. B-Solid. 177, 1759 (2012).

T. Ozben, E. Kilickap, and O. Çakır, J. Mater. Process. Technol. 198, 220 (2008).

C. Zweben, JOM-US. 50, 47-51 (1998).

C.H. Zweben, Adv. Microelectron. 37, 14 (2010).

N. Heuck, A. Langer, A. Stranz, G. Palm, R. Sittig, A. Bakin, and A. Waag, IEEE Trans. Compon. Packag. Manufact. Technol. 1, 1846 (2011).

N.E. Davis, J. Newman, P.B. Wheelock, and A.K. Kronenberg, Phys. Chem. Miner. 38, 123 (2011).

K. Michibayashi and H. Imoto, Phys. Chem. Miner. 39, 213 (2012).

Y.F. Xu, D.Q. Yi, H.Q. Liu, B. Wang, and F.L. Yang, Mater. Sci. Eng. A. 529, 326 (2011).

R. Ren, Y.C. Wu, W.M. Tang, F.T. Wang, T.G. Wang, and Z.X. Zheng, Trans. Nonferrous Metal. Soc. China 18, 66 (2008).

X.L. Liu, J.P. He, Q.F. Dong, and S.Z. Zhou, J. Rare Earths 19, 209 (2001).

M. Kambara, K. Uenishi, and K.F. Kobayashi, J. Mater. Sci. 35, 2897 (2000).

D.V. Quach, H. Avila-Paredes, S. Kim, M. Martin, and Z.A. Munir, Acta Mater. 58, 5022 (2010).

N. Bouhssira, M.S. Aida, A. Mosbah, and J. Cellier, J. Cryst. Growth 312, 3282 (2010).

G.C. Zhang, S.W. Feng, Z. Zhou, J. Liu, J.W. Li, and H.␣Zhou, IEEE Trans. Compon. Packag. Manufact. Technol. 2, 1346 (2012).

L.A. Navarro, X. Perpina, M. Vellvehi, V. Banu, and X. Jorda, Microelectron. Reliab. 52, 2314 (2012).

F. Dugal and M. Ciappa, Microelectron. Reliab. 54, 1856 (2014).

Acknowledgements

This study was partially supported by the Japan Society for the Promotion of Science (Grant-in-Aid for Scientific Research No. 24226017).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Nagao, S. & Suganuma, K. Addition of SiC Particles to Ag Die-Attach Paste to Improve High-Temperature Stability; Grain Growth Kinetics of Sintered Porous Ag. J. Electron. Mater. 44, 3896–3903 (2015). https://doi.org/10.1007/s11664-015-3919-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-015-3919-x