Abstract

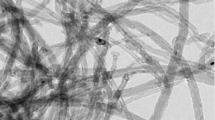

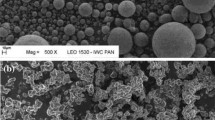

Al-SiC nanocomposites were prepared by high energy ball milling of mixtures of pure Al and 50-nm-diameter SiC nanoparticles, followed by spark plasma sintering. The final composites had grains of approximately 100 nm dimensions, with SiC particles located mostly at grain boundaries. The samples were tested in uniaxial compression by nano- and microindentation in order to establish the effect of the SiC volume fraction, stearic acid addition to the powder, and the milling time on the mechanical properties. The results are compared with those obtained for pure Al processed under similar conditions and for AA1050 aluminum. The yield stress of the nanocomposite with 1 vol pct SiC is more than ten times larger than that of AA1050. The largest increase is due to grain size reduction; nanocrystalline Al without SiC and processed by the same method has a yield stress seven times larger than AA1050. Adding 0.5 vol pct SiC increases the yield stress by an additional 47 pct, while the addition of 1 vol pct SiC leads to 50 pct increase relative to the nanocrystalline Al without SiC. Increasing the milling time and adding stearic acid to the powder during milling lead to relatively small increases of the flow stress. The hardness measured in nano- and microindentation experiments confirms these trends, although the numerical values of the gains are different. The stability of the microstructure was tested by annealing samples to 423 K and 523 K (150 °C and 250 °C) for 2 hours, in separate experiments. The heat treatment had no effect on the mechanical properties, except when treating the material with 1 vol pct SiC at 523 K (250 °C), which led to a reduction of the yield stress by 13 pct. The data suggest that the main strengthening mechanism is associated with grain size reduction, while the role of the SiC particles is mostly that of stabilizing the nanograins.

Similar content being viewed by others

References

J. Lan, Y. Yang, X. Li, Mat. Sci. Eng. A, 2004, vol. 386, pp. 284-90.

Y. Yang, J. Lan, X. Li, Mater. Sci. Eng. A, 2004, vol. 380, pp. 378-83.

S.C. Tjong, Adv. Eng. Mater., 2007, vol. 9, pp. 639-52.

D.C. Jia, Mat. Sci. Eng. A, 2000, vol. 289, pp. 83-90.

F. Tang, M. Hagiwara, J.M. Schoenung, Scripta Mater., 2005, vol. 53, pp. 619-24.

F.Y. Boey, Z. Yuan, K.A. Khor, Mater. Sci. Eng. A, 1998, vol. 252, pp. 276-87.

B.Q. Han, Z. Lee, S.R. Nutt, E.J. Lavernia, F.A. Mohamed, Metall. Mater. Trans A, 2003, vol. 34A, pp. 603-13.

G.M. Candido, V. Guido, G. Silva, K.R. Cardoso, Mater. Sci. Forum., 2012, vol. 660-661, pp. 317-24.

S. Kamrani, Z.R. Hesabi, R. Riedel, S.M.S. Reihani, Adv. Comput. Mater., 2011, vol. 20, pp. 13-27.

N.P. Cheng, S.M. Zeng, Z.Y. Liu, J. Mater. Proc. Technol., 2008, vol. 202, pp. 27-40.

Y. Saberi, S.M. Zebarjad, G.H. Akbari, J. Alloys Compd., 2009, vol. 484, pp. 637-40.

R. Narayanasamy, T. Ramesh, M. Prabhakar, Mater. Sci. Eng. A, 2009, vol. 504, pp. 13-23.

N. Parvin, R. Assadifard, P. Safarzadeh, S. Sheibani, P. Marashi, Mater. Sci. Eng. A 2008, vol. 492, pp. 134-40.

W. Gu, M. Sun, X. Wang, W. Sheng, G. Zhu, Mater. Sci. Forum, 2011, vol. 688, pp. 158-61.

S.A. Khadem, S. Nategh, H. Yoozbashizadeh, J. Alloys Compd., 2011, vol. 509, pp. 2221-26.

D. Poirier, R.A.L. Drew, M.L. Trudeau, R. Gauvin, Mater. Sci. Eng. A, 2010, vol. 527, pp. 7605-14.

J.R. Ryu, K.I. Moon, K.S. Lee, J. Alloys Compd., 2000, vol. 296, pp. 157-65.

T. Nagae, M. Yokota, M. Nose, S. Tomida, K. Otera, T. Kamiya, S. Saji, Mat. Trans., 2002, vol. 43, pp. 537-43.

G. Xie, O. Ohashi, N. Yamaguchi, Trans. Mater. Res. Soc. Jpn., 2002, vol. 27, pp. 743-46.

C. Y. Xü, S.S. Jia, Z.Y. Cao, Mater. Charct., 2005, vol. 54, pp. 394-98.

M. Zadra, F. Casari, L. Girardini, A. Molinari, Powder Metall., 2007, vol. 50, pp. 40-45.

O. Ohashi, G. Xie, Weld. Int., 2008, vol. 22, pp. 680-85.

J. Ye, B.Q. Han, Z. Lee, B. Ahn, S.R. Nutt, J.M. Schoenung, Scripta Mater., 2005, vol. 53, pp. 481-86.

M. El-Eskandarany, J. Alloys Compd., 1998, vol. 279, pp. 263-71.

C. Suryanarayana, Prog. Mater. Sci., 2001, vol. 46, pp. 1-184.

D. Poirier, J.G. Legoux, R.A.L. Drew, R. Gauvin, J. Therm. Spray, 2011, vol. 20, pp. 275-84.

J. Scharnweber, W. Skrotzki, C.G. Oertel, H.G. Brokmeier, H.W. Hoppel, I. Topic, J. Jaschinski, Adv. Eng. Mater., 2010, vol. 12, pp. 989-94.

L. Zhou and Y. Yao: Mater. Sci. Eng. A, 2007, vols. 460–461, pp. 95–100.

J.B. Fogagnolo, F. Velasco, M.H. Robert, J.M. Torralba, Mater. Sci. Eng. A, 2003, vol. 342, pp. 131-43.

Y.C. Kang, S.L.I. Chan, Mater. Chem. Phys., 2004, vol. 85, pp. 438-43.

K.R. van Horn, ed.: Aluminum, Vol. 1: Properties, Physical Metallurgy and Phase Diagrams, American Society of Metals, Ohio, 1967, p. 94.

F. Zhou, J. Lee, E.J. Lavernia, Scripta Mater., 2001, vol. 44, pp. 2013-17.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted December 29, 2012.

Rights and permissions

About this article

Cite this article

Grácio, J.J., Picu, C.R., Vincze, G. et al. Mechanical Behavior of Al-SiC Nanocomposites Produced by Ball Milling and Spark Plasma Sintering. Metall Mater Trans A 44, 5259–5269 (2013). https://doi.org/10.1007/s11661-013-1874-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1874-9