Abstract

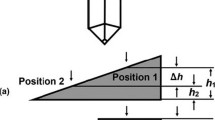

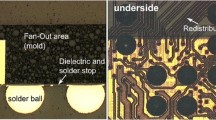

The mechanical properties of a molding compound on a packaged integrated circuit (IC) were measured by spherical nanoindentation using a 50 μm radius diamond tip. The molding compound is a heterogeneous material, consisting of assorted diameters of glass beads embedded in an epoxy. Statistical analysis was conducted to determine the representative volume element (RVE) size for a nanoindentation grid. Nanoindentation was made on the RVE to determine the effective viscoelastic properties. The relaxation functions were converted to temperature-dependent Young’s modulus at a given strain rate at several elevated temperatures. The Young’s modulus values at a given strain rate from nanoindentation were found to be in a good agreement with the corresponding data obtained from tensile samples at or below 90 °C. However, the values from nanoindentation were significantly lower than the data obtained from tensile samples when the temperature was near or higher than 110 °C, which is near the glass transition. The spatial distribution of the Young’s modulus at a given strain rate was determined using nanoindentation with a Berkovich tip. The spatial variation of the Young’s modulus at a given strain rate is due to the difference in nanoindentation sites (glass beads, epoxy or the interphase region). A graphical map made from an optical micrograph agrees reasonably well with the nanoindentation results.

Similar content being viewed by others

References

Ivankovic A, Vanstreels K, Vanderstraeten D, Brizar G, Gillon R, Blansaer E, Vandevelde B (2012) Comparison of experimental methods for the extraction of the elastic modulus of molding compounds used in IC packaging. Microelectron Reliab 52(11):2677–2684. doi:10.1016/j.microrel.2012.06.024

Zou Y, Suhling JC, Jaeger RC, Lin ST, Benoit JT, Grzybowski RR (1999) Die surface stress variation during thermal cycling and thermal aging reliability tests. Elect Compon Technol Conf IEEE. doi:10.1109/ECTC.1999.776400

Schindler-Saefkow F, Rost F, Otto A, Faust W, Wunderle B, Michel B, Rzepka S (2012) Stress chip measurements of the internal package stress for process characterization and health monitoring. 13th Int Conf on Therm Mech Multi-Phys Simul Experiments Microelectron Microsyst IEEE. doi:10.1109/ESimE.2012.6191746

Hong BZ, Su L (1998) On thermal stresses and reliability of a PBGA chip scale package. 48th IEEE Electron Compon Technol Conf. doi:10.1109/ECTC.1998.678740

Clement A, Saint-Paul M (2002) Ultrasonic measurements of microelectronic molding compounds. J Mater Sci Mater Electron 13(1):21–25. doi:10.1023/A:1013190812644

Canumalla S, Oravecz MG (1997) Non-destructive elastic property characterization of IC encapsulates. ASME Appiled Mech Divison - Pub – AMD 222:25–32

Kim YK, Park IS, Choi J (2012) Warpage mechanism analyses of strip panel type PBGA chip packaging. Microelectron Reliab 50(3):398–406. doi:10.1016/j.microrel.2009.12.010

Miyake K, Yoshida T, Baik HG, Park SW (2001) Viscoelastic warpage analysis of surface mount package. J Electron Packag 123(2):101–104

Ferry JD (1980) Viscoelastic Properties of Polymers. John Wiley & Sons, Hobooken. ISBN 0-471-04894-1

Lu H, Knauss WG (1998) The role of dilation in the nonlinear viscoelastic behavior of PMMA under multiaxial stress and in moderate deformation states. Mech Time-Depend Mater 2(4):307–334. doi:10.1023/A:1009865009935

Knauss WG, Emri I, Lu H (2008) Mechanics of Polymers: viscoelasticity. In: Sharpe WN (ed) Handbook of Experimental Solid Mechanics. Springer, New York, pp 49–95

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mater Res 7(06):1564–1583. doi:10.1557/JMR.1992.1564

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J Mater Res 19(01):3–20. doi:10.1557/jmr.2004.19.1.3

Daphalapurkar NP, Wang F, Fu B, Lu H, Komanduri R (2010) Determination of mechanical properties of sand grains by nanoindentation. Exp Mech 51:719–728. doi:10.1007/s11340-010-9373-z

Wang F, Fu B, Luo H, Staggs S, Mirshams RA, Cooper WL, Park SY, Kim MJ, Hartley C, Lu H (2014) Characterization of the grain-level mechanical behavior of Eglin sand by nanoindentation. Exp Mech 54(5):871–884. doi:10.1007/s11340-013-9845-z

Hu Z, Du Y, Luo H, Zhong B, Lu H (2014) Internal deformation measurement and force chain characterization of mason sand under confined compression using incremental digital volume correlation. Exp Mech 54(9):1575–1586. doi:10.1007/s11340-014-9915-x

Luo H, Du Y, Hu Z, Lu H (2015) High-strain-rate compressive behavior of glass bead under confinement. Exp Mech 55(5):935–950. doi:10.1007/s11340-015-9995-2

Canepa P, Tan K, Du Y, Lu H, Chabal YJ, Thonhauser T (2015) Structural, elastic, thermal, and electronic responses of small-molecule-loaded metal–organic framework materials. J Mater Chem A 3(3):986–995. doi:10.1039/C4TA03968H

Liu Y, Wang B, Yoshino M, Roy S, Lu H, Komanduri R (2005) Combined numerical simulation and nanoindentation for determining mechanical properties of single crystal copper at mesoscale. J Mech Phys Solids 53(12):2718–2741. doi:10.1016/j.jmps.2005.07.003

Liu Y, Varghese S, Ma J, Yoshino M, Lu H, Komanduri R (2008) Orientation effects in nanoindentation of single crystal copper. Int J Plast 24(11):1990–2015. doi:10.1016/j.ijplas.2008.02.009

Briscoe BJ, Fiori L, Pelillo E (1998) Nano-indentation of polymeric surfaces. J Phys D Appl Phys 31(19):2395–2405. doi:10.1088/0022-3727/31/19/006

Van Landingham MR (2003) Review of instrumented indentation. National Institution of Standards and Technology, Gaithersburg, MD

Lu H, Wang B, Ma J, Huang G, Viswanathan H (2003) Measurement of creep compliance of solid polymers by nanoindentation. Mech Time-Depend Mater 7(3–4):189–207. doi:10.1023/B:MTDM.0000007217.07156.9b

Huang G, Wang B, Lu H (2004) Measurement of viscoelastic function of polymers in the frequency-domain using nanoindentation. Mech Time-Depend Mater 8(4):345–364. doi:10.1007/s11043-004-0440-7

Huang G, Lu H (2007) Measurement of two independent viscoelastic functions by nanoindentation. Exp Mech 47(1):87–98. doi:10.1007/s11340-006-8277-4

Cheng L, Xia X, Yu W, Scriven LE, Gerberich WW (2000) Flat-punch indentation of viscoelastic material. J Polym Sci B Polym Phys 38(1):10–22. doi:10.1002/(SICI)1099-0488(20000101)38:1<10::AID-POLB2>3.0.CO;2-6

Lu H, Huang G, Wang F (2007) Measurements of viscoelastic properties of polymers using flat punch indenter. Conf Proc Soc Exp Mech 2:697–704

Cheng YT, Cheng CM (2005) General relationship between contact stiffness, contact depth, and mechanical properties for indentation in linear viscoelastic solids using axisymmetric indenters of arbitrary profiles. Appl Phys Lett 87(11):111914. doi:10.1063/1.2048820

Cheng YT, Cheng CM, Ni W (2006) Methods of obtaining instantaneous modulus of viscoelastic solids using displacement-controlled instrumented indentation with axisymmetric indenters of arbitrary smooth profiles. Mater Sci Eng A 423(1):2–7. doi:10.1016/j.msea.2005.09.134

Cao Y (2007) Determination of the creep exponent of a power-law creep solid using indentation tests. Mech Time-Depend Mater 11(2):159–172. doi:10.1007/s11043-007-9033-6

Kucuk Y, Mollamahmutoglu C, Wang Y, Lu H (2013) Nonlinearly viscoelastic nanoindentation of PMMA under a spherical tip. Exp Mech 53(5):731–742. doi:10.1007/s11340-012-9695-0

Lu H, Huang G, Wang B, Mamedov A, Gupta S (2006) Characterization of the linear viscoelastic behavior of single wall carbon nanotube/polyelectrolyte multilayer nanocomposite film using nanoindentation. Thin Solid Films 500(1):197–202. doi:10.1016/j.tsf.2005.11.051

Francius G, Hemmerle J, Ball V, Lavalle P, Picart C, Voegel JC, Schaaf P, Senger B (2007) Stiffening of soft polyelectrolyte architectures by multilayer capping evidenced by viscoelastic analysis of AFM indentation measurements. J Phys Chem C 111(23):8299–8306. doi:10.1021/jp070435+

Sadr A, Shimada Y, Lu H, Tagami J (2009) The viscoelastic behavior of dental adhesives: a nanoindentation study. Dent Mater 25(1):13–19. doi:10.1016/j.dental.2008.05.001

Huang G, Daphalapurkar NP, Gan RZ, Lu H (2008) A method for measuring linearly viscoelastic properties of human tympanic membrane using nanoindentation. J Biomech Eng 130(1):014501. doi:10.1115/1.2838034

Daphalapurkar NP, Dai C, Gan RZ, Lu H (2009) Characterization of the linearly viscoelastic behavior of human tympanic membrane by nanoindentation. J Mech Behav Mater 2(1):82–92. doi:10.1016/j.jmbbm.2008.05.008

Huang X, Pelegri AA (2006) Mechanical characterization of thin film materials with nanoindentation measurements and FE analysis. J Compos Mater 40(15):1393–1407. doi:10.1177/0021998305059728

Florentin E, Lubineau G (2010) Identification of the parameters of an elastic material model using the constitutive equation gap method. Compu Mech 46(4):521–531. doi:10.1007/s00466-010-0496-y

Moussawi A, Lubineau G, Florentin E, Blaysat B (2013) The constitutive compatibility method for identification of material parameters based on full-field measurements. Comput Methods Appl Mech Engrg 265:1–14. doi:10.1016/j.cma.2013.06.003

Sutton MA, Wolters WJ, Peters WH, Ranson WF, McNeill SR (1983) Determination of displacements using an improved digital correlation method. Image Vision Comput 1:133–139. doi:10.1016/0262-8856(83)90064-1

Lu H, Cary P (2000) Deformation measurements by digital image correlation: Implementation of a second-order displacement gradient. Exp Mech 40:393–400. doi:10.1007/BF02326485

Sneddon IN (1965) The relation between load and penetration in the axisymmetric Boussinesq problem for a punch of arbitrary profile. Int J Eng Sci 3(1):47–57. doi:10.1016/0020-7225(65)90019-4

Huang G, Lu H (2006) Measurement of Young’s relaxation modulus using nanoindentation. Mech Time-Depend Mater 10(3):229–243. doi:10.1007/s11043-006-9020-3

Emri I, Tschoegl NW (1993) Generating line spectra from experimental responses. Part I: relaxation modulus and creep compliance. Rheol Acta 32(3):311–321. doi:10.1007/BF00434195

Tschoegl NW, Emri I (1992) Generating line spectra from experimental responses III. Interconversion between relaxation and retardation behavior. Int J Polym Mater 18(1–2):117–127. doi:10.1080/00914039208034818

Luk-Cyr J, Crochon T, Li C, Levesque M (2013) Interconversion of linearly viscoelastic material functions expressed as Prony series: a closure. Mech Time-Depend Mater 17(1):53–82. doi:10.1007/s11043-012-9176-y

Baumgaertel M, Winter HH (1989) Determination of discrete relaxation and retardation time spectra from dynamic mechanical data. Rheol Acta 28(6):511–519. doi:10.1007/BF01332922

Luo H, Lu G, Roy S, Lu H (2013) Characterization of the viscoelastic behavior of bismaleimide resin before and after exposure to high temperatures. Mech Time-Depend Mater 17(3):369–399. doi:10.1007/s11043-012-9189-6

Luo H, Zhang Y, Wang B, Lu H (2010) Characterization of the compressive behavior of glass fiber reinforced polyurethane foam at different strain rates. J Offshore Mech Arct Eng 132(2):021301. doi:10.1115/1.4000396

Knauss WG, Zhao J (2007) Improved relaxation time coverage in ramp-strain histories. Mech Time-Depend Mater 11(3–4):199–216. doi:10.1007/s11043-007-9035-4

Kong JW, Kim JK, Yuen MM (2003) Warpage in plastic packages: effects of process conditions, geometry and materials. IEEE Trans Electron Packag Manuf 26(3):245–252. doi:10.1109/TEPM.2003.820806

Yeung DT, Yuen MM (2001) Warpage of plastic IC packages as a function of processing conditions. J Electron Packag 123(3):268–272. doi:10.1115/1.1349421

Lu H, Zhang X, Knauss WG (1997) Uniaxial, shear, and Poisson relaxation and their conversion to bulk relaxation: studies on poly (methyl methacrylate). Polym Eng Sci 37(6):1053–64. doi:10.1002/pen.11750

Constantinides G, Ravi Chandran KS, Ulm FJ, Van Vilet KJ (2006) Grid indentation analysis of composite microstructure and mechanics: Principles and validation. Mater Sci Eng A 430(1):189–202. doi:10.1016/j.msea.2006.05.125

Ulm FJ, Vandamme M, Bobko C, Ortega JA (2007) Statistical indentation techniques for hydrated nanocomposites: concrete, bone, and shale. J Am Ceram Soc 90(9):2677–2692. doi:10.1111/j.1551-2916.2007.02012.x

Sorelli L, Constantinides G, Ulm FJ, Toutlemonde F (2008) The nano-mechanical signature of ultra high performance concrete by statistical nanoindentation techniques. Cem Concr Res 38(12):1447–1456. doi:10.1016/j.cemconres.2008.09.002

Zhu W, Hughes JJ, Bicanic N, Pearce CJ (2007) Nanoindentation mapping of mechanical properties of cement paste and natural rocks. Mater Charact 58(11):1189–1198. doi:10.1016/j.matchar.2007.05.018

Chen J, Bull SJ (2006) On the relationship between plastic zone radius and maximum depth during nanoindentation. Surf Coat Technol 201(7):4289–4293. doi:10.1016/j.surfcoat.2006.08.099

Chen X (2010) Computational Modeling of Indentation. In: Oyen M (ed) Handbook of Nanoindentation with Biological Applications, Pan Stanford Publishing, ISBN: 978–9814241892

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH Image to ImageJ: 25 years of image analysis. Nat Methods 9(7):671–675. doi:10.1038/nmeth.2089

Acknowledgments

We acknowledge the support of Texas Instruments, NSF under ECCS-1307997, and DOE under NEUP 09–818. Lu also thanks the Louis A. Beecherl Jr., Chair for additional support. We thank Dr. Dani Z. Fadda for editing the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, T., Du, Y., Luo, H. et al. Measurement of Temperature-Dependent Young’s Modulus at a Strain Rate for a Molding Compound by Nanoindentation. Exp Mech 57, 1135–1147 (2017). https://doi.org/10.1007/s11340-016-0205-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-016-0205-7