Abstract

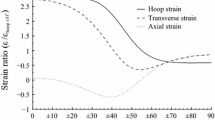

The objective of this study is to measure the axial, circumferential, shear and radial residual stress distributions in three thick-walled glass fibre reinforced plastic (GFRP) filament-wound pipes, two of which are layered. The measurement of residual stresses was carried out using a recently published layer removal method which overcomes the limitations of previous techniques and can be applied to layered anisotropic pipes of any wall thickness. Layers of approximately 0.3 mm thickness were incrementally ground from the outer surface of the pipes. The resulting strains were measured on the inner surfaces. A least-squares polynomial was fitted to each measured data set, and used to calculate the corresponding stress distributions. All of the resulting axial, hoop and shear stress distributions adhere to the requirement of self-equilibrium and the radial stress distributions all vanish to zero at the inner and outer surfaces. The radial stresses of the layered pipes showed a tendency to have two peaks, one for each layer, a consequence of the two-stage manufacturing process of these pipes. The measured axial and hoop stresses of all three pipes were similar at the inner surfaces despite significant differences in the stiffnesses in the principal directions arising from different wind angles.

Similar content being viewed by others

References

Tarnopol’skii Yu M, Portnov GG, Spridzans Yu B (1972) Compensation of thermal stresses in glass-fiber-reinforced plastic articles by the layerwise winding method. Polym Mech 8(4):553–557

Gong H, Wu Y, Liao K (2009) Research on residual stress measurement technology of aluminum alloy plate based on modified layer removal method. In: 1st international conference on information science and engineering, ICISE, pp 3839–3842

Yang F, Wang Y, Jiang J (2010) Residual stress profile in high carbon rods measured by layer removal technique. Cailiao Kexue yu Gongyi/Mater Sci Technol 18(4):579–583

Cheng W, Finnie I (2007) Residual stress measurement and the slitting method. Springer

Prime MB (1999) Residual stress measurement by successive extension of a slot: the crack compliance method. Appl Mech Rev 52(2):75–96

Prime MB (1999) Measuring residual stress and the resulting stress intensity factor in compact tension specimens. Fatigue Fract Eng Mater Struct 22(3):195–204

Prime MB, Hill MR (2004) Measurement of fiber-scale residual stress variation in a metal-matrix composite. J Compos Mater 38(23):2079–2095

DeWald AT, Hill MR (2011) Measurement of bulk residual stress distributions in thick-section components using the contour method. In: Conference proceedings of the society for experimental mechanics series, vol 8, pp 29–31

Pagliaro P, Prime MB, Swenson H, Zuccarello B (2010) Measuring multiple residual-stress components using the Contour method and multiple cuts. Exper Mech 50(2):187–194

Flaman MT, Manning BH (1985) Determination of residual-stress variation with depth by the hole-drilling method. Exp Mech 25(3):205–207

Sicot O, Gong XL, Cherouat A, Lu J (2004) Influence of experimental parameters on determination of residual stress using the incremental hole-drilling method. Compos Sci Technol 64(2):171–180

Sachs G (1927) The determination of residual stresses in rods and tubes. Zeitschrift für Metallkinde 19:352–357

Stacey A, Webster GA (1988) Determination of residual stress distributions in autofrettaged tubing. Int J Pressure Vessels Pip 31(3):205–220

Kim JW, Lee DG (2007) Measurement of residual stresses in thick composite cylinders by the radial-cut-cylinder-bending method. Compos Struct 77(4):444–456

Seif MA, Short SR (2002) Determination of residual stresses in thin-walled composite cylinders. Exp Tech 26(2):43–46

Seif MA, Khashaba UA, Rojas-oviedo R (2007) Residual stress measurements in CFRE and GFRE composite missile shells. Compos Struct 79(2):261–269

Akbari S, Taheri-Behrooz F, Shokrieh MM (2013) Slitting measurement of residual hoop stresses through the wall-thickness of a filament wound composite ring. Exp Mech:1–10

Botros BM (1960) Residual stresses in cold ironed tubes. Int J Mech Sci 2(3):195–205

Mack DR (1962) Measurement of residual stress in disks from turbine-rotor forgings - Investigation reveals that both the sachs turning-down method and the concentric-ring method provide reliable measurements of tangential residual stress in a steel disk at the bore hole. Exp Mech 2(5):155–158

Chen J, Terasaki T, Akiyama T, Kishitake K (2000) New concept of equivalent inherent strain for measuring axisymmetric residual stresses. J Manuf Sci Eng Trans ASME 122(2):304–309

Olson WA, Bert CW (1966) Analysis of residual stresses in bars and tubes of cylindrically orthotropic materials - Paper presents equations for calculating residual stresses from surface-strain data measured after successive borings in a bar or tube made of a cylindrically orthotropic material. Exp Mech 6(9):451–457

Voyiadjis GZ, Kiousis PD, Hartley CS (1985) Analysis of residual stresses in cylindrically anisotropic materials. Exp Mech 25(2):145–147

Voyiadjis GZ, Hartley CS (1987) Residual-stress determination of concentric layers of cylindrically orthotropic materials. Exp Mech 27(3):290–297

Carpenter HW, Reid RG, Paskaramoorthy R. (2014) Extension of the layer removal technique for the measurement of residual stresses in layered anisotropic cylinders. Inte J Mech Mater Des:1–12

Herakovich CT (1998) Mechanics of fibrous composites. Wiley

Holman JP (2012) Experimental methods for engineers, 8th edn. McGraw-Hill

Prime MB, Hill MR (2006) Uncertainty analysis, model error, and order selection for series-expanded, residual stress inverse solutions. J Eng Mater Technol 128(2):175–185

ASM International (1995) Engineered materials handbook - desk edition. Materials Park, Ohio

Acknowledgments

The support of the DST/NRF Centre of Excellence in Strong Materials (CoE-SM) towards this research is hereby acknowledged. Opinions expressed and conclusions arrived at, are those of the authors and are not necessarily to be attributed to the CoE-SM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Carpenter, H.W., Reid, R.G. & Paskaramoorthy, R. Measurement of the Distribution of Residual Stresses in Layered Thick-Walled GFRP Pipes. Exp Mech 54, 1627–1638 (2014). https://doi.org/10.1007/s11340-014-9934-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-014-9934-7