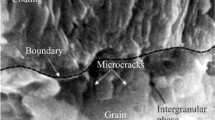

Results are given for modeling the stress-strained state of an oxide-carbide surface layer with jet-abrasive treatment using a developed research method of system combination. Stress and strain are analyzed in Al2O3–MgO system ceramic under action of different loads. The possibility is determined of using the dependences revealed for constructing a model of ceramic surface formation during jet-abrasive treatment.

Similar content being viewed by others

References

V. V. Kuzin, N. R Portnoi, S. Yu. Federov, et al., “Effect of air-abrasive treatment on operating properties of objects mad of oxide-carbide ceramic,” Novye Ogneupory, No. 9, 62 – 67 (2015).

V. V. Kuzin, N. R Portnoi, S. Yu. Federov, et al., “Analysis of the reliability of ceramic components after hydroabrasive treatment, Novye Ogneupory, No. 11, 63 – 68 (2015).

A. A. El-Domiaty and A. A. Abdel-Rahman, “Fracture mechanics based on model of abrasive waterjet cutting for brittle materials,” Int. J. Adv. Manuf. Technol., 13, 181 – 192 (1997).

M. Wakuda, Y. Yamauchi, and S. Kanzaki, “Material response to particle impact during abrasive jet machining of alumina ceramics,” J. Mat. Process. Technol., 132, 177 – 183 (2003).

S. N. Grigor’ev, V. V. Kuzin, S. Yu. Fedorov, et al., “Morphology of the surface of a high density ceramic after hydroabrasive machining,” Refract. Indust. Ceram., 56(2), 164 – 167 (2015).

S. N. Grigor’ev, V. V. Kuzin, S. Yu. Fedorov, et al., “Model of the formation of the profile of a cut in the hydroabrasive machining of a high-density ceramic,” Refract. Indust. Ceram., 56(1), 48 – 53 (2015).

L. Chen, E. Siores, and W. C. K. Wong, “Optimising abrasive waterjet cutting of ceramic materials,” J. Mat. Proc. Technol., 74, 251 – 254 (1998).

J. Wang, “The effect of jet impact angle on the cutting performance in AWJ machining of alumina ceramics,” Key Eng. Mater. 238/239, 117 – 122 (2003).

R. M. Miranda and L. Quintino, “Microstructural study of material removal mechanisms observed in abrasive waterjet cutting of calcareous stones,” Materials Characterization, 54, 370 – 377 (2005).

M.Wakuda, Y. Yamauchi, and S. Kanzaki, “Effect of workpiece properties on machinability in abrasive jet machining of ceramic materials,” Precision Engineering, 26, 193 – 198 (2002).

D. S. Srinivasu, D. A. Axinte, P. H. Shipway, et al., “Influence of kinematic operating parameters on kerf geometry in abrasive waterjet machining of silicon carbide ceramics,” Int. J. Machine Tools & Manufacture, 49, 1077 – 1088 (2009).

J. Wang, “A new model for predicting the depth of cut in abrasive waterjet contouring of alumina ceramics,” J. Mat. Process. Technol., 209, 2314 – 2320 (2009).

H. Liu, J. Wang, N. Kelson, and R. Brown, “CFD simulation and mathematical models of the abrasive waterjet characteristics,” J. Mat. Process. Technol. 153/154, 488 – 493 (2004).

A. Saxena and S. Paul, “Numerical modelling of kerf geometry in abrasive water jet machining,” Int. J. Abrasive Technology, No. 1, 208 – 230 (2007).

M. Junkar, B. Jurisevic, M. Fajdiga, et al., “Finite element analysis of single-particle impact in abrasive water jet machining,” Int. J. Impact Eng., 32, 1095 – 1112 (2006).

R. T. Deam, E. Lemma, and D. H. Ahmed, “Modelling of the abrasive water jet cutting process,”Wear, 257, 877 – 891 (200).

H. Liu, J. Wang, N. Kelson, and R. J. Brown, “A study of abrasive waterjet characteristics by CFD simulation,” J. Mat. Process. Technol., 153/154, 488 – 493 (2004).

V. V. Kuzin, E. D. Korshunova, N. R. Portnoi, et al., “Numerical modeling of the stress-strain state of a surface layer of oxide-carbide ceramic with jet-abrasive treatment,” Novye Ogneupory, No. 12, 51 – 55 (2015).

V. V. Kuzin, “Microstructural model of ceramic cutting plate,” Russ. Eng. Res., 31(5), 479 – 483 (2011).

S. N. Grigor’ev, V. I. Myachenkov, and V. V. Kuzin, “Automated thermal-strength calculations of ceramic cutting plates,” Russ. Eng. Res., 31(11), 1060 – 1066 (2011).

V. Kuzin and S. Grigoriev, “Method of investigation of the stress-strain state of surface layer of machine elements from a sintered nonuniform material,” Appl. Mechan. Mater., 486, 32 – 35 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 2, pp. 56 – 61, February, 2016.

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Fedorov, S.Y. & Portnoi, N.R. Analysis of Oxide-Carbide Ceramic Surface Layer Stress-Strained State with Jet-Abrasive Treatment. Refract Ind Ceram 57, 98–102 (2016). https://doi.org/10.1007/s11148-016-9935-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-016-9935-4