The main tasks of studying molybdenum silicides for use at elevated temperature include development of materials with a melting point Tme ≥ 2000°C, possibly with a low brittle-ductile transition temperature and resistance to high temperature oxidation. The possibility is considered of increasing corrosion resistance of a model alloy consisting of molybdenum solid solution and Mo3Si. The effect of Sc or Nd alloying additives, as well as preliminary high-temperature annealing. i.e., pre-oxidation in order to create a protective oxide layer on the alloy surface of a model alloy, is evaluated. Non-isothermal oxidation of alloys is performed using combined thermogravimetric and differential thermal analysis methods. The phase composition of the scale formed is determined by an X-ray diffraction method. As a result of these studies it is established that preliminary oxidation firing of Mo–Mo3Si–REE (about 3 at.%) alloys at 1100°C for 5–10 min provides conditions for forming a layer of SiO2 and REE molybdates Sc2(MoO4)3 and Nd2Si2O7 at the alloy surface. Oxidation in a dynamic regime for treated alloys in the range 500–850°C proceeds much more slowly than for the initial samples. This can be explained by the difficult access of oxygen to the reaction zone through a protective layer of non-volatile oxides. In addition, preliminary oxidation of Mo–Mo3Si alloyed with Sc or Nd during subsequent oxidation leads to an increase in the transition temperature for the process from the stage of oxide formation to intense MoO3 sublimation.

Similar content being viewed by others

References

M. Krüger, P. Jain, K. S. Kumar, and M. Heilmaier, “Correlation between microstructure and properties of fine grained Mo–Mo3Si–Mo5SiB2 alloys,” Intermetallics, 48, 10–18 (2014).

M. K. Meyer, A. J. Thom, and M. Akinc, “Oxide scale formation and isothermal oxidation behavior of Mo–Si–B intermetallics at 600–1000°C,” Intermetallics, 7, No. 2, 152–162 (1999).

S. Katrych, A. Grytsiv, A. Bondar, et al., “Structural materials: metal–silicon–boron: On the melting behavior of Mo–Si–B alloys,” J. Alloys and Compounds, 347, No. 1/2, 94–100 (2002).

F. Chu, D. J. Thomas, K. McClellan, et al., “Synthesis and properties of Mo5Si3 single crystals,” Intermetallics, 7, No. 5, 611–620 (1999).

H. Chen, Q. Ma, X. Shao, et al., “Microstructure, mechanical properties and oxidation resistance of Mo5Si3–Al2O3 composite,” Materials Science and Engineering: A, 592, 12–18 (2014).

M. Samadzadeh, C. Oprea, H. Karimi Sharif, and T. Troczynski, “Comparative studies of the oxidation of MoSi2 based materials: High-temperature oxidation (1000–1600°C),” International J. Refractory Metals and Hard Materials, 69, 31–39 (2017).

Y. Q. Liu, G. Shao, and P. Tsakiropoulos, “On the oxidation behaviour of MoSi2,” Intermetallics, 9, No. 2, 125–136 (2001).

C. D. Wirkus and D. R. Wilder, “High-temperature oxidation of molybdenum disilicide,” J. American Ceramic Society, 49, No. 4, 173–177 (1966).

D. A. Berztiss, R. R. Cerchiara, E. A. Gulbransen, et al., “Oxidation of MoSi2 and comparison with other silicide materials,” Materials Science and Engineering: A, 155, No. 1/2, 165–181 (1992).

T. C. Chou and T. G. Nieh, “New observations of MoSi2 pest at 500°C,” Scripta Metallurgica et Materialia, 26, No. 10, 1637– 1642 (1992).

I. Rosales and J. H. Schneibel, “Stoichiometry and mechanical properties of Mo3Si,” Intermetallics, 8, No. 8, 885–889 (2000).

I. Rosales, H. Martinez, D. Bahena, et al., “Oxidation performance of Mo3Si with Al additions,” Corrosion Science, 51, No. 3, 534–538 (2009).

S. Ochiai, “Improvement of the oxidation-proof property and the scale structure of Mo3Si intermetallic alloy through the addition of chromium and aluminum elements,” Intermetallics, 14, No. 10/11, 1351–1357 (2006).

M .F. Ashby, F. J. Blunt, and M. Bannister, “Flow characteristics of highly constrained metal wires,” Acta Metallurgica, 37, No. 7, 1847–1857 (1989).

D. M .Berczik, USA Patent 5595616, МPК6 C22C32/0047. Method of Improving Molybdenum Alloy Oxidation Resistance and Molybdenum Alloy Preparation Method, Claim 07.07.1995; Publ. 01.21.1997, Bull. No. 19.

A. B. Gokhale and G. J. Abbaschian, “The Mo–Si (Molybdenum–Silicon) system,” J. Phase Equilibria, 12, No. 4, 493–498 (1991).

S. Burk, B. Gorr, M. Krüger, et al., “Oxidation behavior of Mo–Si–B–(X) alloys: Macro- and microalloying (X = Cr, Zr, La2O3),” JOM, 63, No. 12, 32–36 (2011).

M. Yu. Belomytsev, M. S. Evseev, D. A. Kozlov, et al., “Heat-resistant composite metal-intermetallic based on NiAl,” Izv. Vuz. Tsvet, Met., No. 6, 68–72 (2007).

S. Paswan, R. Mitra, and S. K. Roy, “Oxidation behaviour of the Mo–Si–B and Mo–Si–B–Al alloys in the temperature range of 700–1300°C,” Intermetallics, 15, No. 9, 1217–1227 (2007).

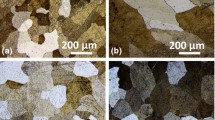

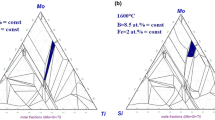

L. Yu. Udoeva, V. M. Chumarev, A. V. Larionov, et al., “Effect of rare earth elements on structure and phase composition of in-situ composites Mo–Si–X (X = Sc, Y, Nd),” Perspekt. Materialy, No. 7, 24–33 (2017).

V. M. Chumarev, R. I. Gulyaeva, L. Yu. Udoeva, et al., “Oxidation of Moss –Mo3Si alloys containing Sc and Nd,” in: XXI Mendeleev Meeting for General and Applied Chemistry: Coll. Theses in 6 Vol., Vol 3 (2019).

NETZSCH Proteus Software. Thermal Analysis, Version 4.8.3.

A. Roine, HSC Chemistry 6.0 User’s Guide. Chemical Reaction and Equilibrium Software with Extensive Thermochemical Database and Flowsheet Simulation [Electronic Source]. Pori: Outotec Research Oy. (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 64, No. 8, pp. 77–82, August, 2020.

Rights and permissions

About this article

Cite this article

Udoeva, L.Y., Pikulin, K.V., Gulyaeva, R.I. et al. Effect of Preliminary Firing on Oxidation of Mo–Mo3Si Alloyed with Sc or Nd. Metallurgist 64, 822–829 (2020). https://doi.org/10.1007/s11015-020-01059-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-020-01059-9