Abstract

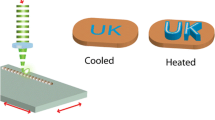

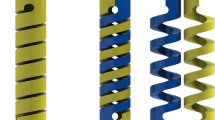

Selective laser melting has been used to build high aspect ratio, three-dimensional NiTi micro-electro-mechanical components. Cantilever beams manufactured in this way have been two-way trained and actuated by ohmic heating demonstrating the suitability of the process for applications in micro-electromechanical technologies. The influence of laser dwell time and raster pitch on the density of NiTi shape memory alloy parts and the resolvable feature sizes achievable are discussed. The shape memory effect properties of solid parts produced by selective laser melting are also reported in contrast to those properties exhibited by NiTi alloys resulting from other processes.

Similar content being viewed by others

References

Agarwala, M., Bourell, D., Beaman, J., Marcus, H., Barlow, J.: Rapid Prototyping 1, 26 (1995)

Beaman ,J.J., Barlow, J.W., Bourell, D.L., Crawford, R.H., Marcus, H.L., Mcalea, K.P.: Solid Freeform Fabrication: A New Direction in Manufacturing. Kluwer Academic Publishers (1997)

Chalker, P.R., Clare, A.T., Davies, S., Sutcliffe, C.J., Tsopanos, S.: Selective laser melting of high aspect ratio 3D nickel - Titanium structures for MEMS applications. Mater. Res. Soc. Symp. Proc. 890, 93 (2006)

Eggeler, G., Khalil-Allafi, J., Gollerthan, S., Somsen, C., Schmahl, W., Sheptyakov, D.: On the effect of aging on martensitic transformations in Ni-rich NiTi shape memory alloys. Smart Mater. Struct. 14, S186 (2005)

Fu, Y., Du, H., Huang, W., Zhang, S., Hu, M.:TiNi-based thin films in MEMS applications: A review; Source: Sensors and Actuators, A: Physical. 112(2/3), 395–408 (2004). (Fu, Yongqing: Sch. of Mech./Production Engineering, Nanyang Technological University).

He, J.-J., Zhong, M.-L.; Liu, W.-J.: Materials research based on laser direct manufacturing technology (2006)

Lu, L., Fuh, J. and Wong, Y.S.: Laser-Induced Materials and processes for Rapid Prototyping, Kluwer Academic Publishers (2001).

Mihalcz, I.: Fundamental characteristics and design method for nickel-titianium shape memory alloys. Periodica Polytechnica Ser. Mech. Eng. 45(1), 75–86 (2000)

Miyazaki, S., Ishida, A.: Mechanical properties of Ti-Ni shape memory thin films formed by sputtering. Mater. Sci. Eng. A273–A275, 106 (1999)

Morgan, R., Sutcliffe, C.J., O’Neill, W.: Density analysis of direct metal laser re-melted 316L stainless steel cubic primitives. J. Mater. Sci. 39(4), 1195 (2004)

NDC, Material Data Sheet, Nitinol SE508 (2006)

Venuvinod, P.K., Ma W: Rapid Prototyping-Laser Based and Other Technologies. Kluwer Academic Publishers, OPTICS (2004)

Tsopanos S., C. J. Sutcliffe and I. Owen, Proc. Fifth Int. Conf. on Enhanced, Compact and Ultra-Compact Heat Exchangers: Science, Engineering and Technology, CHE (2005)

Yang, X. C., Li, H. S., Lei, J. B., Wang, Y. S.: DPIV method of measurement of powder stream of co-axial feeding for laser manufacturing. Proceedings of SPIE - The International Society for Optical Engineering: Lasers in Material Processing and Manufacturing II, 5629, 93–102 (2005). (Yang, Xi-Chen: Laser Processing Center, Tianjin Polytechnic University).

Acknowledgements

The authors gratefully acknowledge the financial support of the Engineering and Physical Sciences Research Council under the pilot project EP/C519795/1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Clare, A.T., Chalker, P.R., Davies, S. et al. Selective laser melting of high aspect ratio 3D nickel–titanium structures two way trained for MEMS applications. Int J Mech Mater Des 4, 181–187 (2008). https://doi.org/10.1007/s10999-007-9032-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-007-9032-4