Abstract

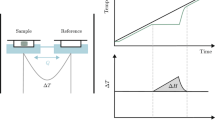

The objective of this study is to increase the thermal diffusivity of Al–Si–Mg alloys by heat treatment and demonstrate the effect of the eutectic phase distribution on thermal conductivity of Al–Mg–Si alloys. Two types of Al–Si–Mg (Al–0.2Si–0.4Mg and Al–6.5Si–0.4Mg) alloys used in this study were prepared through atmospheric gravity casting. Solid solution treatment was performed at 535 °C for 4–10 h and then quenched in warm water of 80 °C temperature. Artificial aging of specimens was performed at 180 °C for 5 h. After aging treatment, the changes of microstructures due to heat treatment were examined by using optical microscopy. Differential scanning calorimeter analyzed phase transform during the heat treatment. Variations of thermal diffusivity according to the microstructures were investigated by using a laser flash apparatus. Precipitation of Mg2Si and Si phases increased the thermal diffusivity after aging treatment. Moreover, thermal diffusivity of the Al–6.5Si–0.4Mg alloys also increased with increasing solid solution treatment time due to spheroidization of eutectic Si.

Similar content being viewed by others

References

Liu L, Kang S. The solidification process of Al–Mg–Si alloys. J Mater Sci. 1997;2:1443–7.

Li C, Wu Y, Li H, Liu X. Microstructural formation in hypereutectic Al–Mg–2Si with extra Si. J Alloys Compd. 2009;477:212–6. https://doi.org/10.1016/j.jallcom.2008.10.061.

Birol Y. Optimization of homogenization for a low alloyed Al–Mg–Si alloy. Mater Charact. 2013;80:69–75. https://doi.org/10.1016/j.matchar.2013.03.013.

Grieb B. Ternary alloys: a comprehensive compendium of evaluated constitutional data and phase diagram. Adv Mater. 1991;4:59–63.

Eskin DG, Massardier V, Merle P. Study of high-temperature precipitation in Al–Mg–Si alloys with an excess of silicon. J Mater Sci. 1999;34:811–20. https://doi.org/10.1023/A:1004585216084.

Ceresara S, Russo EDI, Fiorini P, Giarda A. Effect of Si excess on the ageing behaviour of Al–Mg–2Si0.8% alloy. Mater Sci Eng. 1969;5(4):220–7.

Doan LC, Nakai K, Matsuura Y, Kobayashi S, Ohmori Y. Effects of excess Mg and Si on the isothermal ageing behaviours in the Al–Mg–2Si alloys. Mater Trans. 2002;43:1371–80. https://doi.org/10.2320/matertrans.43.1371.

Zhen L, Fei WD, Kang SB, Kim HW. Precipitation behaviour of Al–Mg–Si alloys with high silicon content. J Mater Sci. 1997;32:1895–902. https://doi.org/10.1023/A:1018569226499.

Gupta AK, Lloyd DJ, Court SA. Precipitation hardening in Al–Mg–Si alloys with and without excess Si. Mater Sci Eng A. 2001;316:11–7. https://doi.org/10.1016/S0921-5093(01)01247-3.

Davis JR. Alloying: understanding the basics. ASM Int. 2001. https://doi.org/10.1361/autb2001.

Tritt TM. Thermal conductivity: theory, properties, and applications. New York: Kluwer Academic/Plenum; 2004.

Kuijpers NCW, Vermolen FJ, Vuik C, Koenis PTG, Nilsen KE, van der Zwaag S. The dependence of the β-Al–Fe–Si to α-Al(FeMn)Si transformation kinetics in Al–Mg–Si alloys on the alloying elements. Mater Sci Eng A. 2005;394:9–19. https://doi.org/10.1016/j.msea.2004.09.073.

Rosenbaum HS, Turnbull D. Metallographic investigation of precipitation of silicon from aluminum. Acta Metall. 1959;7:664–74. https://doi.org/10.1016/0001-6160(59)90143-9.

Shackelford JF. Introduction of materials science for engineers; instructor’s manual. 3rd ed. London: Publishing Company; 1992.

Tye RP. Thermal conductivity, vol. 1. London: Academic Press; 1969.

Muojekwu CA, Samarasekera IV, Brimacombe JK. Heat transfer and microstructure during the early stages of metal solidification. Metall Mater Trans B. 1995;26:361–82. https://doi.org/10.1007/BF02660979.

Brandt R, Neuer G. Electrical resistivity and thermal conductivity of pure aluminum and aluminum alloys up to and above the melting temperature. Int J Thermophys. 2007;28:1429–46. https://doi.org/10.1007/s10765-006-0144-0.

Mondolfo LF. Aluminum alloys: structure and properties. Amsterdam: Elsevier; 2013.

Cengel YA, Ghajar AJ. Heat and mass transfer. Berlin: Springer; 2011. https://doi.org/10.1017/CBO9781107415324.004.

Afify N, Gaber A, Mostafa MS, Abbady G. Influence of Si concentration on the precipitation in Al–1at.%Mg alloy. J Alloys Compd. 2008;462:80–7. https://doi.org/10.1016/j.jallcom.2007.08.043.

Gaber A, Afify N, Mostafa MS, Abbady G. Effect of heat treatment on the precipitation in Al–1at.%Mg–x at.% Si (x = 0.6, 1.0 and 1.6) alloys. J Alloys Compd. 2009;477:295–300. https://doi.org/10.1016/j.jallcom.2008.11.009.

Lasagni F, Mingler B, Dumont M, Degischer HP. Precipitation kinetics of Si in aluminium alloys. Mater Sci Eng A. 2008;480:383–91. https://doi.org/10.1016/j.msea.2007.07.008.

Kim YM, Choi SW, Hong SK. The behavior of thermal diffusivity change according to the heat treatment in Al–Si binary system. J Alloys Compd. 2016;687:54–8. https://doi.org/10.1016/j.jallcom.2016.06.080.

Choi SW, Cho HS, Kumai S. Influence of precipitation on the coefficient of thermal expansion of Al–Si–Mg–Cu–(Ti) alloys. J Alloys Compd. 2016;655:6–10. https://doi.org/10.1016/j.jallcom.2015.09.207.

John H. Aluminum: properties and physical metallurgy. Cleveland: ASM International; 2005.

Brown M, Gallagher P. Handbook of thermal analysis and calorimetry, volume 5 recent advances, techniques and applications. Amsterdam: Elsevier; 2008.

Starink MJ. The analysis of Al-based alloys by calorimetry: quantitative analysis of reactions and reaction kinetics. Int Mater Rev. 2004;49:191–226. https://doi.org/10.1179/095066004225010532.

Choi S-W, Kim Y-M, Kim Y-C. Influence of precipitation on thermal diffusivity of Al-6Si-0.4Mg-0.9Cu-(Ti) alloys. J Alloys Compd. 2019;775:132–7. https://doi.org/10.1016/j.jallcom.2018.10.068.

Peres MD, Siqueira CA, Garcia A. Macrostructural and microstructural development in Al–Si alloys directionally solidified under unsteady-state conditions. J Alloys Compd. 2004;381:168–81. https://doi.org/10.1016/j.jallcom.2004.03.107.

Acknowledgements

This study was supported by a research program on the development of convergent manufacturing technology for IE4-class electric motors funded by the Ministry of Trade, Industry and Energy (MTIE), Republic of Korea.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kim, Ym., Choi, Sw., Kim, Yc. et al. Increasing the thermal diffusivity of Al–Si–Mg alloys by heat treatment. J Therm Anal Calorim 147, 2139–2146 (2022). https://doi.org/10.1007/s10973-021-10646-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10646-0