Abstract

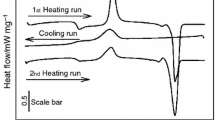

Three series of soft polyvinyl chloride (soft PVC) compounds were prepared at different processing conditions during PVC powder mixing. The processing conditions varied in two different adding procedures of calcium carbonate (CaCO3) powder, two discharge temperatures and two mixing frequencies. The influences of the processing conditions on the glass transition of soft PVC compounds filled with calcium carbonate were extensively investigated by using differential scanning calorimetry (DSC), dynamic mechanical analysis (DMA) and scanning electron microscope (SEM) associated with energy-dispersive X-ray spectroscopy (EDS). It was found that, under the combinative conditions of addition of CaCO3 powder using the one-step procedure instead of two-step procedure, increase of discharge temperature or use of higher mixing frequency, the glass transition of plasticized PVC component could shift to lower temperatures for soft PVC compounds. Under the same formulas, the one-step procedure was confirmed to be preferred, since two separated glass transitions were detected in DSC measurements of the samples prepared by the two-step procedure, where the higher glass transition corresponded to the less plasticized PVC component due to worse mixing efficiency. This finding is quite helpful for the preparation of soft PVC compounds with lower glass transition temperatures.

Similar content being viewed by others

References

Daniels PH (2009) A brief overview of theories of PVC plasticization and methods used to evaluate PVC-plasticizer interaction. J Vinyl Addit Technol 15:219–223

Endo K (2002) Synthesis and structure of poly(vinyl chloride). Prog Polym Sci 27:2021–2054

Saeki Y, Emura T (2002) Technical progresses for PVC production. Prog Polym Sci 27:2055–2131

Sadat-Shojai M, Bakhshandeh GR (2011) Recycling of PVC wastes. Polym Degrad Stab 96:404–415

Chiellini F, Ferri M, Morelli A, Dipaola L, Latini G (2013) Perspectives on alternatives to phthalate plasticized poly(vinyl chloride) in medical devices applications. Prog Polym Sci 38:1067–1088

Chetanachan W, Sookkho D, Sutthitavil W, Chantasatrasamy N, Sinsermsuksakul R (2001) PVC wood: A new look in construction. J Vinyl Addit Technol 7:134–137

Girois S, Schipper PS (2001) Enhanced weatherability of exterior PVC building products. J Vinyl Addit Technol 7:61–66

Wasikiewicz JM, Roohpour N, Paul D, Grahn M, Ateh D, Rehman I, Vadgama P (2008) Polymeric barrier membranes for device packaging, diffusive control and biocompatibility. Appl Surf Sci 255:340–343

Herrero M, Navarro R, Reinecke H, Mijangos C, Grohens Y (2006) Controlled wet-chemical modification and bacterial adhesion on PVC-surfaces. Polym Degrad Stab 91:1915–1918

Hakkarainen M (2003) New PVC materials for medical applications-the release profile of PVC/polycaprolactone-polycarbonate aged in aqueous environments. Polym Degrad Stab 80:451–458

Grossman RF (2008) Handbook of vinyl formulating, 2nd edn. Hoboken, USA

Jamarani R, Erythropel HC, Burkat D, Nicell JA, Leask RL, Maric M (2017) Rheology of green plasticizer/poly(vinyl chloride) blends via time-temperature superposition. Processes 5:43–55

Bocqué M, Voirin C, Lapinte V, Caillol S, Robin JJ (2016) Petro-based and bio-based plasticizers: Chemical structures to plasticizing properties. J Polym Sci Part A: Polym Chem 54:11–33

Kemal I, Whittle A, Burford R, Vodenitcharova T, Hoffman M (2009) Toughening of unmodified polyvinylchloride through the addition of nanoparticulate calcium carbonate. Polymer 50:4066–4079

Jamel MM, Khoshnoud P, Gunashekar S, Abu-Zahra N (2015) Effect of e-glass fibers and phlogopite mica on the mechanical properties and dimensional stability of rigid PVC foams. Polym Plast Technol Eng 54:1560–1570

Fernando NAS, Thomas NL (2007) Effect of precipitated calcium carbonate on the mechanical properties of poly(vinyl chloride). J Vinyl Addit Technol 13:98–102

Cornwell DW, Rodary G (2005) Modification of rigid PVC properties through effective use of synthetic calcium carbonates of controlled morphology and surface character. Plast Rubber Compos 34:105–110

Xie XL, Liu QX, Li RKY, Zhou XP, Zhang QX, Yu ZZ, Mai YW (2004) Rheological and mechanical properties of PVC/CaCO3 nanocomposites prepared by in situ polymerization. Polymer 45:6665–6673

Wales M (1971) Compatibility of plasticizers with poly(vinyl chloride). J Appl Polym Sci 15:293–310

Jia PY, Zhang M, Hu LH, Wang R, Sun C, Zhou YH (2017) Cardanol groups grafted on poly(vinyl chloride)-synthesis, performance and plasticization mechanism. Polymers 9:621–632

Ceccorulli G, Pizzoli M, Scandola M (1987) Composition dependence of the glass transition temperature of polymer-diluent systems: 1. Experimental evidence of a dual behaviour in plasticized PVC. Polymer 28:2077–2080

Scherrenberg R, Reynaers H, Mortensen K, Vlak W, Gondard C (1993) Structural aspects of suspension poly(vinyl chloride). Small-angle neutron scattering of rigid and plasticized suspension PVC. Macromolecules 26:3205–3211

Calò E, Greco A, Maffezzoli A (2011) Effects of diffusion of a naturally-derived plasticizer from soft PVC. Polym Degrad Stab 96:784–789

Brown HR, Musindi GM, Stachurski ZH (1982) Effect of plasticizer concentration and annealing on the structure of PVC. Polymer 23:1508–1514

Kisbényi M (1973) Study of the compatibility of plasticizers with poly(vinyl chloride) by dielectric spectroscopy. J Polym Sci, Polym Symp 42:647–656

Li P, Chen XD, Zeng JB, Gan L, Wang M (2016) Enhancement of the interfacial interaction between poly(vinyl chloride) and zinc oxide modified reduced graphene oxide. RSC Adv 6:5784–5791

Hajibeygi M, Maleki M, Shabanian M, Ducos F, Vahabi H (2018) New polyvinyl chloride (PVC) nanocomposite consisting of aromatic polyamide and chitosan modified ZnO nanoparticles with enhanced thermal stability, low heat release rate and improved mechanical properties. Appl Surf Sci 439:1163–1179

Stuart A, Mccallum MM, Fan D, Lecaptain DJ, Lee CY, Mohanty DK (2010) Poly(vinyl chloride) plasticized with succinate esters: Synthesis and characterization. Polym Bull 65:589–598

Rehm T (1997) The compression set of plasticized PVC. J Vinyl Addit Technol 3:286–291

Fillot LA, Hajji P, Gauthier C, Masenelli-Varlot K (2006) U-PVC gelation level assessment, part 1: Comparison of different techniques. J Vinyl Addit Technol 12:98–107

Wang Y, Wang JJ (1999) Shear yield behavior of calcium carbonate-filled polypropylene. Polym Eng Sci 39:190–198

Zhang L, Chen XH, Li CZ (2005) Mechanical properties of PVC/nano-CaCO3 composites. J Mater Sci 40:2097–2098

Soong SY, Cohen RE, Boyce MC, Mulliken AD (2006) Rate-dependent mechanical deformation behavior of poss-filled and plasticized poly(vinyl chloride). Macromolecules 39:2900–2908

Chen N, Wan CY, Zhang Y, Zhang YX (2004) Effect of nano-CaCO3 on mechanical properties of PVC and PVC/blendex blend. Polym Test 23:169–174

Ari GA, Aydin I (2010) Rheological and fusion behaviors of PVC micro- and nano-composites evaluated from torque rheometer data. J Vinyl Addit Technol 16:223–228

Patil CB, Kapadi UR, Hundiwale DG, Mahulikar PP (2009) Preparation and characterization of poly(vinyl chloride) calcium carbonate nanocomposites via melt intercalation. J Mater Sci 44:3118–3124

Acknowledgement

The Open Research Fund of State Key Laboratory of Polymer Physics and Chemistry, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences (CIAC, CAS) provides the funding support for this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Li, H., Zhang, J., Wei, F. et al. Influences of processing conditions on the glass transition of soft poly(vinyl chloride) compounds filled with calcium carbonate. J Polym Res 28, 138 (2021). https://doi.org/10.1007/s10965-021-02496-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-021-02496-z