Abstract

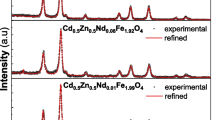

A series of Ni-substituted NixCo(0.5−x)Zn0.5Fe2O4 with x = (0.1, 0.2, 0.3, 0.4) spinel ferrites were prepared by co-precipitation method to investigate the effects of Ni compositional variation in the structural, optical, magnetic and photo-catalytic activity. The thermal decomposition of NixCo(0.5−x)Zn0.5Fe2O4 was investigated by TGA/DTA. XRD results revealed that all the samples were single-phase of cubic spinel with Fd-3m space group. The lattice constant and average particle size decreased simultaneously with the increase in Ni doping amount. TEM and SEM analysis showed the monodispersion and cubic-like nanostructure. Two prominent stretching bands were observed in FT-IR spectra around 400–600 cm−1. These two bands confirmed the spinel structure of the prepared nanoparticles. Raman spectroscopy is used to verify that we have synthesized spinel ferrites and determines their phonon modes. The optical study UV–visible is used to calculate the optical band gap energies. The products exhibited the attractive magnetic properties with high saturation magnetization, which were examined by a vibrating sample magnetometer. On the other part, the photocatalytic activity of our compounds was studied using methylene blue as model organic pollutants, where the results showed that an appropriate amount of Ni dopant could greatly increase the amount of hydroxyl radicals generated by the ferrite nanoparticles, which were responsible for the obvious increase in the photo-catalytic activity.

Similar content being viewed by others

Change history

08 May 2020

A Correction to this paper has been published: https://doi.org/10.1007/s10854-020-03461-0

References

J.P. Singh, R.S. Payal, R.C. Srivastava, H.M. Agrawal, P. Chand, J. Phys. 217, 012108 (2010)

A. Sobhani-Nasab, A. Ziarati, M. Rahimi-Nasrabadi, M. Reza Ganjali, A. Badiei, J. Res. Chem. Intermed. 43, 6155–6165 (2017)

A. Sutka, M. Stingaciu, D. Jakovlevs, G. Mezinskis, Ceram. Int. 40, 2519–2522 (2014)

P.P. Hankare, R.P. Patil, A.V. Jadhav, K.M. Garadkar, R. Sasikala, Appl. Catal. B 107, 333–339 (2011)

S. Tyagi, H.B. Baskey, R.C. Agarwala, V. Agarwala, T.C. Shami, Trans. Indian Inst. Metals 64, 607–614 (2011)

J. Sloczynski, J. Janas, T. Machej, J. Rynkowski, J. Stoch, Appl. Catal. B 24, 45–60 (2000)

A. Ziarati, A. Sobhani-Nasab, M. Rahimi-Nasrabadi, M. Reza Ganjali, A. Badiei, J. Rare Earths 35, 374–381 (2017)

V.F. Puntes, K.M. Krishnan, A.P. Alivisatos, Science 291, 2115 (2001)

M. Pena, J. Fierro, Chem. Rev. 101, 1981–2018 (2001)

P. Ajayan, P. Redlich, M. Ruhle, J. Microsc. 185, 275–282 (1997)

A. Baykal, N. Kasapoglu, Z. Durmus, H. Kavas, M.S. Toprak, Y. Koseoglu, Turk. J.Chem. 33, 33–45 (2009)

X. Wang, G. Yang, Z. Zhang, L. Yan, J. Meng, Dyes Pigments 74, 269–272 (2007)

H. Yang, C. Zhang, X. Shi, H. Hu, X. Du, Y. Fang, Y. Ma, H. Wu, S. Yang, Biomaterials 31, 3667–3673 (2010)

M.A. Ahmed, S.I. El-dek, S.F. Mansour, N. Okasha, Solid State Sci. 13, 1180–1186 (2011)

V. Musat, O. Potecasu, R. Belea, P. Alexandru, Mater. Sci. Eng. B 167, 85–90 (2010)

A.T. Raghavender, N.H. Hong, J. Magn. Magn. Mater. 323, 2145–2147 (2011)

P. Guo, G. Zhang, J.Yu,H. Li, X.S. Zhao, Colloids Surf. A 395, 168–174 (2012)

C. Yao, Q. Zeng, G. Goya, T. Torres, J. Liu, H. Wu, M. Ge, Y. Zeng, Y. Wang, J. Jiang, J. Phys. Chem. C 111, 12274–12278 (2007)

L. Wang, Q. Zhou, F. Li, Physica Status Solidi (B) 241, 377–382 (2004)

A. Kundu, C. Upadhyay, H. Verma, Phys. Lett. A 311, 410–415 (2003)

G. Kianpour, F. Soofivand, M. Badiei, M. Salavati-Niasari, M. Hamadanian, J. Mater. Sci.: Mater. Electron. 28, 14965–14973 (2017)

X. Hu, P. Guan, X. Yan, China Part. 2, 135–137 (2004)

R. Zhang, J. Huang, J. Zhao, Z. Sun, Y. Wang, Energy Fuels 21, 2682–2687 (2007)

B.R. Reddy, T. Sivasankar, M. Sivakumar, V.S. Moholkar, Ultrason. Sonochem. 17, 416–426 (2010)

M.M. Rashad, E.M. Elsayed, M.M. Moharam, R.M. Abou-Shahba, A.E. Saba, J. Alloys Compd. 486, 759–767 (2009)

P. Priyadharsini, A. Pradeep, P.S. Rao, G. Chandrasekaran, Mater. Chem. Phys. 116, 207–213 (2009)

G.S. Shahane, A. Kumar, M. Arora, R.P. Pant, K. Lal, J. Magn. Magn. Mater. 322, 1015–1019 (2010)

H. Malik, A. Mahmood, K. Mahmood, M.Y. Lodhi, M.F. Warsi, I. Shakir, H. Wahab, M. Asghar, M.A. Khan, Ceram. Int. 40, 9439–9444 (2014)

M.A. Khan, M. Sabir, A. Mahmood, M. Asghar, K. Mahmood, M. Afzal Khan, I. Ahmad, M. Sher, M.F. Warsi, J. Magn. Magn. Mater. 360, 188–192 (2014)

V. Pallai, D.O. Shah, J. Magn. Magn. Mater. 163, 243–248 (1996)

M.T. Uddin, Y. Nicolas, C. Olivier, T. Toupance, L. Servant, M.M. Müller, H.-J. Kleebe, J. Ziegler, W. Jaegermann, Inorg. Chem. 51, 7764–7773 (2012)

Y.B. Kannan, R. Saravanan, N. Srinivasan, K. Praveena, K. Sadhana, J. Phys. B. 502, 181–186 (2016)

J.M. Yang, F.S. Yen, J. Alloys Compd. 450, 387–394 (2008)

A. Lassoued, M. Ben hassine, F. Karolak, B. Dkhil, S. Ammar, A. Gadri, J. Mater. Sci.: Mater. Electron. 28, 18857–18864 (2017)

S. Kanagesan, M. Hashim, S. Tamilselvan, N.B. Alitheen, I. Ismail, M. Syazwan, M.M.M. Zuikimi, J. Nanomater. Biostruct. 8, 1601–1610 (2013)

A. Lassoued, M.S. Lassoued, F. Karolak, S. García-Granda, B. Dkhil, S. Ammar, A. Gadri, J. Mater. Sci.: Mater. Electron. 28, 18480–18488 (2017)

A. Lassoued, M.S. Lassoued, B. Dkhil, S. Ammar, A. Gadri, J. Phys. E 97, 328–334 (2018)

B.D. Cullity, Elements of X-ray diffraction Reading (Addison-Wesley, Reading, 1987)

C. Liu, B. Zou, A.J. Rondinone, Z.J. Zhang, J. Am. Chem. Soc. 122, 6263–6267 (2000)

A.A. El-Sayed, Ceram. Int. 28, 363–367 (2002)

A.T. Raghavender, N. Biliškov, Ž Skoko, Mater. Lett. 65, 677–680 (2011)

I. Zalite, G. Heidemane, M. Kodols, J. Grabis, M. Maiorov, Mater. Sci. 18, 1392–1320 (2012)

S. Singhal, J. Singh, S.K. Barthwal, K. Chandra, J. Solid State Chem. 178, 3183–3189 (2005)

A. Pradeep, G. Chandrasekaran, Mater. Lett. 60, 371–374 (2006)

J. Chandradass, A.H. Jadhav, K.H. Kim, H. Kim, J. Alloys Compd. 517, 164–169 (2012)

P. Yaseneva, M. Bowker, G. Hutchings, Phys. Chem. Chem. Phys. 13, 18609–18614 (2011)

L. Li, Sol Gel Sci. Technol. 58, 677–681 (2011)

D. Varshney, K. Verma, A. Kumar, J.Mol. Struct. 1006, 447–452 (2011)

A. Lassoued, M.S. Lassoued, B. Dkhil, A. Gadri, S. Ammar, J. Mol. Struct. 1148, 276–281 (2017)

A. Lassoued, B. Dkhil, A. Gadri, S. Ammar, J. Results Phys. 7, 3007–3015 (2017)

A. Lassoued, M.S. Lassoued, B. Dkhil, A. Gadri, S. Ammar, J. Mol. Struct. 1141, 99–106 (2017)

M.T. Jamil, J. Ahmad, S.H. Bukhari, T. Sultan, M.Y. Akhter, H. Ahmad, G. Murtaza, J. Ovonic Res. 13, 45–53 (2017)

S. Chakrabarty, A. Dutta, M. Pal, J. Alloys Compd. 625, 216–223 (2015)

N. Singh, A. Agarwal, S. Sanghi, P. Singh, J. Magn. Magn. Mater. 323, 486–492 (2011)

A.C.F.M. Costa, E. Tortella, M.R. Morelli, R.H.G.A. Kiminami, J. Magn. Magn. Mater. 256, 174–182 (2003)

K.H. Wu, T.H. Ting, G.P. Wang, C.C. Yang, B.R. Mc, Garvey, Mater. Res. Bull. 40, 2080–2088 (2005)

B.P. Rao, A. Mahesh Kumar, K.H. Rao, Y.L.N. Murthy, O.F. Caltun, I. Dumitru, L. Spinu, J. Optoelctron. Adv. Mater. 8, 1703–1705 (2006)

A.A.K.M. Hossain, S.T. Mahmud, M. Seki, T. Kawai, H. Tabata, J. Magn. Magn. Mater. 312, 210–219 (2007)

W. Yan, W. Jiang, Q. Zhang, Y. Li, H. Wang, Mater. Sci. Eng. B 171, 144–148 (2010)

L.R. Penn, J. Phys. Chem. B. 108, 12707–12712 (2004)

B. Jia, L. Gao, Crystal Growth Design 8, 1372–1376 (2008)

S. Atiq, M. Majeed, A. Ahmad, S. Kumail Abbas, M. Saleem, S. Riaz, S. Naseem, J. Ceram. Int. 43, 2486–2494 (2017)

W. Smith, Y.P. Zhao, Catal. Commun. 10, 1117–1121 (2009)

M. Mrowetz, W. Balcerski, A.J. Colussi, M.R. Hoffmann, J. Phys. Chem. B 108, 17269–17273 (2004)

Acknowledgements

The present work was supported by the Research Funds of Electrochemistry, Materials and Environment Research Unit UREME (UR17ES45), Faculty of Sciences Gabes University, Tunisia and Structures, Properties and Modeling of Solids (SPMS) Laboratory, University Paris-Saclay, France.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lassoued, A., Lassoued, M.S., Dkhil, B. et al. Nanocrystalline NixCo(0.5−x)Zn0.5Fe2O4 ferrites: fabrication through co-precipitation route with enhanced structural, magnetic and photo-catalytic activity. J Mater Sci: Mater Electron 29, 7333–7344 (2018). https://doi.org/10.1007/s10854-018-8723-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-018-8723-y