Abstract

The rapid depletion of energy resources is the most serious challenge facing humanity today. Energy consumption by buildings is the largest component of energy consumption, and most of it is in the form of heat loss. Therefore, many buildings use rigid polyurethane foam (PUF) as thermal insulation material to effectively reduce heat loss. However, the greatest disadvantage of PUF is its high flammability. In this work, to reduce the risk of fire caused by PUF, melamine-based polyol containing phosphonate and alkynyl groups (MF3.5 and MB3F3) is synthesized and used to improve the flame retardancy of PUF by replacing common polyether polyol. The effects of MF3.5 and MB3F3 on the physical and mechanical properties, cell morphology, thermal stability and flame retardancy of PUF are systematically studied. The research results show that the flame-retardant polyols have no effect on the thermal insulation properties of PUF, but result in a slight decrease in compressive strength. Thermogravimetric analysis proves that MF3.5 and MB3F3 can increase the temperature of the maximum mass loss rate and reduce the maximum mass loss rate, and significantly increase the char yield at 800 °C. The limiting oxygen index (LOI) value is increased to 24.3%. Cone calorimetry experiments show that MB3F3 reduces the peak heat release rate and total heat release by 28.2% and 30.5%, respectively. Vertical combustion tests show that the average burning rate of the flame-retardant PUF is much slower, and melt-dripping behavior is eliminated. The flame retardancy of PUF is improved mainly through a condensed phase mechanism.

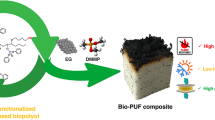

Graphic abstract

Similar content being viewed by others

References

Perez-Lombard L, Ortiz J, Pout C (2008) A review on buildings energy consumption information. Energy Build 40:394–398

Allouhi A, El Fouih Y, Kousksou T, Jamil A, Zeraouli Y, Mourad Y (2015) Energy consumption and efficiency in buildings: current status and future trends. J Clean Prod 109:118–130

Huberman N, Pearlmutter D (2008) A life-cycle energy analysis of building materials in the Negev desert. Energy Build 40:837–848

Cai WG, Wu Y, Zhong Y, Ren H (2009) China building energy consumption: situation, challenges and corresponding measures. Energy Policy 37:2054–2059

Al-Homoud MS (2005) Performance characteristics and practical applications of common building thermal insulation materials. Build Environ 40:353–366

Zhang C, Bhoyate S, Ionescu M, Kahol PK, Gupta RK (2018) Highly flame retardant and bio-based rigid polyurethane foams derived from orange peel oil. Polym Eng Sci 58:2078–2087

Xu ZB, Tang XL, Zheng JY (2008) Thermal stability and flame retardancy of rigid polyurethane foams/organoclay nanocomposites. Polym-Plast Technol Eng 47:1136–1141

Ding HY, Wang JF, Liu J, Xu YZ, Chen RQ, Wang CP, Chu FX (2015) Preparation and properties of a novel flame retardant polyurethane quasi-prepolymer for toughening phenolic foam. J Appl Polym Sci 132:42424

Visakh PM, Semkin AO, Rezaev IA, Fateev AV (2019) Review on soft polyurethane flame retardant. Constr Build Mater 227:116673

Bhoyate S, Ionescu M, Kahol PK, Chen J, Mishra SR, Gupta RK (2018) Highly flame-retardant polyurethane foam based on reactive phosphorus polyol and limonene-based polyol. J Appl Polym Sci 135:46224

Kirpluks M, Cabulis U, Zeltins V, Stiebra L, Avots A (2014) Rigid Polyurethane foam thermal insulation protected with mineral intumescent mat. Autex Res J 14:259–269

Thirumal M, Khastgir D, Nando GB, Naik YP, Singha NK (2010) Halogen-free flame retardant PUF: effect of melamine compounds on mechanical, thermal and flame retardant properties. Polym Degrad Stabil 95:1138–1145

Zhu H, Xu SA (2019) Synthesis and properties of rigid polyurethane foams synthesized from modified urea-formaldehyde resin. Constr Build Mater 202:718–726

Wang SP, Chen HX, Zhang LH (2014) Thermal decomposition kinetics of rigid polyurethane foam and ignition risk by a hot particle. J Appl Polym Sci 131:39359

Fournier D, De Geest BG, Du Prez FE (2009) On-demand click functionalization of polyurethane films and foams. Polymer 50:5362–5367

Chiu SH, Wang WK (1998) Dynamic flame retardancy of polypropylene filled with ammonium polyphosphate, pentaerythritol and melamine additives. Polymer 39:1951–1955

Chen MJ, Shao ZB, Wang XL, Chen L, Wang YZ (2012) Halogen-free flame-retardant flexible polyurethane foam with a novel nitrogen-phosphorus flame retardant. Ind Eng Chem Res 51:9769–9776

Horacek H, Grabner R (1996) Advantages of flame retardants based on nitrogen compounds. Polym Degrad Stabil 54:205–215

Saihi D, Vroman I, Giraud S, Bourbigot S (2005) Microencapsulation of ammonium phosphate with a polyurethane shell part 1: coacervation technique. React Funct Polym 64:127–138

Saihi D, Vroman I, Giraud S, Bourbigot S (2006) Microencapsulation of ammonium phosphate with a polyurethane shell. Part II. Interfacial polymerization technique. React Funct Polym 66:1118–1125

Lorenzetti A, Modesti M, Besco S, Hrelja D, Donadi S (2011) Influence of phosphorus valency on thermal behaviour of flame retarded polyurethane foams. Polym Degrad Stabil 96:1455–1461

Lubczak J, Chmiel-Bzukiewicz E, Duliban J, Glowacz-Czerwonka D, Lubczak R, Lukasiewicz B, Zarzyka I, Lodyga A, Tynski P, Koziol M, Majerczyk Z, Minda-Data D (2014) Polyurethane foams with 1,3,5-triazine ring of improved thermal stability. Przem Chem 93:1690–1697

Chmiel E, Lubczak J, Stagraczynski R (2017) Modification of polyurethane foams with 1,3,5-triazine ring and boron. Macromol Res 25:317–324

Lubczak J, Lukasiewicz B (2012) Oligoetherols and polyurethane foams with 1,3,5-triazine ring and boron atoms. Polymer 57:819–829

Wang C, Wu YC, Li YC, Shao Q, Yan XR, Han C, Wang Z, Liu Z, Guo ZH (2018) Flame-retardant rigid polyurethane foam with a phosphorus-nitrogen single intumescent flame retardant. Polym Adv Technol 29:668–676

Wu NJ, Li XT (2014) Flame retardancy and synergistic flame retardant mechanisms of acrylonitrile-butadiene-styrene composites based on aluminum hypophosphite. Polym Degrad Stabil 105:265–276

Brehme S, Schartel B, Goebbels J, Fischer O, Pospiech D, Bykov Y, Döring M (2011) Phosphorus polyester versus aluminium phosphinate in poly(butyleneterephthalate) (PBT): flame retardancy performance and mechanisms. Polym Degrad Stabil 96:875–884

Li JW, Zeng XD, Kong DZ, Xu H, Zhang LP, Zhong Y, Sui XF, Mao ZP (2018) Synergistic effects of a novel silicon-containing triazine charring agent on the flame-retardant properties of poly(ethylene terephthalate)/hexakis (4-phenoxy)cyclotriphosphazene composites. Polym Compos 39:858–868

Li B, Xu MJ (2006) Effect of a novel charring-foaming agent on flame retardancy and thermal degradation of intumescent flame retardant polypropylene. Polym Degrad Stabil 91:1380–1386

Shi L, Li ZM, Xie BH, Wang JH, Tian CR, Yang MB (2006) Flame retardancy of different-sized expandable graphite particles for high-density rigid polyurethane foams. Polym Int 55:862–871

Hu XM, Wang DM (2013) Enhanced fire behavior of rigid polyurethane foam by intumescent flame retardants. J Appl Polym Sci 129:238–246

Chen CK, Zhao XL, Shi CL, Chen J (2018) Synergistic effect between carbon nanoparticle and intumescent flame retardant on flammability and smoke suppression of copolymer thermoplastic polyurethane. J Mater Sci 53:6053–6064. https://doi.org/10.1007/s10853-017-1970-0

Funding

This research did not receive any specific grants from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Gregory Rutledge.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jia, D., Yang, J., He, J. et al. Melamine-based polyol containing phosphonate and alkynyl groups and its application in rigid polyurethane foam. J Mater Sci 56, 870–885 (2021). https://doi.org/10.1007/s10853-020-05266-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05266-2