Abstract

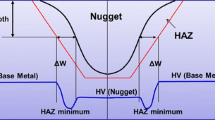

Dissimilar friction stir welds of aluminum alloys AA5086 in annealed and AA6061 in T6 temper conditions were investigated in terms of residual stress, grain structure and precipitation distribution in different zones of the welded joints. Optical metallography and transmission electron microscopy were used to characterize microstructures of different zones of the welds. In addition, residual stress profile and local mechanical properties of different zones were evaluated employing X-ray diffraction method and digital image correlation technique. It was found that softening in the AA6061-T6 side occurs in regions with weld peak temperature higher than 300 °C. The micro-hardness profile results and TEM investigations also showed that thermo-mechanical affected zone of AA6061 side with large plate-shaped β precipitates is the softest region of the joints in AA6061 side. Furthermore, residual stress distribution within the samples is not directly dependent on the local mechanical properties of different zones of the joints.

Similar content being viewed by others

References

Peel MJ, Steuwer A, Withers PJ, Dlckerson T, Shi Q, Sherclif H (2006) Metall Mater Trans A 37:2183

Peel MJ, Steuwer A, Withers PJ (2006) Metall Mater Trans A 37:2195

Ghosh M, Kumar K, Kailas SV, Ray AK (2010) Mater Des 31:3033

Leitao C, Emílio B, Chaparro BM, Rodrigues DM (2009) Mater Des 30:3235

Leitao C, Leal RM, Rodrigues DM, Loureiro A, Vilaca P (2009) Mater Des 30:101

Cavaliere P, Squillace A (2006) Mater Sci Forum 519–521:1163

Cavaliere P, Cerri E, Squillace AA (2005) J Mater Sci 40:3669. doi:10.1007/s10853-005-0474-5

Steuwer A, Peel MJ, Withers PJ (2006) Mater Sci Eng A 441:187

da Silva AAM, Arruti E, Janeiro G, Aldanondo E, Alvarez P, Echeverria A (2011) Mater Des 32:2021

Amancio-Filho ST, Sheikhi S, dos Santos JF, Bolfarini C (2008) J Mater Process Technol 206:132

Jamshidi Aval H, Serajzadeh S, Kokabi AH (2011) J Mater Sci 46:3258. doi:10.1007/s10853-010-5213-x

ASTM E8-4 (2004) Standard test methods for tension testing of metallic materials. American Society for Testing and Materials, Philadelphia, PA

Liu HJ, Shen JJ, Huang YX, Kuang LY, Liu C, Li C (2009) Sci Technol Weld Join 14(6):577

Mishra RS, Mahoney MW (2007) Friction stir welding and processing. ASM International, Materials Park, p 51

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena, 2nd edn. Elsevier, Oxford

Jamshidi Aval H, Serajzadeh S, Kokabi AH, Loureiro A (2011) Sci Technol Weld Join 16:597

Edwards GA, Stiller K, Dunlop GL, Couper MJ (1998) Acta Mater 46:3893

Olea CAW, Roldo L, dos Santos JF, Strohaecker TR (2007) Mater Sci Eng A 454–455:52

Sato YS, Kokawa H, Enomoto M, Jogan S (1999) Metall Mater Trans A 30:1999

Chakrabarti DJ, Laughlin DE (2004) Prog Mater Sci 49:389

Wang X, Esmaeili S, Lloyd DJ (2006) Metall Mater Trans A 37:2691

Weis Olea CA (2008) Influence of energy input in friction stir welding on structure evolution and mechanical behaviour of precipitation-hardening in aluminium alloys (AA2024-T351, AA6013-T6 and Al–Mg–Sc). GKSS-Forschungszentrum, Bibliothek

Woo W, Feng Z, Wang X-L, Hubbard CR (2009) Scr Mater 61:624

Acknowledgements

The authors would like to acknowledge the great help of Prof. A. C. Batista, Residual Stresses and Engineering Materials group’s member of CEMDRX Research Center of Coimbra University, for measuring residual stress. Also, the authors are indebted to the Portuguese Foundation for the Science and Technology (FCT) through COMPETE program from QREN and to FEDER for the financial support. The first author also wishes to thank the Iranian Ministry of Science, Research and Technology for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jamshidi Aval, H., Serajzadeh, S., Sakharova, N.A. et al. A study on microstructures and residual stress distributions in dissimilar friction-stir welding of AA5086–AA6061. J Mater Sci 47, 5428–5437 (2012). https://doi.org/10.1007/s10853-012-6430-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6430-2