Abstract

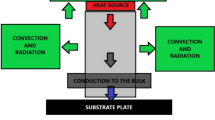

Pulse Electrochemical Machining (PECM) is a manufacturing process which provides an economical and effective method for machining hard materials into complex shapes. One important drawback of ECM is the lack of quantitative simulation software to predict the tool shape and machining parameters necessary to produce a given work-piece profile. Calculating temperature distributions in the system allows more accurate simulations, as well as the determination of the thermal limits of the system. In this paper temperature transients over multiple pulses are calculated. It is found that the way the system is modeled has a great impact on the temperature evolution in the thermal boundary layer. The presence of massive electrodes introduces extra time scales which may not be negligible. It is advantageous to identify the thermal time scales in the system, to see whether the heat produced during separate pulses will accumulate or not during the process. The occurring thermal time scales in the system are discussed in detail.

Similar content being viewed by others

Abbreviations

- a :

-

Polarization parameter 1/S m−2

- A :

-

Electrode surface/m2

- b :

-

Polarization parameter 2/A m−2

- Bi :

-

Biot number/−

- C p :

-

Heat capacity/J kg−1 K−1

- D 0,i :

-

Diffusion coefficients at infinite dilution/m2 s−1

- E 0 :

-

Equilibrium potential/V

- Fo :

-

Fourier number/−

- h :

-

Heat transfer coefficient/W m−2 K−1

- H :

-

Characteristic size electrode/m

- I :

-

Electrical current/A

- J :

-

Current density distribution/A m−2

- k :

-

Thermal conductivity/W m−1 K−1

- k mol :

-

Molecular thermal conductivity/W m−1 K−1

- k turb :

-

Turbulent thermal conductivity/W m−1 K−1

- L :

-

Electrode length/m

- P doublelayer :

-

Heat produced in the double layer/W m−2

- P bulk :

-

Heat produced in the bulk/W m−3

- Pr t :

-

Turbulent Prandtl number/−

- q :

-

Heat/W

- St 0 :

-

Strouhal number/−

- St 0 :

-

Strouhal number for flushing period/−

- t :

-

Time/s

- t 0 :

-

Pulse off-time/s

- T :

-

Pulse period/s

- Δt c :

-

Transient duration due to convection/s

- U :

-

Potential distribution/V

- ν:

-

Scalar velocity/m s−1

- \({\bar{\nu}}\) :

-

Velocity vector/m s−1

- V :

-

Volume/m2

- x :

-

Distance/m

- α :

-

Duty cycle/−

- α′ :

-

Thermal diffusivity/m2 s−1

- η :

-

Overpotential/V

- θ :

-

Relative temperature/K

- θ′ :

-

Normalized temperature/K

- Θ:

-

Temperature/K

- Θi :

-

Initial temperature/K

- Θ∞ :

-

Reference temperature/K

- \({\hat{\lambda}_n}\) :

-

Transcendental coefficients/−

- μ :

-

Dynamic viscosity/kg m−1 s−1

- ρ :

-

Density/kg m−3

- σ :

-

Electrical conductivity/S m−1

- τ :

-

Time constant/s

References

D. Risco, A. Davydov (1993). J. Am. Soc. Mech. Eng. 64:701

J. McGeough (1974). Principles of Electrochemical Machining. J. Wiley & Sons, New York

K.P. Rajurkar, D. Zhu, J.A. McGeough, J. Kozak, A. De Silva (1999). Ann. CIRP 48(2):567

M. Lohrengel, I. Kluppel, C. Rosenkranz, H. Betterman, J. Schultze (2003). Electrochim. Acta. 48(20–22):3203

A. Mount, D. Clifton, P. Howarth, A. Sherlock (2003). J. Mater. Process.Technol. 138:449

M. Datta, D. Landolt (1981). Electrochim. Acta 7:899

J. Kozak (2004). Bull. Polish Acad. Sci. Tech. Sci. 52:313

J. Kozak, K. Rajurkar (1991). J. Mater. Process. Technol. 28(1–2): 149

W. Clark, J. McGeough (1977). J. Appl. Electrochem. 7:277

J. Kozak, K. Rajurkar, K. Lubkowski (1997). Trans. NAMRI/SME. XXV:159

S. Loutrel, N. Cook (1973). ASME J. Eng. Indust. 95(B/4):1003

S. Van Damme, G. Nelissen, B. Van Den Bossche, J. Deconinck (2006). J. Appl. Electrochem. 36(1):1

G. Nelissen, B. Van Den Bossche, J. Deconinck, A. Van Theemsche, C. Dan (2003). J. Appl. Electrochem. 33(10):863

G. Nelissen, A. Van Theemsche, C. Dan, B. Van Den Bossche, J. Deconinck (2004). J. Electroanal. Chem. 563(2):213

N. Waterson (2003) Simulation of Turbulent Flow Heat and Mass Transfer Using a Residual-distribution Approach, Dissertation (Technical University, Delft)

C. Dan, B. Van Den Bossche, L. Bortels, G. Nelissen, J. Deconinck (2001). J. Electroanal. Chem. 505:12

M. Purcar (2005) Development and Evaluation of Numerical Models and Methods for Electrochemical Machining and Electroforming Applications, Dissertation. Vrije Universiteit Brussel, Brussels

H.S.J. Altena, Precision ECM by Process Characteristic Modelling, Dissertation (Glasgow Caledonian University, 2000).

G. Nelissen (2003) Simulation of Multi-ion Transport in Turbulent Flow Dissertation. Vrije Universiteit Brussel, Brussels

W.A. Strauss (1992) Partial Differential Equations: An Introduction . J. Wiley & Sons, New York

J.H. Lienhard IV and J.H. Lienhard V, A heat transfer textbook, 3rd edn. (Phlogiston Press, Cambridge, Massachusetts, 2005), 762 pp.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Smets, N., Van Damme, S., De Wilde, D. et al. Calculation of temperature transients in pulse electrochemical machining (PECM). J Appl Electrochem 37, 315–324 (2007). https://doi.org/10.1007/s10800-006-9259-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-006-9259-z