Abstract

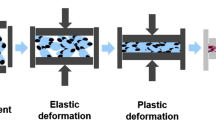

We investigate, via granular dynamics simulations, the influence of particle size dispersity on the packing characteristics of uniaxially compacted pharmaceutical blends. We employ reduced models of representative pharmaceutical excipient blends comprised of one, two, four and six components of different size, where the grain size in each component is distinct. We investigate the particle dynamics and reorganization during the compaction phase after the blend has been poured into a tablet die. For small strains, we demonstrate the packing fraction of the powder blends to scale linearly with the axial strain. We do not observe any significant variation in the stress response of the blend with particle size dispersity at small strains, but the mixtures with greater particle size dispersity remain compactible up to higher strains than the less polydisperse mixtures.

Similar content being viewed by others

References

Jaeger, H.M., Nagel, S.R., Behringer, R.P.: Granular solids, liquids, and gases. Rev. Mod. Phys. 68, 1259–1273 (1996)

Benedict, M., Dutt, M., Elliott, J.A.: Dynamically tessellating algorithm for analysis of pore size distribution in particle agglomerates. Phys. A 378, 465–474 (2007)

Johnson, K.L.: Contact Mechanics. Cambridge University Press, United Kingdom (1987)

Silbert, L.E., Ertaç, D., Grest, T.C., Halsey, T.C., Levine, D.: Geometry of frictionless and frictional sphere packings. Phys. Rev. E 65, 031304 (2002)

Silbert, L.E., Ertaç, D., Grest, G.S., Halsey, T.C., Levine, D., Plimpton, S.J.: Granular flow down an inclined plane: bagnold scaling and rheology. Phys. Rev. E 64, 051302 (2001)

de Gennes, P.G.: Granular matter: a tentative view. Rev. Mod. Phys. 71, S374–S382 (1999)

Geng, J., Longhi, E., Behringer, R.P., Howell, D.W.: Memory in two-dimensional heap experiments. Phys. Rev. E 64, 060301 (2001)

Wu, C.-Y., Ruddy, O.M., Bentham, A.C., Hancock, B.C., Best, S.M., Elliott, J.A.: Modelling the mechanical behaviour of pharmaceutical powders during compaction. Powder Technol. 152, 107–117 (2005)

Dutt, M., Hancock, B., Bentham, C., Elliott, J.: An implementation of granular dynamics for simulating frictional elastic particles based on the DL\_POLY code. Comp. Phys. Comm. 166, 26–44 (2005)

Rosato, A., Strandburg, K.J., Prinz, F., Swendsen, R.H.: Why the Brazil nuts are on top: size segregation of particulate matter by shaking. Phys. Rev. Lett. 58, 1038–1040 (1987)

Fu, X., Dutt, M., Bentham, A.C., Hancock, B.C., Cameron, R.E., Elliott, J.A.: Investigation of particle packing in model pharmaceutical powders using X-ray microtomography and discrete element method. Powder Technol. 167, 134–140 (2006)

Alderborn, G., Nystöm, C. (eds.): Pharmaceutical Powder Compaction Technology. Marcel Dekker Inc., New York (1996)

Roberts, R.J., Rowe, R.C., York, P.: The Poisson’s ratio of microcrystalline cellulose. Int. J. Pharm. 105, 177–180 (1994)

Coulomb, C.: Mémoire de Mathematique et de Physique 7, 343 (1773)

Åström, J.A., Herrmann, H.J., Timonen, J.: Granular packings and fault zones. Phys. Rev. Lett. 84, 638–641 (2000)

Dutt, M., Hancock, B., Bentham, C., Elliott, J.: Granular templating: effects of boundary structure on particle packings under simultaneous shear and compression. Europhys. Lett. 77, 18001 (2007)

Landry, J.W., Grest, G.S., Silbert, L.E., Plimpton, S.J.: Confined granular packings: structure, stress, and forces. Phys. Rev. E 67, 041303 (2003)

Makse, H.A., Johnson, D.L., Schwartz, L.M.: Packing of compressible granular materials. Phys. Rev. Lett. 84, 4160–4163 (2000)

Thornton, C.: Numerical simulations of deviatoric shear deformation of granular media. Geotechnique 50, 43–53 (2000)

Michrafy, A., Ringenbacher, D., Tcholeroff, P.: Modelling compaction behaviour of powders: application to pharmaceutical powders. Powder Technol. 127, 257–266 (2002)

Sheng, Y., Lawrence, C.J., Briscoe, B.J., Thornton, C.: Numerical studies of uniaxial powder compaction process by 3D DEM. Eng. Comput. 21, 304–317 (2004)

Wu, C.-Y., Ruddy, O.M., Bentham, A.C., Hancock, B.C., Best, S.M., Elliott, J.A.: Modelling the mechanical behaviour of pharmaceutical powders during compaction. Powder Technol. 152, 107–117 (2005)

Morgeneyer, M., Brendel, L., Schwedes, J.: Compaction of bidispersive cohesive powders. Granul. Matter 10, 295–299 (2008)

Ogarko, V., Luding, S.: Prediction of polydisperse hard-sphere mixture behavior using tridisperse systems, Soft Matter 9, 9530–9534 (2013)

Kumar, N., Imole, O.I., Magnanimo, V., Luding, S.: Effects of polydispersity on the micro-macro behavior of granular assemblies under different deformation paths. Particoulogy (2013) (online)

Imole, O.I., Magnanimo, V., Luding, S.: Micro-macro correlations and anisotropy in granular assemblies under uniaxial loading and unloading. Phys. Rev. E (2013) (submitted)

Imole, O.I., Kumar, N., Magnanimo, V., Luding, S.: Hydrostatic and shear behavior of frictionless granular assemblies under different deformation conditions. KONA 30, 84–108 (2013)

Masin, D.: Asymptoic behavior of granular materials, hydrostatic and shear behavior of frictionless granular assemblies under different deformation conditions (2013, in press)

Acknowledgments

We would like to acknowledge Pfizer Inc. for providing financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dutt, M., Elliott, J.A. Granular dynamics simulations of the effect of grain size dispersity on uniaxially compacted powder blends. Granular Matter 16, 243–248 (2014). https://doi.org/10.1007/s10035-013-0463-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-013-0463-3