Abstract

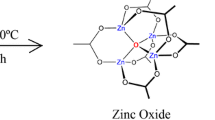

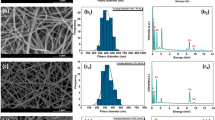

Zinc oxide (ZnO) nanofibers were prepared by electrospinning under different conditions using a solution of poly(vinyl alcohol) and zinc acetate as precursor. A 23 factorial design was made to study the influence of the process parameters in the electrospinning (collector distance, flow rate and voltage), and a 22 factorial design was made to study the influence of the calcination process (time and temperature). SEM images were made to analyze the fiber morphology before and after calcination process, and the images were made to measure the nanofiber diameter. X-ray diffraction was made to analyze the total precursor conversion to ZnO and the elimination of the polymeric carrier.

Similar content being viewed by others

References

Y. Xia, P. Yang, Y. Sun, Y. Wu, B. Mayers, B. Gates, Y. Yin, F. Kim, H. Yan, Adv. Mater. 14, 353 (2003). doi:10.1002/adma.200390087

X. Liu, C. Chen, Y. Zhao, B. Jia, J. Nanomater. 2013, 1–7 (2013). doi:10.1155/2013/736375

D. Malwal, P. Gopinath, Crit. Rev. Environ. Sci. Technol. (2015). doi:10.1080/10643389.2015.1109913

C.J. Buchko, L.C. Chen, Y. Shen, D.C. Martin, Polymer 40, 7397–7407 (1999)

Md.A. Ali, K. Mondal, C. Singh, B.D. Malhotra, A. Sharma, Nanoscale 7, 7234 (2015). doi:10.1039/C5NR00194C

J.R. Dees, J.E. Spruiell, J. Appl. Polym. Sci. 18, 1053–1078 (1974). doi:10.1002/app.1974.070180408

P.J. Barham, A.J. Keller, Mater. Sci. 20, 2281–2302 (1985)

P.W. Gibson, H.L. Shreuder-Gibson, D. Rivin, AIChE J. 45, 190–194 (1999)

Z.-M. Huang, Y.-Z. Zhang, M. Kotaki, S. Ramakrishna, Compos. Sci. Technol. 63, 2223 (2003). doi:10.1016/S0266-3538(03)00178-7

N. Bhardwaj, S.C. Kundu, Biotechnol. Adv. 28, 325–347 (2010). doi:10.1016/j.biotechadv.2010.01.004

X. Zong, K. Kim, D. Fang, S. Ran, B.S. Hsiao, B. Chu, Polymer 43, 4403 (2002). doi:10.1016/S0032-3861(02)00275-6

L.S. Nair, S. Bhattacharyya, J.D. Bender, Y.E. Greish, P.W. Brown, H.R. Allcock, C.T. Laurencin, Biomacromolecules 5, 2212 (2004). doi:10.1021/bm049759j

C.S. Ki, D.H. Baek, K.D. Gang, K.H. Lee, I.C. Um, Y.H. Park, Polymer 46, 5094 (2005). doi:10.1016/j.polymer.2005.04.040

J.S. Lee, K.H. Choi, H.D. Ghim, S.S. Kim, D.H. Chun, H.Y. Kim, W.S. Lyoo, J. Appl. Polym. Sci. 93, 1638 (2004). doi:10.1002/app.20602

X.Y. Geng, O.H. Kwon, J.H. Jang, Biomaterials 26, 5427 (2005). doi:10.1016/j.biomaterials.2005.01.066

C.X. Zhang, X.Y. Yuan, L.L. Wu, Y. Han, J. Sheng, Mats. Eur. Polym. J. 41, 423 (2005). doi:10.1016/j.eurpolymj.2004.10.027

B. Ding, M. Wang, J. Yu, G. Sun, Sensors 9, 1609–1624 (2009). doi:10.3390/s90301609

Ü. Özgür, Y. Alivov, C. Liu, A. Teke, M.A. Reshchikov, S. Dogan, V. Avrutin, S.J. Cho, H. Morkoc, J. Appl. Phys. 98, 041301 (2005). doi:10.1063/1.1992666

C. Klingshirn, Chem. Phys. Chem. 8 782–803 (2007). doi:10.1002/cphc.200700002

S. Wei, M. Zhou, W. Du, Sens. Actuators, B 160, 753–759 (2011). doi:10.1016/j.snb.2011.08.059

J. Lee, D. Bhattacharyya, A.J. Easteal, J.B. Metson, Curr. Appl. Phys. 8, 42 (2008). doi:10.1016/j.cap.2007.04.010

H. Zhao, H.Y.R. Li, Polymer 47, 3207–3217 (2006). doi:10.1016/j.polymer.2006.02.089

X.M. Sui, C.L. Shao, Y.C. Liu, Appl. Phys. Lett. 87, 113115 (2005)

R. Pantani, G. Gorrasi, G. Vigliotta, M. Murariu, P. Dubois, Eur. Polym. J. 49, 3471–3482 (2013). doi:10.1016/j.eurpolymj.2013.08.005

K.T. Shalumon, K.H. Anulekha, S.V. Nair, S.V. Nair, K.P. Chennazhi, R. Jayakumar, Int. J. Biol. Macromol. 49, 247–254 (2011). doi:10.1016/j.ijbiomac.2011.04.005

S.-J. Shen, X. Hu, F. Wang, Q.-Y. Ma, M.-F. Gu, Mater. Sci. Eng., C 49, 612–622 (2015). doi:10.1016/j.msec.2015.01.025

X. Yang, C. Shao, H. Guan, X. Li, J. Gong, Inorg. Chem. Commun. 7, 176–178 (2004). doi:10.1016/j.inoche.2003.10.035

R. Siddeheswaran, R. Sankar, M.R. Babu, M. Rathnakumari, R. Jayavel, P. Murugakoothan, P. Sureshkumar, Cryst. Res. Technol. 41, 446–449 (2006). doi:10.1002/crat.200510603

Y. Chang, N. Zhang, M. Zhuang, X. Lu, Mater. Renew. Energy Environ. 1, 124–127 (2013). doi:10.1109/ICMREE.2013.6893629

W. Cui, X. Li, S. Zhou, J. Weng, J. Appl. Polym. Sci. 103, 3105–3112 (2007). doi:10.1002/app.25464

N. Dhanalakshmi, A.K. Lele, J.P. Jog, Mater. Today Commun. 3, 141–148 (2015). doi:10.1016/j.mtcomm.2015.01.002

R.C. Nonato, A.R. Morales, A.F.M. Vieira, S.V.G. Nista, L.H.I. Mei, B.C. Bonse, Appl. Phys. A 122, 1–11 (2016). doi:10.1007/s00339-016-9752-0

M.C. Morris, H.F. McMurdie, E.H. Evans, B. Paretzkin, H.S. Parker, N.C. Panagiotopoulos, Standard X-ray diffraction powder patterns, 1st edn. (National Bureau of Standards, JCPDS, 1981), p. 78

Y. Nishio, R.S. Manley, Macromolecules 21, 1270–1277 (1988). doi:10.1021/ma00183a016

S.A. Therona, E. Zussmana, A.L. Yarina, Polymer 45, 2017–2030 (2007). doi:10.1016/j.polymer.2004.01.024

S.V. Fridrikh, J.H. Yu, M.P. Brenner, G.C. Rutledge, Phys. Rev. Lett. 90, 144502 (2003). doi:10.1103/PhysRevLett.90.144502

D. Sun, C. Chang, S. Li, L. Lin, Nano Lett. 6, 839–842 (2006). doi:10.1021/nl0602701

J.B. Russell, Química Geral, vol. 1 (Pearson Education do Brasil, Makron Books, São Paulo, 1994)

K.H. Lee, H.Y. Kim, Y.M. La, D.R. Lee, N.H. Sung, J. Polym. Sci. Part B: Poly. Phys. 40, 2259–2268 (2002). doi:10.1002/polb.10293

C. Chang, K. Limkrailassiri, L. Lin, Appl. Phys. Lett. 93, 123111 (2008). doi:10.1063/1.2975834

S. Megelski, J.S. Stephens, D.B. Chase, J.F. Rabolt, Macromolecules 35, 8456 (2002). doi:10.1021/ma020444a

Acknowledgements

The authors are grateful to CAPES (Coordenação de Financiamento de Pessoal de Nível Superior) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nonato, R.C., Morales, A.R., Rocha, M.C. et al. Process parameters in the manufacture of ceramic ZnO nanofibers made by electrospinning. Appl. Phys. A 123, 92 (2017). https://doi.org/10.1007/s00339-016-0717-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0717-0