Abstract

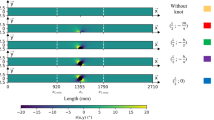

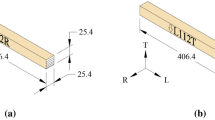

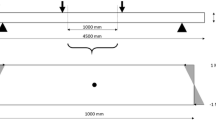

The influence of different types of knots and fiber deviations on the bending of wood, as managed using visual grading standards, was analytically discussed in this research by means of the finite element method. The effect of each geometrical variable on the strength and stress distribution has been studied individually. This was accomplished after validating a previously presented finite element model that accounted for the three-dimensional shape of the knots and fiber deviations. The simulated sizes and positions were those commonly managed by the standards for strength grading. The research presents the effect of: (1) the size and position of cylindrical face knots; (2) size and position of truncated conical face knots; (3) size and position of shallow conical face knots; (4) size and position of conical edge knots; (5) inclination of face knots. In each case, the analytical predictions of the modulus of rupture and stress distribution are detailed. Seven characteristic positions with distinct mechanical behavior were found, which should be accounted for in order to improve the wood grading efficiency.

Similar content being viewed by others

References

Argüelles B (1994) Prediction of the behavior of wooden pieces by animated simulation. Dissertation (in Spanish), Polytechnic University of Madrid, Madrid

Argüelles A, Arriaga F (1996) Estimation and design of wooden structures (in Spanish). AITIM, Madrid

Baño V (2009) Numerical analysis of wood strength loss due to the presence of knots. Dissertation (in Spanish), University of Santiago de Compostela, Lugo

Boström L (1992) Method for determination of the softening behavior of wood and the applicability of a non linear fracture mechanics model. Dissertation, Lund University, Lund

Cramer M, Goodman JR (1983) Model for stress analysis and strength prediction of lumber. Wood Fiber Sci 15(4):338–349

Foley C (2001) A three-dimensional paradigm of fiber orientation in timber. Wood Sci Technol 35:453–465

Grekin M (2006) Nordic Scots pine vs. selected competing species and non-wood substitute materials in mechanical wood products—literature survey. Working papers of the Finnish Forest Research Institute 36, Finnish Forest Research Institute, Finland

Guindos P, Guaita M (2013) A three-dimensional wood material model to simulate the behavior of wood with any type of knot at the macro-scale. Wood Sci Technol 47(3):585–599

Hashin Z (1980) Failure criteria for unidirectional fiber composites. J ApplMech 47:329–334

Hill R (1947) A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc Lond A 193:281–297

Hoffman O (1967) The brittle strength of orthotropic materials. J Compos Mater 1:200–206

Kasal B, Leichti RJ (2005) State of the art in multiaxial phenomenological failure criteria for wood members. Prog Struct Eng Mater 7(1):3–13

Landelius J (1989) Finite area method. Report TVSM 5043, Division of Structural Mechanics, Lund University, Lund

Liu JY (1984) Evaluation of the tensor polynomial strength theory for wood. J Compos Mater 18(3):216–226

Masuda M (1988) Theoretical consideration on fracture criteria of wood—proposal of a finite small area theory. In: Proceedings of the WCTE 1988, Seattle, vol 2, pp 584–595

Masuda M, Honda R (1994) Theoretical analysis on bending of lumber containing knots by using finite element method. MokuzaiGakkaishi 40:127–133

Mihashi H, Navi P, Sunderland H, Itagaki N, Ninomiya S (1999) Micromechanics of knot’s influence on tensile strength of Japanese cedar. In: Proceedings of first Rilem symposium on timber engineering, Stockholm, pp 181–190

Nahas MN (1986) Survey of failure and post-failure theories of laminated fiber-reinforced composites. J Compos Technol Res 8(4):138–153

Niskanen M, Silven O(2007) Machine vision based lumber grain measurement. In: MVA2007 IAPR conference on machine vision applications, Tokyo, pp 408–411

Norris CB (1962) Strength of orthotropic materials subjected to combined stresses. US Forest Products Laboratory, Report No. 1816, Madison

Pellicane PJ, Franco N (1994) Modeling wood pole failure. Part 2: material and geometric considerations. Wood Sci Technol 28:261–274

Phillips GE, Bodig J, Goodman JR (1981) Flow grain analogy. Wood Sci 14:55–64

INSTA 142 (2009) Nordic visual strength grading rules for timber

Saravi A, Lawrence PD, Lam F (2004) Implementation of a mechanics-based system for estimating the strength of timber. IEEE Trans Instrum Meas 53(2):284–292

Shen J, Shajer G, Parker R (1994) Theory and practice in measuring wood grain angle using microwaves. IEEE Trans Instrum Meas 43(6):803–809

Shih CF, Lee D (1978) Further developments in anisotropic plasticity. J Eng Mater 100:294–302

Thelandersson S, Larsen HJ (2003) Timber engineering. Wiley, UK

Tsai SW (1965) Strength characteristics of composite materials. NASA report no. CR-224, Washington DC

Tsai SW, Azzi VD (1966) Strength of laminated composite materials. AIAA J 4(2):296–301

Tsai SW, Wu EM (1971) A general theory of strength for anisotropic materials. J Compos Mater 5(1):58–80

UNE 56544 (2011) Visual grading for structural sawn timber. Coniferous timber

Valliappan S, Boonlaulohr P, Lee IK (1976) Non-linear analysis for anisotropic materials. Int J Numer Methods Eng 10:597–606

Yamada SE, Sun CT (1978) Analysis of laminate strength and its distribution. J Compos Mater 12:275–284

Zandenbergs JG, Smith FW (1988) Finite element fracture prediction for wood with knots and cross grain. Wood Fiber Sci 20(1):97–106

Acknowledgments

The authors are very grateful to both the Spanish Ministry of Education for its financial support through the National training program of University lecturers (FPU) and the Barrie de la Maza foundation for its postdoctoral research program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guindos, P., Guaita, M. The analytical influence of all types of knots on bending. Wood Sci Technol 48, 533–552 (2014). https://doi.org/10.1007/s00226-014-0621-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-014-0621-8