Abstract

Steam explosion is a process used to enhance enzyme penetration and digestibility of wood. Wood chips are processed with high-pressure steam for a limited time, and the bonding between polysaccharides and lignin is weakened. After this processing, the pressure is rapidly reduced to induce steam explosion where the vapor inside a fiber expands and exerts pressure on the fiber walls. This pressure causes fiber deformation and breakage. In this study, fiber deformation caused by vapor expansion was simulated by single wood fibers using finite element modeling. When pressure is applied inside a fiber, it is likely to break from the corner and midway between two adjacent corners. The fiber is modeled with four layers (P, S1, S2, and S3). Although the P, S1, and S3 layers are very thin, they significantly prevent fiber deformation. The fibers with a thin wall and a low micro-fibril angle (MFA) deform more than the fibers with a thick wall and a higher MFA. It was found that the shape of the fiber plays an important role in its deformation. The areas of localized strain are the most likely places for fiber splitting. Essentially, fiber wall damage is more likely to occur in (1) thin-walled fibers, i.e., earlywood, (2) fibers with damaged P and S1 layers, (3) fibers with low MFAs, and (4) fibers with irregular cross-sections. Different chemical pretreatments, fractionation procedures, and selections of raw materials can accordingly be considered to produce easily steam-exploded materials.

Similar content being viewed by others

References

Åkerholm M, Salmén L (2005) The oriented structure of lignin and its viscoelastic properties studied by static and dynamic FT-IR spectroscopy. Holzforschung 57:459–465

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861

Astley RJ, Stol KA, Harrington JJ (1998) Modeling the elastic properties of softwood part II: the cellular microstructure. Eur J Wood Prod 56(1):43–50

Avellar BK, Glasser WG (1998) Steam-assisted biomass fractionation. I. Process considerations and economic evaluation. Biomass Bioenerg 14(3):205–218

Bergander A, Salmén L (2000) Transverse elastic modulus of the native wood fibre wall. J Pulp Paper Sci 26(6):234–238

Bergander A, Salmén L (2002) Cell wall properties and their effects on the mechanical properties of fibers. J Mater Sci 37:151–156

Bjurhager I, Halonen H, Lindfors E-L, Iversen T, Almkvist G, Gamstedt EK, Berglund LA (2012) Degradation state in archaeological oak from the 17th century Vasa ship—substantial strength loss correlates with cellulose molar mass distribution. Biomacromolecules 13:2521–2527

Bodig J, Jayne BA (1982) Mechanics of wood and wood composites. Van Nostrand Reinhold, New York

Boutelje J (1968) Juvenile wood, with particular reference to northern spruce. Svensk Papperstidning 71:581–585

Brändström J (2001) Micro- and ultrastructural aspects of Norway spruce tracheids: a review. IAWA J 22(4):333–353

Cousins WJ (1976) Elastic modulus of lignin as related to moisture content. Wood Sci Technol 10:9–17

Cousins WJ (1978) Young’s modulus of hemicellulose as related to moisture content. Wood Sci Technol 12:161–167

de Magistris F, Salmén L (2008) Finite element modelling of wood cell deformation transverse to the fibre axis. Nordic Pulp Pap Res J 23(2):240–246

Donaldson LA, Wong KKY, Mackie KL (1988) Ultrastructure of steam-exploded wood. Wood Sci Technol 22:103–114

Eder M, Arnould O, Dunlop JWC, Hornatowska J, Salmén L (2013) Experimental micromechanical characterisation of wood cell walls. Wood Sci Technol 47:163–182

Gerhards CC (1982) Effect of moisture content and temperature on the mechanical properties of wood: an analysis of immediate effects. Wood Fiber 14(1):4–36

Gibson LJ, Ashby MF (1988) Cellular solids structure and properties. Pergamon press, New York, p 357

Halpin JC, Kardos JL (1976) The Halpin-Tsai equations: a review. Polym Eng Sci 16(5):344–352

Harrington JJ, Booker R, Astley RJ (1998) Modelling the elastic properties part I: the cell-wall lamellae. Eur J Wood Product 56(1):37–41

Jedvert K, Saltberg A, Lindström ME, Theliander H (2012) Mild steam explosion and chemical pre-treatment of Norway spruce. Bioresource 7(2):2051–2074

Josefsson T, Lennholm H, Gellerstedt G (2002) Changes in cellulose supramolecular structure and molecular weight distribution during steam explosion of aspen wood. Cellulose 8:1–8

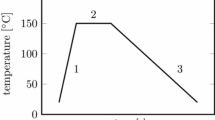

Kamke FA, Kutnar A (2010) Transverse compression behavior of wood in saturated steam at 150–170 °C. Wood Fiber Sci 42(3):377–387

Keunecke D, Sonderegger W, Pereteanu K, Luthi T, Niemz P (2007) Determination of Young’s and shear moduli of common yew and Norway spruce by means of ultrasonic waves. Wood Sci Technol 41:309–327

Koran Z (1979) Tensile properties of spruce under different conditions. Wood Fiber 11(1):38–49

Li X, Zhou Y, Yan Y, Cai Z, Feng F (2010) A single cell model for pretreatment of wood by microwave explosion. Holzforschung 64:633–637

Mark RE (1967) Cell wall mechanics of tracheids. Yale University Press, New Haven

Neagu RC, Gamstedt EK (2007) Modelling of effects of ultrastructural morphology on the hygroelastic properties of wood fibres. J Mater Sci 42:10254–10274

Neagu RC, Gamstedt EK, Bardage SL, Lindström M (2006) Ultrastructural features affecting mechanical properties of wood fibers. Wood Mater Sci Eng 1:146–170

Ohmiya K, Sakka K, Karita S, Kimura T (1997) Structure of cellulases and their applications. Biotechnol Genet Eng Rev 14:365–414

Persson K (2000) Micromechanical modelling of wood and fiber properties. Department of Mechanics and Materials, Lund University, Lund

Qing H, Mishnaevsky L Jr (2009) 3D hierarchical computational model of wood as a cellular material with fibril reinforced, heterogeneous multiple layers. Mech Mater 41:1034–1049

Sakurada I, Nubushina Y, Ito T (1962) Experimental determination of the elastic modulus of crystalline regions in oriented polymers. J Polym Sci 57:651–660

Salmén L, Fellers C (1982) The fundamentals of energy consumption during viscoelastic and plastic deformation of wood. Pulp Pap Can Trans Tech 4(9):93–99

Salmén L, Olsson A-M, Stevanic J, Simonović J, Radotić K (2012) Structural organisation of the wood polymers in the wood fibre structure. Bioresource 7(1):521–532

Shiari B, Wild PM (2004) Finite element analysis of individual wood-pulp fibers subjected to transverse compression. Wood Fiber Sci 36(2):135–142

Siimes FE (1967) The effect of specific gravity, moisture content, temperature and heating time on the tension and compression strength and elastic properties perpendicular to the grain of Finnish pine, spruce and birch wood and the significance of those factors on the checking of timber at kiln drying. Dissertation, The State Institute for Technical Research, Helsinki, Finland

Tanahashi M, Takada S, Aoki T, Goto T, Higuchi T, Hanai S (1982) Characterization of explosion wood: 1. Structure and physical properties. Wood Res 69:36–51

Trtik P, Dual J, Keunecke D, Mannes D, Niemz P, Stähli P, Kaestner A, Groso A, Stampanoni M (2007) 3D imaging of microstructure of spruce wood. J Struct Biol 159:45–55

Tsai SW (1992) Theory of composites design. Think Composites, Dayton

Tsai SW, Hahn HT (1980) Introduction to composite materials. In: Technomic pub, Lancaster

Tucker CL III, Liang E (1999) Stiffness predictions for unidirectional short-fiber composites: review and evaluation. Compos Sci Technol 59:655–671

Tyrväinen J (1995) Wood and fiber properties of Norway spruce and its suitability for thermomechanical pulping. Acta Forestalia Fennica 249:155

Uhmeier A, Salmén L (1996) Influence of strain rate and temperature on the radial compression behavior of wet spruce. J Eng Mater Technol 118:289–294

Young WC, Budynas RG (2002) Roark’s formulas for stress and strain, 7th edn. McGraw-Hill, New York

Yu Z, Zhang B, Yu F, Xu G, Song A (2012) A real explosion: the requirement of steam explosion pretreatment. Bioresour Technol 121:335–341

Zhang Y, Cai L (2006) Effect of steam explosion on wood appearance and structure of sub-alpine fir. Wood Sci Technol 40:427–436

Acknowledgments

Chalmers Energy Initiative is gratefully acknowledged for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muzamal, M., Gamstedt, E.K. & Rasmuson, A. Modeling wood fiber deformation caused by vapor expansion during steam explosion of wood. Wood Sci Technol 48, 353–372 (2014). https://doi.org/10.1007/s00226-013-0613-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00226-013-0613-0