Abstract

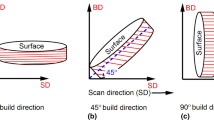

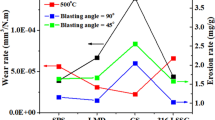

The aim of this study is to explore the wear performance of AISI 316L stainless steel fabricated via selective laser melting along different directions with respect to the building direction and via post annealing. The wear behavior of the alloy under high-speed sliding was investigated with high sliding velocities of up to 1 m/s. It was shown that the wear behavior of the alloy was completely different from that in quasi-static wear environments. The high-speed wear resistance was significantly affected by the building direction. After the annealing heat treatment of the alloy at 800 °C for 4 h, the high-speed wear resistance significantly decreased. Therefore, special care must be taken in using SLM 316L alloys when subjected to wear environments with high sliding velocities.

Similar content being viewed by others

References

Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges. Compos Part B Eng 143:172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Szost BA, Terzi S, Martina F, Boisselier D, Prytuliak A, Pirling T, Hofmann M, Jarvis DJ (2016) A comparative study of additive manufacturing techniques: residual stress and microstructural analysis of CLAD and WAAM printed Ti-6Al-4 V components. Mater Des 89:559–567. https://doi.org/10.1016/j.matdes.2015.09.115

Bandyopadhyay A, Heer B (2018) Additive manufacturing of multi-material structures. Mater Sci Eng R Rep 129:1–16. https://doi.org/10.1016/j.mser.2018.04.001

Singh R, Gupta A, Tripathi O, Srivastava S, Singh B, Awasthi A, Rajput SK, Sonia P, Singhal P, Saxena KK (2020) Powder bed fusion process in additive manufacturing: an overview. Mater Today Proc. https://doi.org/10.1016/j.matpr.2020.02.635

King WE, Anderson AT, Ferencz RM, Hodge NE, Kamath C, Khairallah SA, Rubenchik AM (2015) Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl Phys Rev 2:041304. https://doi.org/10.1063/1.4937809

Bhavar V, Kattire P, Patil V, et al (2017) A review on powder bed fusion technology of metal additive manufacturing. Addit Manuf Handb Prod Dev Def Ind 251–261. https://doi.org/10.1201/9781315119106

Li R, Shi Y, Wang Z, Wang L, Liu J, Jiang W (2010) Densification behavior of gas and water atomized 316L stainless steel powder during selective laser melting. Appl Surf Sci 256:4350–4356. https://doi.org/10.1016/j.apsusc.2010.02.030

Liverani E, Toschi S, Ceschini L, Fortunato A (2017) Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J Mater Process Technol 249:255–263. https://doi.org/10.1016/j.jmatprotec.2017.05.042

Bartolomeu F, Buciumeanu M, Pinto E, Alves N, Carvalho O, Silva FS, Miranda G (2017) 316L stainless steel mechanical and tribological behavior—a comparison between selective laser melting, hot pressing and conventional casting. Addit Manuf 16:81–89. https://doi.org/10.1016/j.addma.2017.05.007

AlMangour B, Grzesiak D, Yang JM (2017) Scanning strategies for texture and anisotropy tailoring during selective laser melting of TiC/316L stainless steel nanocomposites. J Alloys Compd 728:424–435. https://doi.org/10.1016/j.jallcom.2017.08.022

Dutta Majumdar J, Kumar A, Li L (2009) Direct laser cladding of SiC dispersed AISI 316L stainless steel. Tribol Int 42:750–753. https://doi.org/10.1016/j.triboint.2008.10.016

Kumar S, Kruth JP (2008) Wear performance of SLS/SLM materials. Adv Eng Mater 10:750–753. https://doi.org/10.1002/adem.200800075

Sun Y, Moroz A, Alrbaey K (2014) Sliding wear characteristics and corrosion behaviour of selective laser melted 316L stainless steel. J Mater Eng Perform 23:518–526. https://doi.org/10.1007/s11665-013-0784-8

Li H, Ramezani M, Li M, Ma C, Wang J (2018) Tribological performance of selective laser melted 316L stainless steel. Tribol Int 128:121–129. https://doi.org/10.1016/j.triboint.2018.07.021

Venkataraman B, Sundararajan G (1995) The high speed sliding wear behaviour of boronized medium carbon steel. Surf Coat Technol 73:177–184. https://doi.org/10.1016/0257-8972(94)02379-4

Ming Q, Yong-zhen Z, Jian-heng Y, Jun Z (2006) Microstructure and tribological characteristics of Ti-6Al-4V alloy against GCr15 under high speed and dry sliding. Mater Sci Eng A 434:71–75. https://doi.org/10.1016/j.msea.2006.07.043

Wilson S, Alpas AT (1998) TiN coating wear mechanisms in dry sliding contact against high speed steel. Surf Coat Technol 108–109:369–376. https://doi.org/10.1016/S0257-8972(98)00593-3

Kim T, Ha K, Cho YR, Jeon JB, Lee W (2019) Analysis of residual stress evolution during powder bed fusionprocess of AISI 316L stainless steel with experiment and numerical modeling. Int J Adv Manuf Technol 105:309–323. https://doi.org/10.1007/s00170-019-04204-0

Chowdhury SG, Singh R (2008) The influence of recrystallized structure and texture on the sensitization behaviour of a stable austenitic stainless steel (AISI 316L). Scr Mater 58:1102–1105. https://doi.org/10.1016/j.scriptamat.2008.02.005

Bhattacharjee PP, Sathiaraj GD, Zaid M, Gatti JR, Lee C, Tsai CW, Yeh JW (2014) Microstructure and texture evolution during annealing of equiatomic CoCrFeMnNi high-entropy alloy. J Alloys Compd 587:544–552. https://doi.org/10.1016/j.jallcom.2013.10.237

Prabhu TR, Arivarasu M, Chodancar Y, Arivazhagan N, Sumanth G, Mishra RK (2019) Tribological behaviour of graphite-reinforced FeNiCrCuMo high-entropy alloy self-lubricating composites for aircraft braking energy applications. Tribol Lett 67:1–15. https://doi.org/10.1007/s11249-019-1193-4

Liu Y, Zhai X, Deng Y, Wu D (2019) Tribological property of selective laser melting–processed 316L stainless steel against filled PEEK under water lubrication. Tribol Trans 62:962–970. https://doi.org/10.1080/10402004.2019.1635671

Farias MCM, Souza RM, Sinatora A, Tanaka DK (2007) The influence of applied load, sliding velocity and martensitic transformation on the unlubricated sliding wear of austenitic stainless steels. Wear 263:773–781. https://doi.org/10.1016/j.wear.2006.12.017

Qin W, Kang J, Li J, Yue W, Liu Y, She D, Mao Q, Li Y (2018) Tribological behavior of the 316L stainless steel with heterogeneous lamella structure. Materials (Basel) 11:1–12. https://doi.org/10.3390/ma11101839

Zhu Y, Chen X, Zou J, Yang H (2016) Sliding wear of selective laser melting processed Ti6Al4V under boundary lubrication conditions. Wear 368–369:485–495. https://doi.org/10.1016/j.wear.2016.09.020

Yang Y, Zhu Y, Khonsari MM, Yang H (2019) Wear anisotropy of selective laser melted 316L stainless steel. Wear 428–429:376–386. https://doi.org/10.1016/j.wear.2019.04.001

Rathod HJ, Nagaraju T, Prashanth KG, Ramamurty U (2019) Tribological properties of selective laser melted Al–12Si alloy. Tribol Int 137:94–101. https://doi.org/10.1016/j.triboint.2019.04.038

Godet M (1984) The third-body approach: a mechanical view of wear. Wear 100:437–452. https://doi.org/10.1016/0043-1648(84)90025-5

Berlet P, Dienwiebel M, Scherge M (2010) The effect of sample finishing on the tribology of metal/metal lubricated contacts. Wear 268:1518–1523. https://doi.org/10.1016/j.wear.2010.02.030

Lancaster JK (1990) Material-specific wear mechanisms: relevance to wear modelling. Wear 141:159–183. https://doi.org/10.1016/0043-1648(90)90200-T

Berthier Y (1990) Experimental evidence for friction and wear modelling. Wear 139:77–92. https://doi.org/10.1016/0043-1648(90)90210-2

Funding

This work was supported by a 2-year research grant of Pusan National University.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bae, K.C., Ha, K.S., Kim, Y.H. et al. Building direction dependence of wear resistance of selective laser melted AISI 316L stainless steel under high-speed tribological environment. Int J Adv Manuf Technol 108, 2385–2396 (2020). https://doi.org/10.1007/s00170-020-05572-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-05572-8