Abstract

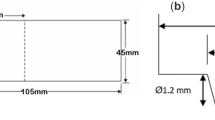

The plunge speed of the tool was divided into two plunge speeds, including pin- and shoulder-plunging speeds, for a detailed study of the plunging process in friction stir spot welding of A6061-T6 sheets. The effect of the pin- and shoulder-plunging speeds on hook geometries and mechanical properties was investigated. The results showed that the shoulder-plunging speed had an obvious effect on the hook geometry and tensile shear load, but the pin-plunging speed had almost no effect. The effective bond width (W eff) and effective sheet thickness (T eff) used to describe the hook geometry were important factors for determining the tensile shear load and fracture mode. Two fracture modes were observed: tensile/shear mixed fracture and shear fracture. The largest tensile shear load was obtained when the joint failed in the tensile/shear mixed fracture.

Similar content being viewed by others

References

Lakshminarayanan AK, Balasubramanian V, Elangovan K (2009) Effect of welding processes on tensile properties of AA6061 aluminium alloy joints. Int J Adv Manuf Technol 40(3–4):286–296

Karthikeyan R, Balasubramanian V (2010) Predictions of the optimized friction stir spot welding process parameters for joining AA2024 aluminum alloy using RSM. Int J Adv Manuf Technol 51(1–4):173–183

Gerlich AP, Shibayanagi T (2009) Grain boundary sliding during friction stir spot welding of an aluminum alloy. Scr Mater 60(4):236–239

Yin YH, Ikuta A, North TH (2010) Microstructural features and mechanical properties of AM60 and AZ31 friction stir spot welds. Mater Des 31(10):4764–4776

Hovanski Y, Santella ML, Grant GJ (2007) Friction stir spot welding of hot-stamped boron steel. Scr Mater 57(9):873–876

Bilici MK, Yukler AI (2012) Effects of welding parameters on friction stir spot welding of high density polyethylene sheets. Mater Des 33:545–550

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50(1–2):1–78

Badarinarayan H, Shi Y, Li X, Okamoto K (2009) Effect of tool geometry on hook formation and static strength of friction stir spot welded aluminum 5754-O sheets. Int J Mach Tools Manuf 49(11):814–823

Yuan W, Mishra RS, Webb S, Chen YL, Carlson B, Herling DR (2011) Effect of tool design and process parameters on properties of Al alloy 6016 friction stir spot welds. J Mater Process Technol 211(6):972–977

Yin YH, Sun N, North TH, Hu SS (2010) Influence of tool design on mechanical properties of AZ31 friction stir spot welds. Sci Technol Weld Join 15(1):81–86

Tozaki Y, Uematsu Y, Tokaji K (2007) Effect of tool geometry on microstructure and static strength in friction stir spot welded aluminium alloys. Int J Mach Tools Manuf 47(15):2230–2236

Tozaki Y, Uematsu Y, Tokaji K (2010) A newly developed tool without probe for friction stir spot welding and its performance. J Mater Process Technol 210(6–7):844–851

Shen ZK, Yang XQ, Zhang ZH, Cui L, Yin YH (2013) Mechanical properties and failure mechanisms of friction stir spot welds of AA 6061-T4 sheets. Mater Des 49:181–191

Bozzi S, Helbert-Etter AL, Baudin T, Klosek V, Kerbiguet JG, Criqui B (2010) Influence of FSSW parameters on fracture mechanisms of 5182 aluminium welds. J Mater Process Technol 210(11):1429–1435

Lin YC, Liu JJ, Lin BY, Lin CM, Tsai HL (2012) Effects of process parameters on strength of Mg alloy AZ61 friction stir spot welds. Mater Des 35:350–357

Lathabai S, Painter MJ, Cantin GMD, Tyagi VK (2006) Friction spot joining of an extruded Al–Mg–Si alloy. Scr Mater 55(10):899–902

Yoon SO, Kang MO, Kwon YJ, Hong ST, Park DH, Lee KH (2012) Influences of tool plunge speed and tool plunge depth on friction spot joining of AA5454-O aluminum alloy plates with different thicknesses. Trans Nonferrous Metals Soc 22(supplement 3):629–633

Jonckheere C, Meester BD, Cassiers C, Delhate M, Simar A (2012) Fracture and mechanical properties of friction stir spot welds in 6063-T6 aluminum alloy. Int J Adv Manuf Technol 62(5–8):569–575

Merzoug M, Mazari M, Berrahal L, Imad A (2010) Parametric studies of the process of friction spot stir welding of aluminium 6060-T5 alloys. Mater Des 31(6):3023–3028

Pathak N, Bandyopadhyay K, Sarangi M, Panda SK (2013) Microstructure and mechanical performance of friction stir spot-welded aluminum-5754 sheet. J Mater Eng Perform 22(1):131–144

Ministry of Machine Building and Electronics Industry (MMBEI) [PRC]. GB/T 2651-1989: method of tensile test for welded joint. National Standard of the People’s Republic of China. Released on 1989 May 8. China Association for Standardization, Beijing; c2000-05. http://www.chinacas.org/chinese/index.php

Badarinarayan H, Yang Q, Zhu S (2009) Effect of tool geometry on static strength of friction stir spot-welded aluminum alloy. Int J Mach Tools Manuf 49(2):142–148

Yin YH, Sun N, North TH, Hu SS (2010) Hook formation and mechanical properties in AZ31 friction stir spot welds. J Mater Process Technol 210(14):2062–2070

Zhang ZH, Yang XQ, Zhang JL, Zhou G, Xu XD, Zou BL (2011) Effect of welding parameters on microstructure and mechanical properties of friction stir spot welded 5052 aluminum alloy. Mater Des 32(8–9):4461–4470

Yang Q, Mironov S, Sato YS, Okamoto K (2010) Material flow during friction stir spot welding. Mater Sci Eng A 527(16–17):4389–4398

Song X, Xing L, Bu WD, Liu FC, Huang CP, Ke LM (2013) Effect of rotary direction and speed on mechanical properties in friction stir spot welding of A6061 sheets. China Weld 22(3):18–24

Babu S, Sankar VS, Janaki Ram GD, Venkitakrishnan PV, Madhusudhan Reddy G, Prasad Rao K (2013) Microstructures and mechanical properties of friction stir spot welded aluminum alloy AA2014. J Mater Eng Perform 22(1):71–84

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Song, X., Ke, L., Xing, L. et al. Effect of plunge speeds on hook geometries and mechanical properties in friction stir spot welding of A6061-T6 sheets. Int J Adv Manuf Technol 71, 2003–2010 (2014). https://doi.org/10.1007/s00170-014-5632-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5632-y