Abstract

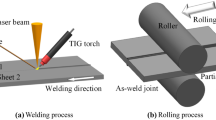

Four welding methods, including laser welding, gas tungsten arc (GTA) welding, laser–GTA hybrid welding, and laser–GTA hybrid welding with cold welding wire, are used to investigate the weldability of T-joints of magnesium alloy thin sheet. Stake welding process is presented in this paper in order to overcome the defects, such as stress concentration and deformation, and improve the accessibility of T-joints in fillet welding process. The effect of heat source type on weldability of T-joints is analyzed. The microstructures and mechanical properties are investigated. Experimental results indicate that comparing with the other three welding methods, laser–GTA hybrid welding with cold welding wire is the most effective process for T-joints of magnesium alloy thin sheet. In this process, T-joints are full penetration and the toes are smooth and round, and besides, reinforcement forms on the upside of weld bead by the filled wire. The mechanical properties of T-joints made with laser–GTA hybrid welding with cold welding wire achieve 90 % of that of base metal and are superior to that without welding wire.

Similar content being viewed by others

References

Mahendran G, Balasubramanian V, Senthilvelan T (2009) Developing diffusion bonding windows for joining AZ31B magnesium and copper alloys. Int J Adv Manuf Technol 42:689–695

Kulekci MK (2008) Magnesium and its alloys applications in automotive industry. Int J Adv Manuf Technol 39:851–865

Zhao LM, Zhang ZD (2008) Effect of Zn alloy interlayer on interface microstructure and strength of diffusion-bonded Mg-Al joints. Scr Mater 58:283–286

Zhang Z, Zhang F (2009) Spectral analysis of welding plasma of magnesium alloy using flux coated wire. Mater Trans 50:1909–1914

Nyberg EA, Luo AA, Sadayappan K, Shi W (2008) Magnesium for future autos. Advan Mater Process 166:35–37

Hao X, Song G (2009) Spectral analysis of the plasma in low-power laser/arc hybrid welding of magnesium alloy. IEEE Trans Plasma Sci 37:76–82

Kim J-D, Lee J-H, Kim J-S (2010) Characteristics of butt-welded joints on AZ31 magnesium alloy using a Nd:YAG laser. Int J Precis Eng Manuf 11:369–373

Ren D, Liu L, Li Y (2011) Investigation on overlap joining of AZ61 magnesium alloy: laser welding, adhesive bonding, and laser weld bonding. Int J Adv Manuf Technol. doi:10.1007/s00170-011-3683-x

Padmanaban G, Balasubramanian V (2010) An experimental investigation on friction stir welding of AZ31B magnesium alloy. Int J Adv Manuf Technol 49:111–121

Yoon JW, Bray GH, Valente RAF, Childs TER (2009) Buckling analysis for an integrally stiffened panel structure with a friction stir weld. Thin Wall Struct 47:1608–1622

Romanoff J, Remes H, Socha G, Jutila M, Varsta P (2007) The stiffness of laser stake welded T-joints in web-core sandwich structures. Thin Wall Struct 45:453–462

Kudzys A (2006) The structural safety of connections with fillet welds. J Constr Steel Res 62:1238–1243

Teng T-L, Fung C-P, Chang P-H, Yang W-C (2001) Analysis of residual stress and distortions in T-joints fillet welds. Int J Press Vessel Pip 78:523–538

Gao YF, Zhang H, Mao ZW (2009) Welding gun inclination detection and curved fillet weld joint tracking. Weld J 88:45–53

Mueller-Hummel P, Ferstl S, Sengotta M, Lang R (2002) Laser beam welding of high stressed, complex aircraft structural parts. First International Symposium on High-Power Laser Macroprocessing, Washington, March, 4831:438–441

Mattei S, Grevey D, Mathieu A, Kirchner L (2009) Using infrared thermography in order to compare laser and hybrid (laser+MIG) welding processes. Opt Laser Technol 41:665–670

Mahrle A (2006) Hybrid laser beam welding—classification, characteristics, and applications. J Laser Appl 18:169–180

Zhang YM, Zhang SB (1999) Welding aluminum alloy 6061 with the opposing dual-torch GTAW process. Weld J 78:202–206

Zhang YM, Pan C, Male AT (2000) Improved microstructure and properties of 6061 aluminum alloy weldments using a double-sided arc welding process. Metall Mater Trans A 31:2537–2543

Rodil SS, Gomez RA, Bernardez JM, Rodriguez F, Miguel LJ, Peran JR (2010) Laser welding defects detection in automotive industry based on radiation and spectroscopical measurements. Int J Adv Manuf Technol 49:133–145

Cao X, Jahazi M, Immarigeon JP, Wallace W (2006) A review of laser welding techniques for magnesium alloys. J Mater Process Technol 171:188–204

Hao X, Liu L (2009) Effect of laser pulse on arc plasma and magnesium target in low-power laser/arc hybrid welding. IEEE Trans Plasma Sci 37:2197–2201

Al-Kazzaz H, Medraj M, Cao X, Jahazi M (2008) Nd:YAG laser welding of aerospace grade ZE41A magnesium alloy: modeling and experimental investigations. Mater Chem Phys 109:61–76

Pastor M, Zhao H, Martukanitz RP, Debroy T (1999) Porosity, underfill and magnesium loss during continuous wave Nd:YAG laser welding of thin plates of aluminum alloys 5182 and 5754. Weld J 78:207–216

Liming L, Mingsheng C, Gang S, Jifeng W (2006) Numefjcal simulation of AZ31B magnesium alloy laser-GTAW hybrid welding with new heat source model. China J Mech Eng 42:82–85

Hort N, Huang Y, Kainer KU (2006) Intermetallics in magnesium alloys. Adv Eng Mater 8:235–240

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, C., Liu, L. Investigation on weldability of magnesium alloy thin sheet T-joints: arc welding, laser welding, and laser-arc hybrid welding. Int J Adv Manuf Technol 65, 27–34 (2013). https://doi.org/10.1007/s00170-012-4145-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4145-9