Abstract

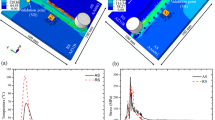

This paper presents finite element simulation results of instrumented FSW experiments on aluminium alloys 6005A-T6 and 2024-T3. The SAMCEF™ finite element code is used to perform the simulations. The FE model involves a sequential thermal-mechanical analysis and includes contact between the meshed tool, workpiece and backing plate. The model takes into account the pressure applied by the tool on the weld as well as the heat input. The heat transfers such as convection in air and contact conductance with the backing plate are modelled. For each experiment, the temperature time-histories were recorded at several locations in the workpiece. The heat input in the finite element model is identified by minimising the objective function of a constrained problem using a genetic optimisation algorithm. The objective function is the square of the difference between the experimental measurements and the numerical prediction of temperature. Finally, levels of residual stress predicted by simulation are presented.

Similar content being viewed by others

References

D’Alvise L., Massoni E., Walløe S.: Finite element modelling of the inertia friction welding process between dissimilar materials, Journal of Materials Processing Technology, 2002, 125-126, 387–391.

Pierret S.: MAX User Manual, CENAERO, Gosselies, Belgium, 2004.

Shi Q.-Y., Dickerson T., Shercliff H.R.: Thermo-mechanical FE modelling of friction stir welding of A2024 including tool loads, 2003, Proc. 4th Int. Symp. Friction Stir Welding, Park City, Utah, USA.

Chen C.M., Kovacevic R.: Finite element modelling of friction stir welding — thermal and thermomechanical analysis, Int. J. Machine Tools & Manufacture, 2003, vol. 43, pp. 1319–1326.

Colegrove P.A., Shercliff H.R., Threadgill P.L.: Modelling and development of the TrivexTM friction stir welding tool, 2003, Proc. 4th Int. Symp. Friction Stir Welding, Park City, Utah, USA.

Ulysse P.: Three-dimensional modelling of the friction stir welding process, Int. J. Machine Tools & Manufacture, 2002, vol. 42, pp. 1549–1557.

Carton M., Geelen S., Lecomte-Beckers J.: Thermal characterisation of the 2024-T3 aluminium alloy, March 2004, CENAERO Internal Report.

Pierret S., van den Braembussche R.: Turbomachinery blade design using a Navier-Stokes solver and artificial neural network, 1998, ASME 98-GT-4 and Journal of Turbomachinery, pp. 326–332.

Pierret S.: Turbomachinery blade design using a Navier-Stokes solver and artificial neural network, VKI Lecture Series 1997–05, Inverse design and optimisation methods.

Three-dimensional blade design by means of an artificial neural network and Navier-Stokes solver, VKI Lecture Series 1999-02: Turbomachinery Blade Design Systems, February 8–12 1999, 38 pages.

Pierret S.: Designing Turbomachinery Blades by Means of the Function Approximation concept based on Artificial Neural Network, Genetic Algorithm, and the Navier-Stokes Equations, PhD thesis, Faculté polytechnique de Mons and von Karman Institute, 1999.

Pierret S., Gouverneur B., Demeulenaere A., Hirsch C., Van den Braembussche R.: Designing turbomachinery blades with the function approximation concept and the navier-stokes equations, 8th AIAA/ NASA/ USAF/ ISSMO Symposium on MDO, Sep 6–8, 2000 / Long-Beach, CA, 11 pages AIAA 2000–4879.

Materials Handbook, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, 1990, Volume 22nd Edition.

Guerra M., Schmidt C., McClure J.C., Murr L.E., Nunes A.C.: Flow patterns during friction stir welding, Materials Characterization, 2003, vol. 49, pp. 95–101.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

De Vuyst, T., D’Alvise, L., Simar, A. et al. Finite Element Modelling of Friction Stir Welding of Aluminium Alloy Plates-Inverse Analysis using a Genetic Algorithm. Weld World 49, 47–55 (2005). https://doi.org/10.1007/BF03266475

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03266475