Abstract

Among the elevated temperature performance of gaskets, their mechanical and tightness integrity in flammable services due to fires is a key consideration necessary to provide gasket users with a safe gasket. This is particularly true since, of the numerous non-asbestos products now on the market, some would appear to have questionable integrity at elevated temperature as compared to that of the traditional asbestos products. Therefore, fire exposure survivability is an important aspect of gasket qualification for many process applications and the evaluation of the fire resistance is a key property to be considered for the acceptance of new products.

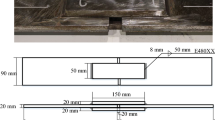

This paper summarizes the background on the development of the PVRC simulated fire testing program. The first part is concerned with fire test considerations and the early development of simple fire test procedures, the FIRS tests, based on the mechanical integrity of gasket materials after exposure to simulated fire conditions. This work was commissioned by the MTI (Materials Technology Institute of the Chemical Process Industries). Test results obtained on different types of sheet gasket materials (asbestos and non-asbestos), using these procedures, are discussed and the suitability of each procedure is analyzed. Upgrading possibilities are also reviewed.

The second part deals with a more recent and a more sophisticated fire survival test based on the joint tightness under a simulated fire exposure. With the PVRC financial support through Project 88-16 (referred to as Phase I) and Project 89-03 (referred to as Phases II and III), the development of a Fire Tightness Tests procedure (FITT) was made possible. In order to minimize development work, the PVRC HOIT tightness test concept was used. Several proposed Fire Tightness Test (FITO procedures were investigated on various sheet gasket materials (asbestos and non-asbestos) and composite gaskets (spiral wound gaskets).

Useful correlations of test results obtained with the FIRS and the FITT procedures were possible through these developments. A FIRS test could thus suffice to characterize the fire resistance of sheet gaskets, unless proof of tightness has to be made. The FITT test, on the other hand, is better adapted to composite gaskets (Double jacketed, spiral wound, etc.).

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

American Petroleum Institute (API), “Fire Test for Soft-Seated Quarter-Turn Valves”, API Standard 607, Third Edition, November 1985.

J.R. Payne, A. Bazergui, M. Derenne, L. Marchand, “Evaluation of Test Methods for Asbestos Replacement Gasket Materials,” MTI Publication No. 36, Materials Technology Institute of the Chemical Process Industries.

J.R. Payne, M. Derenne, A. Bazergui, “Estimating Elevated Temperature Gasket Performance with ATRS Tests,” 1989 SAE International Congress and Exhibition, Detroit, Feb. 1989, paper SAE, No. 890277 (also SAE Transactions 1989).

A. Bazergui, L. Marchand, “Development of Tightness Tests Procedures for Gaskets in Elevated Temperature Service,” Welding Research Council Bulletin, N.Y., WRC 339, Dec. 1988, pp. 1–20.

J.R. Payne, A. Bazergui, G.F. Leon, “Getting New Gasket Design Constants from Gasket Tightness Data,” Experimental Techniques, Society for Experimental Mechanics. Vol. 12, No. 11, November 1988

J.R. Payne, R.T. Mueller, A. Bazergui, “A. Gasket Qualification Test Scheme for Petrochemical Plants, Part I-Test Methods and Application Results,” PVP-ASME/JSME, Honolulu, Vol. 158, pp. 53–68, Jul. 1989.

J.R. Payne, R.T. Mueller, A. Bazergui, “A Gasket Qualification Test Scheme for Petrochemical Plants, Part II-Quality Criteria and Evaluation Schemes,” PVP-ASME/JSME, Honolulu, Vol. 158, pp. 69–79, Jul. 1989.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 1992 Springer Science+Business Media Dordrecht

About this chapter

Cite this chapter

Derenne, M., Payne, J.R., Marchand, L., Bazergui, A. (1992). Development of Test Procedures For Fire Resistance Qualification of Gaskets. In: Nau, B.S. (eds) Fluid Sealing. Fluid Mechanics and its Applications, vol 8. Springer, Dordrecht. https://doi.org/10.1007/978-94-011-2412-6_13

Download citation

DOI: https://doi.org/10.1007/978-94-011-2412-6_13

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-010-5064-7

Online ISBN: 978-94-011-2412-6

eBook Packages: Springer Book Archive