Abstract

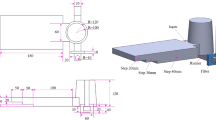

This work focuses on the effects of ultrasonic melt treatment (UST) during direct-chill (DC) casting on the temperature distribution across the billet, sump profile, and the resulting microstructure. Two AA6008 billets were cast; one was treated with UST in the hot top while the other was not. To determine the temperature distribution along the billet, multi-point temperature measurements were made across the radii of both billets. The sump profile was also analyzed through macrostructure analysis, after Zn was poured into the sump, while structure refinement was quantified through grain-size measurements. A numerical model of ultrasound-assisted DC casting is validated using the temperature measurements. As an outcome, this study provides information on the extent to which UST affects the sump profile and the corresponding changes in the microstructure. The knowledge gained from this study paves the way towards optimization of UST parameters in DC casting.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Granger DA (1989) Ingot casting in the aluminum industry. In: Treatise on Materials Science & Technology. Elsevier, pp 109–135. https://doi.org/10.1016/B978-0-12-341831-9.50009-7

Grandfield JF, Eskin DG, Bainbridge IF (2013) Direct-Chill Casting of Light Alloys: Science and Technology. John Wiley & Sons, Inc., Hoboken, NJ, USA

Murty BS, Kori SA, Chakraborty M (2002) Grain refinement of aluminium and its alloys by heterogeneous nucleation and alloying. International Materials Reviews 47:3–29. https://doi.org/10.1179/095066001225001049

Eskin GI, Eskin DG (2015) Ultrasonic Treatment of Light Alloy Melts, 2nd ed. CRC Press

Tzanakis I, Xu WW, Eskin DG, et al (2015) In situ observation and analysis of ultrasonic capillary effect in molten aluminium. Ultrasonics Sonochemistry 27:72–80. https://doi.org/10.1016/j.ultsonch.2015.04.029

Han Q (2015) Ultrasonic Processing of Materials. Metall and Materi Trans B 46:1603–1614. https://doi.org/10.1007/s11663-014-0266-x

Tzanakis I, Xu WW, Lebon GSB, et al (2015) In Situ Synchrotron Radiography and Spectrum Analysis of Transient Cavitation Bubbles in Molten Aluminium Alloy. Physics Procedia 70:841–845. https://doi.org/10.1016/j.phpro.2015.08.172

Lebon GSB, Tzanakis I, Pericleous K, et al (2019) Ultrasonic liquid metal processing: The essential role of cavitation bubbles in controlling acoustic streaming. Ultrasonics Sonochemistry 55:243–255. https://doi.org/10.1016/j.ultsonch.2019.01.021

Eskin DG (2017) Ultrasonic processing of molten and solidifying aluminium alloys: overview and outlook. Materials Science and Technology, 33:636–645. https://doi.org/10.1080/02670836.2016.1162415

Salloum-Abou-Jaoude G, Eskin DG, Lebon GSB, et al (2019) Altering the Microstructure Morphology by Ultrasound Melt Processing During 6XXX Aluminium DC-Casting. In: Chesonis C (ed) Light Metals 2019. Springer International Publishing, Cham, pp 1605–1610

Zhang L, Eskin DG, Miroux A, et al (2012) Effect of inlet geometry on macrosegregation during the direct chill casting of 7050 alloy billets: experiments and computer modelling. IOP Conf Ser: Mater Sci Eng 33:012019. https://doi.org/10.1088/1757-899X/33/1/012019

Subroto T, Miroux A, Mortensen D, et al (2012) Semi-quantitative predictions of hot tearing and cold cracking in aluminum DC casting using numerical process simulator. IOP Conf Ser: Mater Sci Eng 33:012068. https://doi.org/10.1088/1757-899X/33/1/012068

Lebon GSB, Salloum-Abou-Jaoude G, Eskin D, et al (2019) Numerical modelling of acoustic streaming during the ultrasonic melt treatment of direct-chill (DC) casting. Ultrasonics Sonochemistry 54:171–182. https://doi.org/10.1016/j.ultsonch.2019.02.002

Nadella R, Eskin DG, Du Q, Katgerman L (2008) Macrosegregation in direct-chill casting of aluminium alloys. Progress in Materials Science 53:421–480. https://doi.org/10.1016/j.pmatsci.2007.10.001

Yu KC, Guo SJ, Nagaumi H (2016) Evaluation on the Accuracies of Sump Depth Measurements during DC Casting Process of 7050 Alloy. MSF 877:78–83. https://doi.org/10.4028/www.scientific.net/MSF.877.78

Acknowledgements

Financial support from EPSRC (UK) under projects UltraMelt2 (EP/R011001/1, EP/R011044/1 and EP/R011095/1) and Future LiME Hub (EP/N007638/1) is gratefully acknowledged. The authors are thankful for the support of Constellium in running DC casting experiments in the AMCC/BCAST and Dr. N. Barekar for his help on macrostructure sample preparation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Subroto, T. et al. (2021). Effect of Ultrasonic Melt Treatment on the Sump Profile and Microstructure of a Direct-Chill Cast AA6008 Aluminum Alloy. In: Perander, L. (eds) Light Metals 2021. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-65396-5_118

Download citation

DOI: https://doi.org/10.1007/978-3-030-65396-5_118

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-65395-8

Online ISBN: 978-3-030-65396-5

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)