Abstract

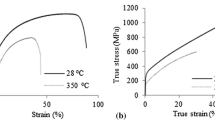

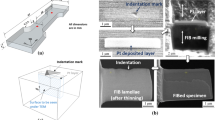

An attempt was made to track plastic tensile deformation modes operating in bulk ultrafine-grained austenitic stainless steel with mono- (maximum at ~0.6 μm) and bimodal-type (minimum at ~0.5 μm and maximum at ~1.65 μm) grain size distributions produced by cyclic thermal processing. Post tensile deformation electron backscatter diffraction studies were conducted to analyse the impact of grain size distribution on plastic deformation characteristics. The study revealed extensive strain localisation in the monomodal-type grain size distribution, leading to poor strain-hardening behaviour. On the other hand, the bimodal-type distribution disclosed a conventional dislocation-mediated deformation mechanism operating in the coarse grains, while it was restricted to initial small strains in ultrafine austenite grains. The subsequent deformation process in these ultrafine austenite grains was dictated by nucleation and autocatalytic growth of strain-induced α′-martensite. The observed martensitic transformation of ultrafine austenite grains in preference to coarse grains was attributed to activation of local ‘grain to grain’ interactions.

Similar content being viewed by others

References

K. Tomimura, S. Takaki, S. Tanimoto, Y. Tokunaga, Optimal chemical composition in Fe–Cr–Ni alloys for ultra grain refining by reversion from deformation induced martensite. ISIJ Int. 31, 721–727 (1991)

K. Tomimura, S. Takaki, Y. Tokunaga, Reversion mechanism from deformation induced martensite to austenite in metastable austenitic stainless steels. ISIJ Int. 31, 1431–1437 (1991)

S. Takaki, K. Tomimura, S. Ueda, Effect of pre-cold-working on diffusional reversion of deformation induced martensite in metastable austenitic stainless steel. ISIJ Int. 34, 522–527 (1994)

Y.Q. Ma, J.E. Jin, Y.K. Lee, A repetitive thermo-mechanical process to produce nano-crystalline in a metastable austenitic steel. Scripta Mater. 52, 1311–1315 (2005)

J.E. Jin, Y.S. Jung, Y.K. Lee, Effect of grain size on the uniform ductility of a bulk ultrafine-grained alloy. Mater. Sci. Eng. A 449–451, 786–789 (2007)

G.L. Huang, D.K. Matlock, G. Krauss, Martensite formation, strain rate sensitivity and deformation behaviour of type 304 stainless steel sheet. Metall. Trans. A 20A, 1239–1246 (1989)

K. Nohara, Y. Ono, N. Ohashi, Composition and grain size dependencies of strain-induced martensitic transformation in metastable austenitic stainless steel. J. Iron Steel Inst. Jpn. 63, 772–782 (1977)

H. Mirzadeh, A. Najafizadeh, Correlation between processing parameters and strain-induced martensitic transformation in cold worked AISI 301 stainless steel. Mater. Charact. 59, 1650–1654 (2008)

Y.-S. Jung, Y.-K. Lee, D.K. Matlock, M.C. Mataya, Effect of grain size on strain-induced martensitic transformation start temperature in an ultrafine grained metastable austenitic stainless steel. Metall. Mater. Int. 17, 553–556 (2011)

S.F. Peterson, M.C. Mataya, D.K. Matlock, The formability of austenitic stainless steels. J. Met. 49, 54–58 (1997)

B. Ravi Kumar, B. Mahato, S. Sharma, J.K. Sahu, Effect of cyclic thermal process on ultrafine grain formation in AISI 304l austenitic stainless steel. Metall. Mater. Trans. A 40A, 3226–3234 (2009)

B. Ravi Kumar, S. Sharma, B. Mahato, Formation of ultrafine grained microstructure in the austenitic stainless steel and its impact on tensile properties. Mater. Sci. Eng. A 528, 2209–2216 (2011)

C.-S. Yoo, Y.-M. Park, Y.-S. Jung, Y.-K. Lee, Effect of grain size on transformation-induced plasticity in an ultrafine-grained metastable austenitic stainless steel. Scripta Mater. 59, 71–74 (2008)

D. Farkas, H. Van Swygenhoven, P.M. Derlet, Intergranular fracture in nanocrystalline metals. Phys. Rev. B 66, 060101-1–060101-4 (2002)

Y.M. Wang, K. Wang, D. Pan, K. Lu, K.J. Hemker, E. Ma, Micro sample tensile testing of nanocrystalline copper. Scripta Mater. 48, 1581–1586 (2003)

K.S. Kumar, S. Suresh, M.F. Chisholm, J.A. Hortin, P. Wang, Deformation of electro-deposited nanocrystalline nickel. Acta Mater. 51, 387–405 (2003)

Q.M. Wei, D. Jia, K.T. Ramesh, E. Ma, Evolution and microstructure of shear bands in nanostructured Fe. Appl. Phys. Lett. 81, 1240–1242 (2002)

Y.M. Wang, E. Ma, Strain hardening, strain rate sensitivity, and ductility of nanostructured metals. Mater. Sci. Eng. A 375–377, 46–52 (2004)

Y.M. Wang, E. Ma, Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater. 52, 1699–1709 (2004)

E. Ma, Eight routes to improve the tensile ductility of bulk nanostructured metals and alloys. J. Met. 58, 49–53 (2006)

S. Berbenni, V. Favier, M. Berveiller, Impact of the grain size distribution on the yield stress of heterogeneous materials. Int. J. Plast. 23, 114–142 (2007)

B. Raeisinia, C.W. Sinclair, W.J. Poole, C.N. Tome, On impact of grain size distribution on the plastic behaviour of polycrystalline metals. Model. Simul. Mater. Sci. Eng. 16, 1–15 (2008)

K. Kako, E. Kawakami, J. Ohta, M. Mayuzumi, Effects of various alloying elements on tensile properties of high-purity Fe-18Cr-(14–16) Ni alloys at room temperature. Mater. Trans. 43, 155–162 (2002)

S. Takaki, Y. Tokunaga, in Ultra Grain Refining in Metastable Austenitic Stainless Steel. Proc Innovation stainless steels, AIM, Florence (1993), pp. 327–332

S. Rajasekhara, P.J. Ferreira, L.P. Karjalainen, A. Kyrolainen, Hall–Petch behavior in ultra-fine-grained AISI 301LN stainless steel. Metall. Mater. Trans. A 38A, 1202–1210 (2007)

K.P. Staudhammer, L.E. Murr, S.S. Hecker, Nucleation and evolution of strain-induced martensitic (b.c.c.) embryos and substructure in stainless steel: a transmission electron microscope study. Acta Metall. 31, 267–274 (1983)

S. Takaki, K. Kawasaki, Y. Kimura, Mechanical properties of ultra fine grained steels. J. Mater. Process. Technol. 117, 359–363 (2001)

Y.K. Lee, J.E. Jin, Y.Q. Ma, Transformation-induced extraordinary ductility in an ultrafine-grained alloy with nanosized precipitates. Scripta Mater. 57, 707–710 (2007)

P. Hedstrom, U. Lienert, J. Almer, M. Oden, Stepwise transformation behavior of the strain-induced martensitic transformation in a metastable stainless steel. Scripta Mater. 56, 213–216 (2007)

Acknowledgments

The authors are grateful to the Director of the National Metallurgical Laboratory for supporting this work. The authors also wish to record their gratitude to Ms. Sailaja Sharma, PhD scholar for her assistance during the experiments. This work was financially supported by the Department of Science and Technology, Government of India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ravi Kumar, B., Gujral, A. Plastic Deformation Modes in Mono- and Bimodal-Type Ultrafine-Grained Austenitic Stainless Steel. Metallogr. Microstruct. Anal. 3, 397–407 (2014). https://doi.org/10.1007/s13632-014-0152-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-014-0152-6