Abstract

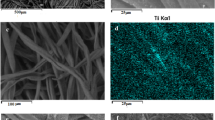

A new approach for dyeing and functional finishing for cotton fabric using Henna extract and TiO2 nano-sol was investigated. In this study, 3-chloro-2-hydroxy propyl trimethylammonium chloride was used to substitute metallic mordants (heavy-metal salts) in pre-treating cotton fabric. This eventually will prevent heavy metal pollution as well as obtain dyeing without addition of salt. TiO2 nano-sol was prepared by sol-gel method using different amounts of tetraisopropyl orthotitanate (TTIP) and applied on cationized cotton fabrics using the same finishing formulation and treatment sequence. Treated fabrics were then dyed with Henna extract at different dyeing temperatures (60 ℃, 80 ℃, and 90 ℃). TiO2 nanoparticles were characterized by transmission electron microscopy (TEM). The chemical and morphological structures of the dyed fabrics were characterized by attenuated total reflection-Fourier transform infrared (ATR-FTIR), scanning electron microscopy (SEM), and X-ray diffractometry (XRD). Color strength, fastness properties (washing, rubbing, and light), UV-blocking, antibacterial activity, and tensile strength were investigated. Samples treated with TiO2 and dyed with Henna extract exhibited outstanding enhancement in both the UV protection and antibacterial efficacy with minimal impact on color depth and tensile strength. Enhancement or decrement in the UV protection, antibacterial activity and dyeing properties are governed by the amount of TTIP and the dyeing temperature.

Similar content being viewed by others

References

E. Lichtfouse, J. Schwarzbauer, and D. Robert, “Green Materials for Energy, Products and Depollution”, Vol. 3, pp.229–281, Springer, Dijon, 2013.

A. K. Samanta and A. Konar, Natural Dyes, 3, 29 (2011).

N. A. Ibrahim, A. R. El-Gamal, M. Gouda, and F. Mahrous, Carbohydr. Polym., 82, 1205 (2010).

S. Ali, T. Hussain, and R. Nawaz, J. Clean Prod., 17, 61 (2009).

J. Iqbal, I. A. Bhatti, and S. Adeel, Indian J. Fibre Text. Res., 33, 157 (2008).

F. Rehman, A. Shahid, Q. Summia, B. A. Ijaz, S. Muhammad, and Z. Mohammad, Radait. Phys. Chem., 81, 1752 (2012).

M. S. Khalil-Abad, M. E. Yazdanshenas, and M. R. Nateghi, Cellulose., 16, 1147 (2009).

A. Farouk, S. Sharaf, and M. M. Abd El-Hady, Int. J. Biol. Macromol., 61, 230 (2013).

O. K. Alebeid and T. Zhao, Text. Res. J., 85, 449 (2015).

N. Ibrahim, R. Refaie, and A. Ahmed, J. Ind. Text., 40, 65 (2010).

A. C. Patino, C. Rodriguez, C. Caballero, G. Navarro, A. Canal, and J. M. Canal, Cellulose, 18, 1073 (2011).

M. M. Montazer, R. M. A. Malek, and A. Rahimi, Fiber. Polym., 8, 608 (2007).

D. Fakin, N. Veronovski, A. Ojstršek, and M. Božic, Carbohydr. Polym., 88, 992 (2012).

H. Zhang, L. Zhu, and R. Sun, J. Eng. Fiber Fab., 9, 67 (2014).

E. Pakdel and W. A. Daoud, J. Colloid Interface Sci., 401, 1 (2013).

J. H. Cai, J. W. Huang, H. C. Yu, and L. N. Ji, Int. J. Photoenergy, 2012, 1 (2012).

R. Vijayalakshmi and V. Rajendran, Arch. Appl. Sci. Res., 4, 1183 (2012).

N. A. Ibrahim, E. M. R. El-Zairy, W. A. Abdalla, and H. M. Khalil, Carbohydr. Polym., 92, 1386 (2013).

U. Akpan and B. Hameed, J. Hazard. Mater., 170, 520 (2009).

M. N. Micheal, F. M. Tera, and S. F. Ibrahim, J. Appl. Polym. Sci., 89, 1897 (2002).

S. S. Ugur, M. Sariišik, and A. H. Aktas, Fiber. Polym., 12, 190 (2011).

M. Akgun, B. Becerir, and H. Alpay, Acta Facultatis Medicae Naissensis, 27, 301 (2010).

N. Abidi, E. Hequet, S. Tarimala, and L. L. Dai, J. Appl. Polym. Sci., 104, 111 (2007).

M. Kannahi and K. Vinotha, Int. J. Curr. Microbiol. Appl. Sci., 2, 342 (2013).

P. Arun, K. Purushotham, and V. Kumari, Int. J. Pharm. Technol. Res., 2, 1178 (2010).

W. Jiang, K. Yang, R. W. Vachet, and B. Xing, Langmuir, 26, 18071 (2010).

V. Sundaram, I. K. R. Krishna, and S. Sreenivasan, “Handbook of Methods of Tests for Cotton Fibers, Yarns and Fabrics”, p.61, CIRCOT (ICAR), Mumbai, 2004.

S. Hashemikia and M. Montazer, Appl. Catal. A-Gen., 414, 200 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Alebeid, O.K., Zhao, T. & Seedahmed, A.I. Dyeing and functional finishing of cotton fabric using Henna extract and TiO2 Nano-sol. Fibers Polym 16, 1303–1311 (2015). https://doi.org/10.1007/s12221-015-1303-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-015-1303-3