Abstract

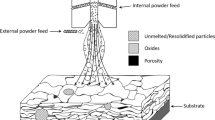

Plasma spraying at very low pressure (50-200 Pa) is significantly different from atmospheric plasma conditions (APS). By applying powder feedstock, it is possible to fragment the particles into very small clusters or even to evaporate the material. As a consequence, the deposition mechanisms and the resulting coating microstructures could be quite different compared to conventional APS liquid splat deposition. Thin and dense ceramic coatings as well as columnar-structured strain-tolerant coatings with low thermal conductivity can be achieved offering new possibilities for application in energy systems. To exploit the potential of such a gas phase deposition from plasma spray-based processes, the deposition mechanisms and their dependency on process conditions must be better understood. Thus, plasma conditions were investigated by optical emission spectroscopy. Coating experiments were performed, partially at extreme conditions. Based on the observed microstructures, a phenomenological model is developed to identify basic growth mechanisms.

Similar content being viewed by others

References

C. Verdy, C. Zhang, D. Sokolov, H. Liao, D. Klein, and C. Coddet, Gas-tight Coatings Produced by Very Low Pressure Plasma Spraying, Thermal Spray 2008: Thermal Spray Crossing Borders, on CD-ROM, E. Lugscheider, Ed., June 02-04, 2008 (Maastricht, The Netherlands), Verlag für Schweißen und verwandte Verfahren, 2008, p 398-402

G. Mauer, R. Vaßen, and D. Stöver, Thin and Dense Ceramic Coatings by Plasma Spraying at Very Low Pressure, J. Therm. Spray Technol., 2010, 19(1-2), p 495-501

L. Zhu, N. Zhang, B. Zhang, F. Sun, R. Bolot, M.-P. Planche, H. Liao, and C. Coddet, Very Low Pressure Plasma Sprayed Alumina and Yttria-Stabilized Zirconia Thin Dense Coatings Using a Modified Transferred Arc Plasma Torch, Appl. Surf. Sci., 2011, 258(4), p 1422-1428

K. von Niessen and M. Gindrat, Plasma Spray-PVD: A New Thermal Spray Process to Deposit Out of the Vapor Phase, J. Therm. Spray Technol., 2011, 20(4), p 736-743

K. von Niessen, M. Gindrat, and A. Refke, Vapor Phase Deposition Using Plasma Spray-PVD, Therm. Spray Technol., 2010, 19(1-2), p 502-509

B. Jodoin, M. Gindrat, J.-L. Dorier, C. Hollenstein, M. Loch, and G. Barbezat, Modeling and Diagnostics of a Supersonic DC Plasma Jet Expanding at Low Pressure, International Thermal Spray Conference, E. Lugscheider, C.C. Berndt, Ed., March 04-06, 2002 (Essen, Germany), Verlag für Schweißen und verwandte Verfahren DVS-Verlag, 2002, p 716-720

J. Hafiz, R. Mukherjee, X. Wang, P.H. McMurry, J.V.R. Heberlein, and S.L. Girshick, Hypersonic Plasma Particle Deposition-A Hybrid between Plasma Spraying and Vapor Deposition, J. Therm. Spray Technol., 2006, 15(4), p 822-826

J. Aubreton, M.F. Elchinger, V. Rat, and P. Fauchais, Two-Temperature Transport Coefficients in Argon-Helium Thermal Plasmas, J. Phys. D, 2004, 37, p 34-41

G. Mauer, R. Vaßen, and D. Stöver, Plasma and Particle Temperature Measurements in Thermal Spray: Approaches and Applications, J. Therm. Spray Technol., 2011, 20(3), p 391-406

H. Kaßner, R. Siegert, D. Hathiramani, R. Vaßen, and D. Stöver, Application of Suspension Plasma Spraying (SPS) for Manufacture of Ceramic Coatings, J. Therm. Spray Technol., 2008, 17(1), p 115-123

K. VanEvery, M.J.M. Krane, R.W. Trice, H. Wang, W. Porter, M. Besser, D. Sordelet, J. Ilavsky, and J. Almer, Column Formation in Suspension Plasma-Sprayed Coatings and Resultant Thermal Properties, J. Therm. Spray Technol., 2011, 20(4), p 817-828

J.A. Venables, G.D.T. Spiller, and M. Hanbücken, Nucleation and Growth of Thin Films, Rep. Prog. Phys., 1984, 47, p 399-459

J.A. Thornton, High Rate Thick Film Growth, Ann. Rev. Mater. Sci., 1977, 7, p 239-260

B.A. Movchan and A.V. Demchishin, Study of the Structure and Properties of Thick Vacuum Condensates of Nickel, Titanium, Tungsten, Aluminum Oxide and Zirconium Dioxide, Phys. Met. Metallogr., 1969, 28(4), p 83-90

J.A. Thornton, Influence of Apparatus Geometry and Deposition Conditions on Structure and Topography of Thick Sputtered Coatings, J. Vac. Sci. Technol., 1974, 11(4), p 666-670

J.A. Thornton, Influence of Substrate Temperature and Deposition Rate on Structure of Thick Sputtered Cu Coatings, J. Vac. Sci. Technol., 1975, 12(4), p 830-835

R. Messier, A.P. Giri, and R.A. Roy, Revised Structure Zone Model for Thin Film Physical Structure, J. Vac. Sci. Technol., A, 1984, 2(2), p 500-503

J. Musil, S. Kadlec, V. Valvoda, R. Kužel, and R. Černý, Ion-Assisted Sputtering if TiN Films, Surf. Coat. Technol., 1990, 43/44, p 259-269

X. Wang and A. Atkinson, Microstructure Evolution in Thin Zirconia Films: Experimental Observation and Modeling, Acta Mater., 2011, 59, p 2514-2525

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mauer, G., Hospach, A., Zotov, N. et al. Process Conditions and Microstructures of Ceramic Coatings by Gas Phase Deposition Based on Plasma Spraying. J Therm Spray Tech 22, 83–89 (2013). https://doi.org/10.1007/s11666-012-9838-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-012-9838-y