Abstract

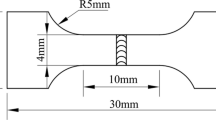

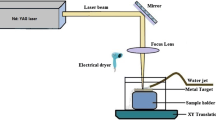

During the valve fabrication, hard metal is welded to stainless steel or invar alloy for sealing purposes because of its good heat resistance operating at 500 °C. However, WC (tungsten carbide) dissolution in weld pool softens the hard metal and decreases mechanical properties near the hard metal/weld interface. In order to analyze the WC dissolution in welded joint, joining of hard metal and invar alloy was carried out using laser-tungsten inert gas hybrid welding method. Microstructures of the weld region, chemical composition were investigated using optical microscope, scanning electron microscopy, and EDAX, respectively. Mechanical properties such as microhardness and four-point bend strength test were performed. Larger and smaller WC dissolution and WC dissolution through transition layer based on thermo-dynamics were discussed. The results thus indicate that WC dissolution led to cellular microstructure, columnar crystal, and transition layer under the effect of laser beam and tungsten arc. WC dissolution was affected by metal ions Fe+, Ni+, Co+ exchange in W-M-C system, and WC grain growth was driven by forces caused by laser beam and tungsten arc in larger WC, smaller WC, and liquid Fe, Ni systems.

Similar content being viewed by others

References

G.M. Kadzioka, W. Zarek, E. Talik, and E. Popiel, Mössbauer Investigations and Photoemission Studies of the Fe 3s Spin Splitting in Some Fe-Ni Alloys, Acta Phys. Pol., A, 2008, 114, p 1493–1500

V.M. Nadutov, S.G. Kosintsev, O. Svystunov, V.M. Garamus, R. Willumeit, H. Eckerlebe, T. Ericsson, and H. Annersten, Anti-Invar Properties and Magnetic Order in fcc Fe–Ni–C Alloy, J. Magn. Magn. Mater., 2011, 323, p 2786–2791

R.R. Mulyukov, K.Y. Mulyukov, and I.M. Safarov, Effect of Severe Plastic Deformation on the Properties of the Fe-36% Ni Invar Alloy, Phys. Met. Metallogr., 2006, 102, p 91–96

Z.W. Yang, L.X. Zhang, Q. Xue, P. He, and J.C. Feng, Interfacial Microstructure and Mechanical Property of SiO2-BN Ceramics and Invar Joint Brazed with Ag-Cu-Ti Active Filler Metal, Mater. Sci. Eng. A, 2012, 534, p 309–313

V.A. Shabashov, A.V. Litvinov, N.V. Kataeva, K.A. Lyashkov, S.I. Novikov, and S.G. Titov, Formation of Boron Solid Solution in Fe-Ni Invar Upon Severe Plastic Deformation, Phys. Met. Metallogr., 2011, 112, p 245–255

P.Q. Xu, X.J. Zhao, G.X. Xu, L.N. Li, and Z.S. Yu, Microstructure Characterisation and CTE Study of Fe-42Ni-Nb Invar Alloys, Mater. Sci. Tech Lond, 2011, 27, p 655–660

T.K. Ha, K.D. Lee, J.H. Song, and H.T. Jeong, Effect of Aging Treatment Conditions on the Microstructure and Strength of Fe-36Ni Based Invar Alloy, Key Engineering Materials, The Mechanical Behavior of Materials X Part 1: 10th International Conference on the Mechanical Behaviour of Materials, Vol. 345–346, 2007, p 109–112

O.A. Khomenko, Origin and Specific Features of Invar Anomalies of Physical Properties: Fe-Ni Alloys with an FCC Lattice, Phys. Met. Metallogr., 2007, 104, p 146–156

M.K. Kim, J. Namkung, and Y.S. Ahn, The Effect of Si and Microstructure Evolution on the Thermal Expansion Properties of Fe-42Ni-Si Alloy Strips, J. Mater. Sci., 2008, 43, p 3112–3117

A.I. Uvarov, V.A. Sandovskii, V.A. Kazantsev, E.I. Anufrieva, N.F. Vil’Danova, and Y.I. Filippov, Effect of Heat and Thermomechanical Treatments on the Structure and Physical and Mechanical Properties of the N30K10T3 Invar, Phys. Met. Metallogr., 2008, 105, p 45–55

V.M. Nadutov, Y.O. Svystunov, S.G. Kosintsev, and V.A. Tatarenko, Mössbauer Analysis and Magnetic Properties of Invar Fe-Ni-C and Fe-Ni-Mn-C Alloys, Hyperfine Interact., 2006, 168, p 929–935

W. Lee, B. Kwon, and S. Jung, Effect of Cr3C2 on the Microstructure and Mechanical Properties of the Brazed Joints WC-Co and Carbon Steel, Int. J. Refract. Met. H, 2006, 24, p 215–221

O. Kenichi and K. Mitsuhiko, Elasto-Plastic-Creep Characteristics of BAg8 Brazing Filler Metal Estimated by Tension-Strain Maintenance Test, Q. J. Jpn. Weld. Soc., 2009, 27, p 96–103

M.I. Barrena, J.M. Salazar, and L. Matesanz, Interfacial Microstructure and Mechanical Strength of WC-Co/90MnCrV8 Cold Work Tool Steel Diffusion Bonded Joint with Cu/Ni Electroplated Interlayer, Mater. Des., 2010, 31, p 3389–3394

L. Zhu, L.M. Luo, J. Luo, J. Li, and Y.C. Wu, Effect of Electroless Plating Ni-Cu-P Layer on the Wettability Between Cemented Carbides and Soldering Tins, Int. J. Refract. Met. H, 2012, 31, p 192–195

F. Andreatta, L. Matesanz, A.H. Akita, L. Paussa, L. Fedrizzi, C.S. Fugivara, J.M. Salazarb, and A.V. Benedettic, SAE 1045 steel/WC-Co/Ni-Cu-Ni/SAE 1045 Steel Joints Prepared by Dynamic Diffusion Bonding: Microelectrochemical Studies in 0.6 M NaCl solution, Electrochim. Acta, 2009, 55, p 551–559

J. Rodelas, G. Hilmas, and R.S. Mishra, Sinterbonding Cobalt-Cemented Tungsten Carbide to Tungsten Heavy Alloys, Int. J. Refract. Met. H, 2009, 27, p 835–841

N.L. Tian and Y.Q. Yang, Study of Laser Molten Welding of Cemented Carbides and Steel, Proc. SPIE, 1996, 2888, p 185–193

A. Costa, R.M. Miranda, and L. Quintino, Materials Behavior in Laser Welding of Hardmetals to Steel, Mater. Manuf. Process., 2006, 21, p 459–465

C. Barbatti, J. Garcia, and G. Liedl, Joining of Cemented Carbides to Steel by Laser Beam Welding, Materialwiss. Werkstofftech., 2007, 38, p 907–914

P.Q. Xu and X.J. Zhao, Analysis of Microstructure and Properties of Cemented Carbide and Invar Alloy Weldment, J. Mater. Eng. Perform., 2010, 19, p 294–300

P.Q. Xu, X.J. Zhao, D.X. Yang, and S. Yao, Study on Filler Metal (Ni-Fe-C) During GTAW of WC-30Co to 45 Carbon Steel, J. Mater. Sci., 2005, 40, p 6559–6564

P.Q. Xu, Dissimilar Welding of WC-Co Cemented Carbide to Ni42Fe50.9C0.6 Mn3.5Nb3 Invar Alloy by Laser-Tungsten Inert Gas Hybrid Welding, Mater. Des., 2011, 32, p 229–237

P.Q. Xu, D. Ma, and C.W. Ma. Analysis of WC Dissolution Phenomenon Happened in TIG Welded Joint of Cemented Carbide and Invar alloy. 2012 Int. Conf. Front. Mech. Eng. Mater. Eng., MEME2012, Hong Kong, July 27–29, 2012

G.S. Upadhyaya, Cemented Tungsten Carbides: Production, Properties, and Testing, Noyes Publications, Park Ridge, NJ, 1998

O. Eso, Z.G.Z. Fang, and A. Griffo, Kinetics of Cobalt Gradient Formation During the Liquid Phase Sintering of Functionally Graded WC-Co, Int. J. Refract. Met. H, 2007, 25, p 286–292

V.K. Sarin, Morphology of Eta Phase in Cemented WC-Co Alloys, Proc. 5th Int. Powder. Metall. Conf., Chicago, IL, 1976

Z.Y. Xu, Thermal Dynamics of Materials, Higher Education Press, Beijing, 2009, p 121–126

K. Mannesson, J. Jeppsson, A. Borgenstam, and J. Ågren, Carbide Grain Growth in Cemented Carbides, Acta Mater., 2011, 59, p 1912–1923

J. Weidow, S. Johansson, H.O. Andrén, and G. Wahnström, Transition Metal Solubilities in WC in Cemented Carbide Materials, J. Am. Ceram. Soc., 2011, 94, p 605–610

J.D. Harrison and C. Wagner, The Attack of Solid Alloys by Liquid Metals and Salt Melts, Acta Metall., 1959, 7, p 722–735

R.B. Adams and J.A. Pask, Fundamentals of Glass-to-Metal Bonding: VII, Wettability of Iron by Molten Sodium Silicate Containing Iron Oxide, J. Am. Ceram. Soc., 1961, 44, p 430–433

L.G. Hagan and S.F. Ravitz, Fundamentals of Glass-to-Metal Bonding: VI, Reaction Between Metallic Iron and Molten Sodium Disilicate, J. Am. Ceram. Soc., 1961, 44, p 428–429

R.M. Walser and R.W. Bene, First Phase Nucleation in Silicon-Transition-Metal Planar Interfaces, Appl. Phys. Lett., 1976, 28, p 624–625

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grants Number: 51105240). PQX thanks the Foundation support from Shanghai Municipal Education Commission and Dr. L. J. Li from Utah State University for the Visiting Research Fellowship Award, which gives him more research time and opportunities. And many thanks will be given to Dr. Bishal Silwal in Utah State University for his help during paper revision.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, P.Q., Ren, J.W., Zhang, P.L. et al. Analysis of Formation and Interfacial WC Dissolution Behavior of WC-Co/Invar Laser-TIG Welded Joints. J. of Materi Eng and Perform 22, 613–623 (2013). https://doi.org/10.1007/s11665-012-0279-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0279-z