Abstract

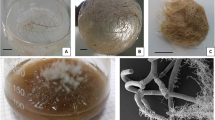

Present investigation involves hairy root cultivation of Azadirachta indica in a modified stirred tank reactor under optimized culture conditions for maximum volumetric productivity of azadirachtin. The selected hairy root line (Az-35) was induced via Agrobacterium rhizogenes LBA 920-mediated transformation of A. indica leaf explants (Coimbatore variety, India). Liquid culture of the hairy roots was developed in a modified Murashige and Skoog medium (MM2). To further enhance the productivity of azadirachtin, selected growth regulators (1.0 mg/l IAA and 0.025 mg/l GA3), permeabilizing agent (0.5 % v/v DNBP), a biotic elicitor (1 % v/v Curvularia (culture filtrate)) and an indirectly linked biosynthetic precursor (50 mg/l cholesterol) were added in the growth medium on 15th day of the hairy root cultivation period in shake flask. Highest azadirachtin production (113 mg/l) was obtained on 25th day of the growth cycle with a biomass of 21 g/l DW. Further, batch cultivation of hairy roots was carried out in a novel liquid-phase bioreactor configuration (modified stirred tank reactor with polyurethane foam as root support) to investigate the possible scale-up of the established A. indica hairy root culture. A biomass production of 15.2 g/l with azadirachtin accumulation in the hairy roots of 6.4 mg/g (97.28 mg/l) could be achieved after 25 days of the batch cultivation period, which was ~27 and ~14 % less biomass and azadirachtin concentration obtained respectively, in shake flasks. An overall volumetric productivity of 3.89 mg/(l day) of azadirachtin was obtained in the bioreactor.

Similar content being viewed by others

References

Schmutterer H (1990) Properties and potential of natural pesticides from the Neem trees, Azadirachta indica. Ann Rev Entomol 35:271–297

Mordue AJ, Blackwell A (1993) Azadirachtin: an update. J Insect Physiol 39:903–924

Prakash G, Bhojwani SS, Srivastava AK (2002) Production of azadirachtin from plant tissue culture: state of the art and future prospects. Biotechnol Bioprocess Eng 7:185–193

Srivastava S, Srivastava AK (2008) Recent advances of in vitro azadirachtin production. In: Ramawat KG, Merillon JM (eds) Biotechnology: bioactive molecules and medicinal plants. Springer, Germany, pp 234–250

Prakash G, Emmannuel CJSK, Srivastava AK (2005) Variability of azadirachtin in Azadirachta indica (neem) and batch kinetics studies of cell suspension culture. Biotechnol Bioprocess Eng 10:198–204

Prakash G, Srivastava AK (2005) Statistical media optimization for cell growth and azadirachtin production in Azadirachta indica (A. Juss) suspension cultures. Process Biochem 40:3795–3800

Prakash G, Srivastava AK (2006) Modeling of azadirachtin production by Azadirachta indica and its use for feed forward optimization studies. Biochem Eng 29:62–68

Prakash G, Srivastava AK (2007) Azadirachtin production in stirred tank reactors by Azadirachta indica suspension culture. Process Biochem 42:93–97

Prakash G, Srivastava AK (2008) Statistical elicitor optimization studies for the enhancement of azadirachtin production in bioreactor Azadirachta indica cell cultivation. Biochem Eng J 40:218–226

Giri A, Narasu ML (2000) Transgenic hairy roots: recent trends and applications. Biotechnol Adv 18:1–22

Srivastava S, Srivastava AK (2007) Hairy root culture for mass-production of high-value secondary metabolites. Crit Rev Biotechnol 27:29–43

Carvalho EB, Holihan S, Pearsall B, Curtis WR (1997) Effect of root morphology on reactor design and operation for production of chemicals. In: Doran P (ed) Hairy roots. Gordon and Breach Reading, UK, pp 151–167

Srivastava S, Srivastava AK (2012) Statistical medium optimization for enhanced azadirachtin production in hairy root culture of Azadirachta indica. In Vitro Cell Dev Biol Plant 48:73–84

Murashige T, Skoog F (1962) A revised medium for rapid growth and bioassays with tobacco tissue cultures. Physiol Plant 15:473–497

Gamborg OL, Miller RA, Ojima K (1968) Nutrient requirements of suspension cultures of soybean root cells. Exp Cell Res 50:151–158

Yan O, Hu Z, Tan RX, Wu J (2005) Efficient production and recovery of diterpenoid tanshinones in Salvia miltiorrhiza hairy root cultures with in situ adsorption, elicitation and semi-continuous operation. J Biotechnol 119:416–424

Srivastava S, Harsh S, Srivastava AK (2008) Use of NADH fluorescence measurement for on-line biomass estimation and characterization of metabolic status in bioreactor cultivation of plant cells for azadirachtin (a biopesticide) production. Process Biochem 43:1121–1123

Dubois M, Gilf KA, Hamilton JK, Roberts PA, Smith F (1956) Colorimetric method for determination of sugars and related substances. Anal Chem 28:350–356

Ünyayar S, Ünyayar A (2000) Production of auxin and abscisic acid by Phanerochaete chrysosporium ME446 immobilized on polyurethane foam. Turk J Biol 24:769–774

Choi YE, Kim YS, Paek KY (2006) Types and design of bioreactors for hairy root culture. In: Dutta Gupta S, Ibaraki Y (eds) Plant tissue culture engineering series: focus on biotechnology. Springer, Dordrecht, pp 161–171

Taya M, Yoyama A, Kondo O, Kobayashi T, Matsui C (1989) Growth characteristics of plant hairy roots and their culture in bioreactors. J Chem Eng Jpn 22:89–94

Muranaka T, Ohkawa H, Yamada Y (1993) Continuous production of scopolamine by a culture of Duboisia Leichhardtii hairy root clone in a bioreactor system. Appl Microbiol Biotechnol 40:219–223

Kondo O, Honda H, Taya M, Kobayashi T (1989) Comparison of growth properties of carrot hairy roots in various bioreactors. Appl Microbiol Biotechnol 32:291–294

Srivastava S, Srivastava AK (2012) In vitro cultivation of azadirachtin production by hairy root cultivation of Azadirachta indica in nutrient mist bioreactor. Appl Biochem Biotechnol 166:365–378

Srivastava S, Srivastava AK (2012) Strategies to overcome oxygen transfer limitations during hairy root cultivation of Azadiracta indica for enhanced azadirachtin production. Appl Biochem Biotechnol. doi:10.1007/s12010-011-9531-5

Acknowledgments

The financial support by Department of Biotechnology, Ministry of Science and Technology, New Delhi (India) for the execution of the above project is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Srivastava, S., Srivastava, A.K. Azadirachtin production by hairy root cultivation of Azadirachta indica in a modified stirred tank reactor. Bioprocess Biosyst Eng 35, 1549–1553 (2012). https://doi.org/10.1007/s00449-012-0745-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-012-0745-x