Abstract

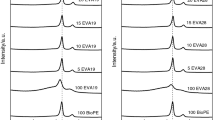

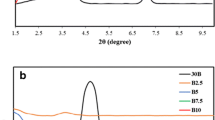

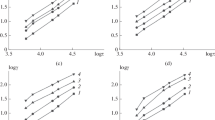

The electrical and rheological properties of an ethylene vinyl acetate (EVA) copolymer filled with bamboo charcoal were investigated. The composites were prepared by melt process in an internal batch mixer. Size distribution analysis showed that d(50) and d(90) values of the bamboo charcoal particles are 12.7 and 40 μm, respectively, with a mean diameter of 22 μm. Scanning electron microscopy proved that the particles of bamboo charcoal present a rectangular shape. The electrical percolation threshold was observed at 0.18 volume fraction (35 wt%) of bamboo. Beyond the percolation threshold, a considerable increase in electrical properties was observed up to a limit value of 10-2 S/m. The rheological percolation was studied from different rheological models. As a result, the rheological percolation threshold was observed at 0.3 volume fraction (50 wt%) of bamboo charcoal contents. So, the electrical percolation occurs before the rheological percolation. This is principally due to the filler’s characteristics such as the specific surface area, the aspect ratio, and the surface properties. Finally, the bamboo charcoal confers high electrical properties to the EVA composite without inducing strong changes in its viscoelastic properties.

Similar content being viewed by others

References

Balberg I (1987) Tunneling and nonuniversal conductivity in composite materials. Phys Rev Lett 59:1305–1308

Balberg I (2002) A comprehensive picture of the electrical phenomena in carbon black–polymer composites. Carbon 40:139–143

Barrau S, Demont P, Peigney A, Laurent C, Lacabanne C (2003) DC and AC conductivity of carbon nanotubes–polyepoxy composites. Macromolecules 36:5187–5194

Bauhofer W, Kovacs JZ (2009) A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos Sci Technol 69:1486–1498

Bose S, Bhattacharyya AR, Kulkarni AR, Poetschke P (2009) Electrical, rheological and morphological studies in co-continuous blends of polyamide 6 and acrylonitrile–butadiene–styrene with multiwall carbon nanotubes prepared by melt blending. Compos Sci Technol 69:365–372

Carrot C, Majesté JC, Olalla B, Fulchiron R (2010) On the use of the model proposed by Leonov for the explanation of a secondary plateau of the loss modulus in heterogeneous polymer–filler systems with agglomerates. Rheol Acta 49:513–527

Carrot C, Olalla B, Fulchiron R (2012) Relaxation of loose agglomerates of magnesium hydroxide in a polymer melt. Polymer 53:5560–5567

Cassagnau P (2008) Melt rheology of organoclay and fumed silica nanocomposites. Polymer 49:2183–2196

Chapartegui M, Markaide N, Florez S, Elizetxea C, Fernandez M, Santamaria A (2010) Specific rheological and electrical features of carbon nanotube dispersions in an epoxy matrix. Compos Sci Technol 70:879–884

Charman M, Leonardi F, Dominguez S, Bissuel C, Derail C (2011) Dispersion of multiwalled carbon nanotubes in a rubber matrix using an internal mixer: effects on rheological and electrical properties. J Polym Sci Part B: Polym Phys 49:1597–1604

Chattopadhyay SK, Khandal RK, Uppaluri R, Ghoshal AK (2010) Bamboo fiber reinforced polypropylene composites and their mechanical, thermal, and morphological properties. J Appl Polymer Sci 119:1619–1626

Choi SS (2002) Difference in bound rubber formation of silica and carbon black with styrene-butadiene rubber. Polym Adv Technol 13:466–474

Choi SS (2004) Effect of bound rubber on characteristics of highly filled styrene–butadiene rubber compounds with different types of carbon black. J Appl Polymer Sci 93:1001–1006

Dang ZM, Nan CW, Xie D, Zhang YH, Tjong SC (2004) Dielectric behavior and dependence of percolation threshold on the conductivity of fillers in polymer-semiconductor composites. Appl Phys Lett 85:97–99

Dang Z-M, Shehzad K, Zha J-W, Mujahid A, Hussain T, Nie J, Shi C-Y (2011) Complementary percolation characteristics of carbon fillers based electrically percolative thermoplastic elastomer composites. Compos Sci Technol 72:28–35

Du FM, Scogna RC, Zhou W, Brand S, Fischer JE, Winey KI (2004) Nanotube networks in polymer nanocomposites: rheology and electrical conductivity. Macromolecules 37:9048–9055

Dyre JC, Schroder TB (2000) Universality of ac conduction in disordered solids. Rev Mod Phys 72:873–892

German RM (1989) Particle packing characteristics. Metal Powder Industries Federation, Princeton

Huang S, Liu Z, Yin C, Wang Y, Gao Y, Chen C, Yang M (2012) Dynamic electrical and rheological percolation in isotactic poly(propylene)/carbon black composites. Macromol Mater Eng 297:51–59

Jonscher A (1977) The universal dielectric response. Nature 267:673–679

Kantarelis E, Liu JL, Yang WH, Blasiak W (2010) Sustainable valorization of bamboo via high-temperature steam pyrolysis for energy production and added value materials. Energy Fuel 24:6142–6150

Kovacs JZ, Velagala BS, Schulte K, Bauhofer W (2007) Two percolation thresholds in carbon nanotube epoxy composites. Compos Sci Technol 67:922–928

Krieger IM (1972) Rheology of monodisperse latices. Adv Colloid Interface Sci 3:111–136

Krieger IM, Dougherty TG (1959) A mechanism for non-Newtonian flow in suspensions of rigid spheres. Trans Soc Rheol 3:137–152

Krishnamoorti R, Giannelis EP (1997) Rheology of end-tethered polymer layered silicate nanocomposites. Macromolecules 30:4097–4102

Larson RG (1999) The structure and rheology of complex fluids. Oxford University Press, New York

Leboeuf M, Ghamri N, Brule B, Coupez T, Vergnes B (2008) Influence of mixing conditions on rheological behavior and electrical conductivity of polyamides filled with carbon black. Rheol Acta 47:201–212

Lee SH, Cho E, Jeon SH, Youn JR (2007) Rheological and electrical properties of polypropylene composites containing functionalized multi-walled carbon nanotubes and compatibilizers. Carbon 45:2810–2822

Lertwimolnun W, Vergnes B (2006) Effect of processing conditions on the formation of polypropylene/organoclay nanocomposites in a twin screw extruder. Polym Eng Sci 46:314–323

Levchenko V, Mamunya Y, Boiteux G, Lebovka M, Alcouffe P, Seytre G, Lebedev E (2011) Influence of organo-clay on electrical and mechanical properties of PP/MWCNT/OC nanocomposites. Eur Polym J 47:1351–1360

Leyva ME, Barra GMO, Moreira ACF, Soares BG, Khastgir D (2003) Electric, dielectric, and dynamic mechanical behavior of carbon black/styrene–butadiene–styrene composites. J Polym Sci Part B: Polym Phys 41:2983–2997

Li QS, Xu MS, Zhou GJ, Wang LQ (2010) Preparation and characterization of white bamboo charcoal PET fiber. Chin Chem Lett 21:995–998

Martins JN, Bassani TS, Barra GMO, Oliveira RVB (2010) Electrical and rheological percolation in poly(vinylidene fluoride)/multi-walled carbon nanotube nanocomposites. Polym Int 60:430–435

Mierczynska A, Mayne-L’Hermite M, Boiteux G, Jeszka JK (2007) Electrical and mechanical properties of carbon nanotube/ultrahigh-molecular-weight polyethylene composites prepared by a filler prelocalization method. J Appl Polymer Sci 105:158–168

Mingjie G (2004) Manual for bamboo charcoal production and utilization. Bamboo Engineering Research Center. E. Nanjing Forestry University

Pishvaei M, Graillat C, Cassagnau P, McKenna TF (2006) Modelling the zero shear viscosity of bimodal high solid content latex: calculation of the maximum packing fraction. Chem Eng Sci 61:5768–5780

Poetschke P, Abdel-Goad M, Pegel S, Jehnichen D, Mark JE, Zhou D, Heinrich G (2010) Comparisons among electrical and rheological properties of melt-mixed composites containing various carbon nanostructures. J Macromol Sci Part A-Pure Appl Chem 47:12–19

Qu M, Deng F, Kalkhoran SM, Gouldstone A, Robisson A, Van Vliet KJ (2011) Nanoscale visualization and multiscale mechanical implications of bound rubber interphases in rubber-carbon black nanocomposites. Soft Matter 7:1066–1077

Sherman RD, Middleman LM, Jacobs SM (1983) Electron-transport processes in conductor-filled polymers. Polym Eng Sci 23:36–46

Sohi NJS, Bhadra S, Khastgir D (2011) The effect of different carbon fillers on the electrical conductivity of ethylene vinyl acetate copolymer-based composites and the applicability of different conductivity models. Carbon 49:1349–1361

Song Y, Zheng Q (2011) Application of two phase model to linear viscoelasticity of reinforced rubbers. Polymer 52:593–596

Stauffer D (1979) Scaling theory of percolation clusters. Phys Rep-Rev Sect Phys Lett 54:1–74

Stauffer D (1985) Introduction to percolation theory. Taylor and Francis, London

Sumfleth J, Buschhorn ST, Schulte K (2011) Comparison of rheological and electrical percolation phenomena in carbon black and carbon nanotube filled epoxy polymers. J Mater Sci 46:659– 669

Vignaux-Nassiet V, Allal A, Montfort JP (1998) Emulsion models and rheology of filled polymers. Eur Polym J 34:309–322

Zhou Z, Wang S, Lu L, Zhang Y, Zhang Y (2007) Preparation and rheological characterization of poly(methyl methacrylate)/functionalized multi-walled carbon nanotubes composites. Compos Sci Technol 67:1861–1869

Zou JF, Yu ZZ, Pan YX, Fang XP, Ou YC (2002) Conductive mechanism of polymer/graphite conducting composites with low percolation threshold. J Polym Sci Part B: Polym Phys 40:954– 963

Acknowledgments

Bamboo charcoal particles have been kindly supplied by the company “Bamboo Fibers Technology” (Lahontan, France). The authors would like to thank the “Centre Technologique des Microstructures” of the University Lyon 1 (France).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belaïd, S., Boiteux, G. & Cassagnau, P. Rheological and electrical properties of EVA copolymer filled with bamboo charcoal. Rheol Acta 52, 75–84 (2013). https://doi.org/10.1007/s00397-012-0669-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-012-0669-z